Granite-like coating for thermal insulation type external wall of building and preparation method thereof

A technology for imitating granite coatings and building exterior walls, applied in the field of building materials, can solve the problems of attenuation of thermal insulation, unstable composition, shortened service life of thermal insulation coatings, etc., to improve adhesion, improve simulation, and thermal stability. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

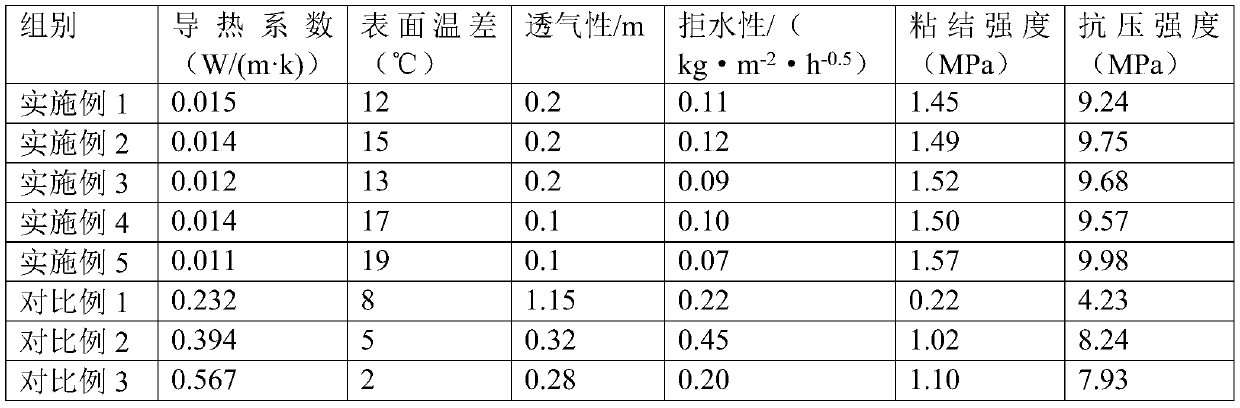

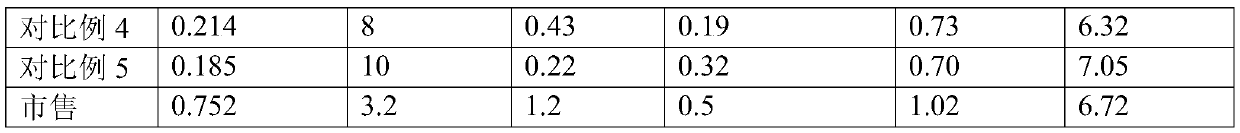

Examples

Embodiment 1

[0036] Example 1 Imitation Granite Coating for Exterior Wall of Thermal Insulation Building

[0037] Composition of raw materials (parts by weight): 200 parts of water, 10 parts of sodium carboxymethyl cellulose, 2 parts of polycarboxylate ammonium salt dispersant, 300 parts of granite stone powder, 50 parts of quartz sand, 30 parts of phase change energy storage material, mineral oil 2 parts of foaming agent, 20 parts of silicone acrylic emulsion, 10 parts of propylene glycol butyl ether, 1 part of isothiazolinone preservative.

[0038] The mesh number of the granite stone powder is 80-120 mesh, and the weight ratio of the 100-120 mesh granite stone powder accounts for 60%.

[0039] The preparation method of the phase change energy storage material is as follows:

[0040]S1. Diatomite treatment: Soak 22.5g of diatomite in 0.01mol / L dilute NaOH solution, wash it with water, and calcinate it in a muffle furnace at 1000°C for 3 hours, cool it, take it out, and grind it to 30-...

Embodiment 2

[0045] Example 2 Imitation Granite Coating for Exterior Wall of Thermal Insulation Building

[0046] Composition of raw materials (parts by weight): 300 parts of water, 20 parts of sodium carboxymethylcellulose, 5 parts of nonionic surface active dispersant, 400 parts of granite stone powder, 70 parts of quartz sand, 70 parts of phase change energy storage material, mineral oil Foam agent 6 parts, silicone acrylic emulsion 30 parts, propylene glycol butyl ether 20 parts, 1,2-benzisothiazolin-3-one 3 parts.

[0047] The mesh number of the granite stone powder is 80-120 mesh, wherein the weight ratio of the 100-120 mesh granite stone powder accounts for 75%.

[0048] The preparation method of the phase change energy storage material is as follows:

[0049] S1. Treatment of diatomite: Soak 25.7g of diatomite in 0.1mol / L dilute KOH solution, wash it with water, calcinate at 1500°C for 5 hours in a muffle furnace, cool it, take it out, and grind it until 30-80 mesh, spare;

[...

Embodiment 3

[0054] Example 3 Imitation Granite Coating for Exterior Wall of Thermal Insulation Building

[0055] Raw material composition (parts by weight): 220 parts of water, 12 parts of sodium carboxymethylcellulose, 3 parts of anionic surface active dispersant, 320 parts of granite stone powder, 55 parts of quartz sand, 40 parts of phase change energy storage material, mineral oil defoaming 3 parts of agent, 22 parts of silicone acrylic emulsion, 12 parts of propylene glycol methyl ether acetate, 2 parts of 2,2-dibromo-cyanoacetamide.

[0056] The mesh number of the granite stone powder is 80-120 mesh, and the weight ratio of the 100-120 mesh granite stone powder accounts for 62%.

[0057] The preparation method of the phase change energy storage material is as follows:

[0058] S1. Treatment of diatomite: Soak 27.5g of diatomite in 0.04mol / L dilute barium hydroxide, wash it with water, and calcinate it in a muffle furnace at 1150°C for 3.5h, cool it, take it out, and grind it. Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com