Method for washing positive electrode material precursor

A cathode material and washing method technology, applied in chemical instruments and methods, battery electrodes, inorganic chemistry, etc., can solve the problems of wasting water, affecting the production cost of precursors, affecting the production cost of cathode materials, etc. The effect of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] The preparation method of the sulfonamido polypyrrole permeable membrane is:

[0068] 1) heating the sulfonamide polypyrrole and a solvent to obtain a sulfonamide polypyrrole solution;

[0069] 2) immersing the base film in a sulfonamide-based polypyrrole solution, and then drying;

[0070] 3) Repeat step 2) to obtain the diaphragm;

[0071] 4) drying the membrane after washing to obtain a sulfonamide-based polypyrrole permeable membrane;

[0072] Specifically, the sulfonamide polypyrrole and the solvent are stirred at room temperature for 5-10 hours, heated to 40-60° C. and kept for 5-10 hours to obtain a sulfonamide-polypyrrole solution for later use; the solvent is preferably N-methylpyrrolidone.

[0073] Immerse the base membrane of the permeable membrane in the above-mentioned sulfonamide-based polypyrrole solution, keep it for 20-30 minutes, take it out for vacuum drying, and then immerse it in the sulfonamide-based polypyrrole solution again after drying, repea...

Embodiment 1

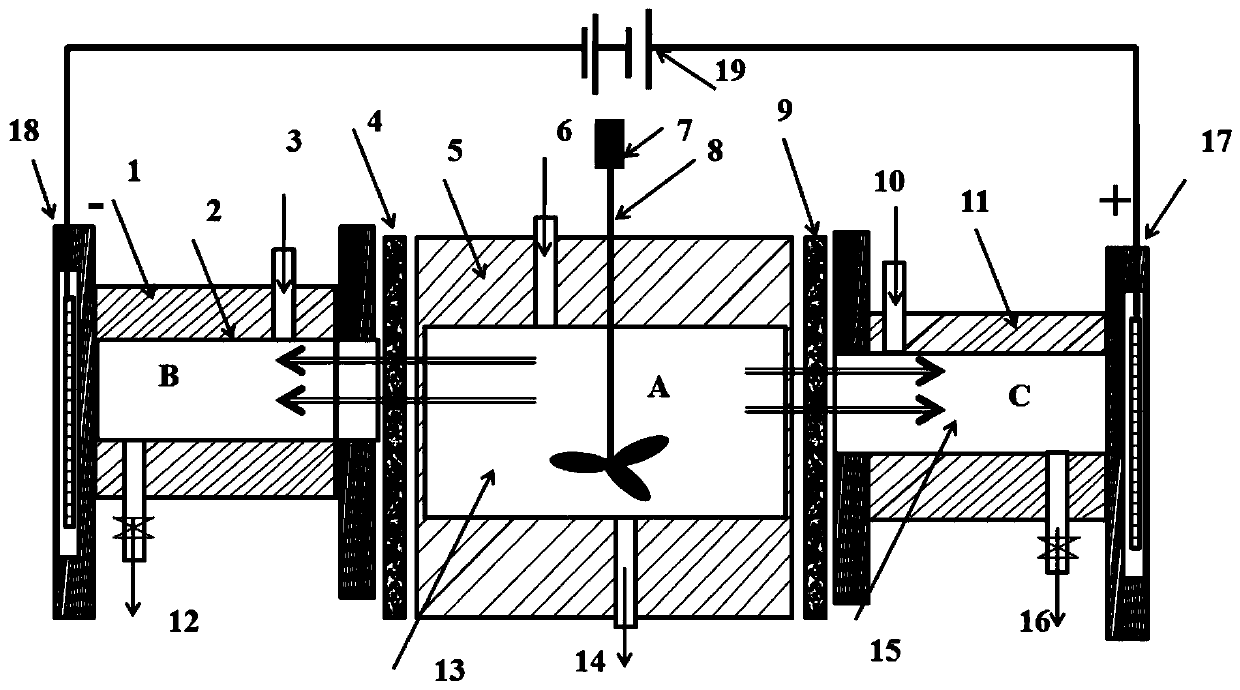

[0114] The present embodiment provides a kind of lithium-ion battery cathode material precursor cleaning device, see figure 1 , figure 1 A schematic diagram of a lithium-ion battery cathode material precursor washing device provided by the present invention, wherein, 1-PP tank; 2-cathode chamber; 3-water inlet; 4-cation selective permeable membrane; 5-PP Tank; 6-feeding port; 7-stirring motor; 8-stirring paddle; 9-anion selective permeable membrane; 10-feeding port; 11-PP tank; 12-feeding port; Outlet; 15-anode chamber; 16-outlet; 17-electrode+; 18-electrode; -19-power supply.

[0115] The lithium ion battery cathode material precursor washing method and device thereof provided in this embodiment include

[0116] The present invention provides a lithium ion battery cathode material precursor washing method and its device, comprising: a washing stirring tank including a water inlet, a feeding inlet, a stirring motor, and a stirring paddle;

[0117] The cathode chamber includ...

Embodiment 2

[0122] A method for washing a lithium ion battery cathode material precursor, comprising the following steps:

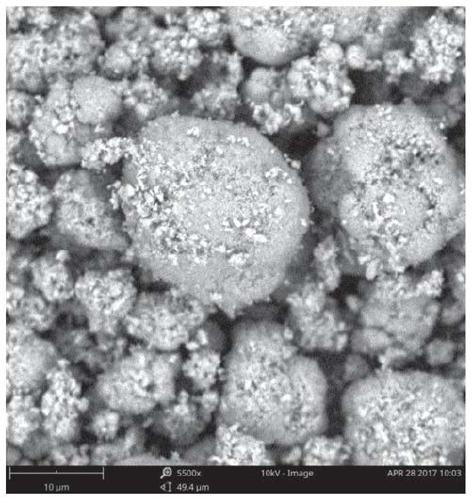

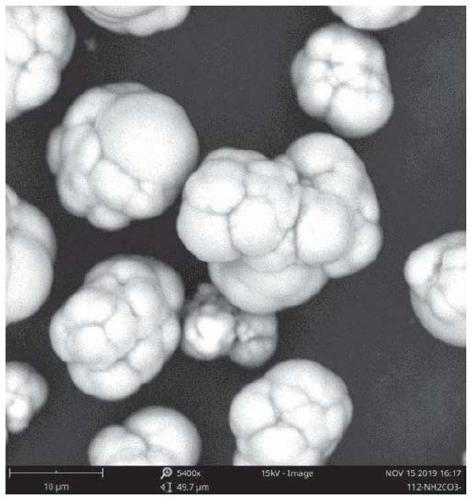

[0123] 1) Synthesize the cathode material precursor of lithium-ion battery by co-precipitation method, which is mainly Ni 0.5 co 0.2 mn 0.3 (OH) 2 ; It contains impurity ions as Na + and SO 4 2- , where the original sodium ion concentration of the precursor is 8000ppm

[0124] 2) Add 100 kg of precursor to the 250L washing tank, add 100L deionized water and stir;

[0125] 3) Control the temperature of the solid-liquid mixture in the washing tank at 45°C and the pH at about 10.5 and start stirring.

[0126] 4) With a voltage of about 2500V, under the action of an electric field, the impurity ions Na contained in the precursor + , SO 4 2- Respectively through the anion and cation sulfonamide-based polypyrrole permeable membrane and polyethersulfone permeable membrane to the cathode chamber B and anode chamber C enrichment,

[0127] 5) Discharge the impurity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com