Membrane and electrochemical device comprising same

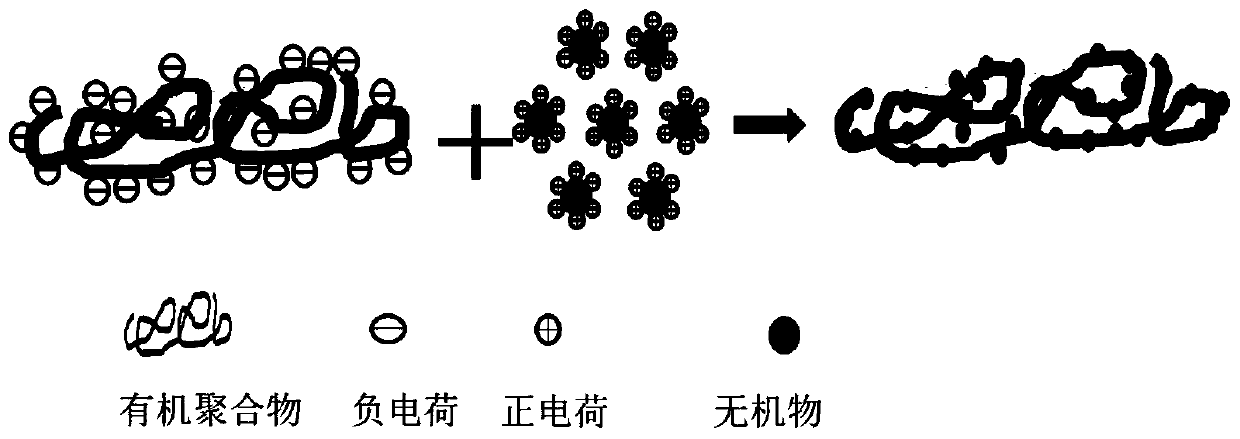

A diaphragm, electrostatic self-assembly technology, applied in electrochemical generators, circuits, electrical components, etc., can solve the problems of accelerating the flow rate of electrolyte, loss of energy, accelerating infiltration of electrolyte, etc., to improve cycle performance and energy density, The effect of prolonging the cycle life and shortening the rest time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

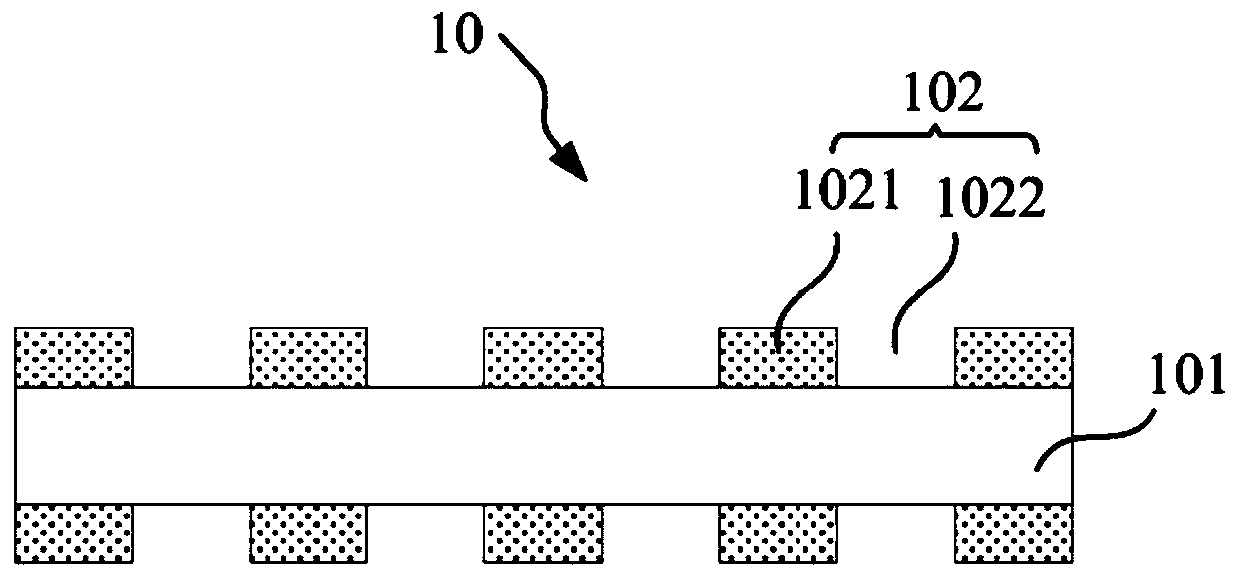

[0083] The process of positive electrode sheet, negative electrode sheet, electrolyte, cell forming and so on is as follows:

[0084] Preparation of positive electrode sheet: Add lithium cobaltate, conductive carbon, and binder polyvinylidene fluoride into nitrogen methyl pyrrolidone (NMP) at a mass ratio of 97:1.5:1.5 and mix evenly to make positive electrode slurry, and then coat, Compacting and slitting to make positive electrode sheets.

[0085] Preparation of the negative electrode sheet: add graphite, conductive carbon, thickener sodium carboxymethyl cellulose, and binder styrene-butadiene rubber into deionized water at a mass ratio of 97:0.8:0.7:1.5 and mix them uniformly to form a negative electrode slurry, and then After coating, compacting and slitting, the negative electrode sheet is made.

[0086] Preparation of non-aqueous electrolyte: LiPF6, ethylene carbonate (EC) and diethyl carbonate (DEC) are configured into a solution with a LiPF6 concentration of 1.0mol / L ...

Embodiment 2

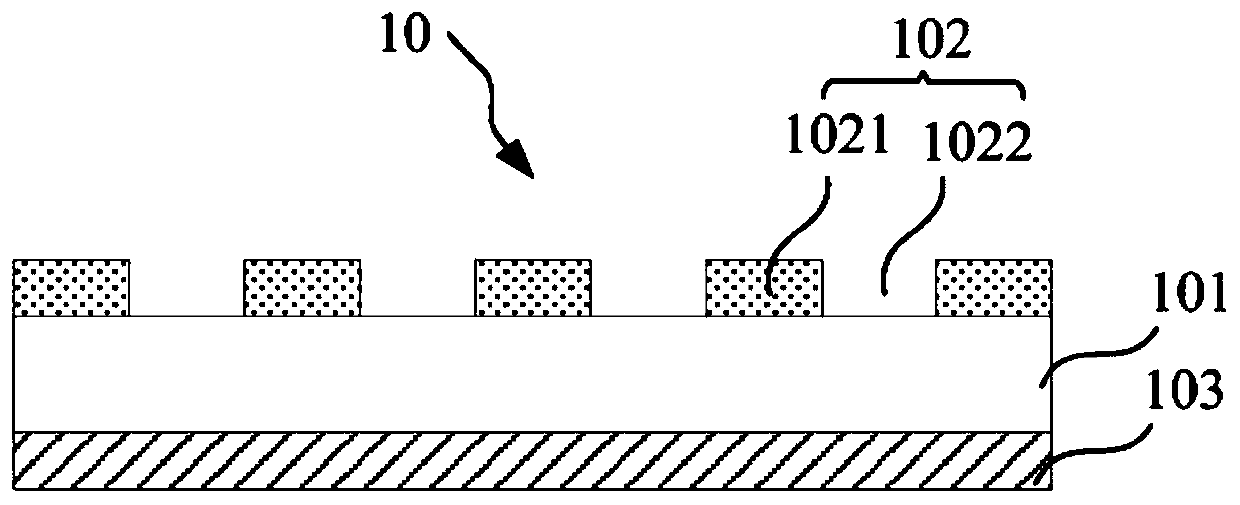

[0090] The processes of positive electrode sheet, negative electrode sheet, electrolyte solution, and cell molding are the same as in Example 1. The separator is as follows: the substrate is a 12 μm single-layer porous polyethylene substrate, and a discontinuous mixed coating with a thickness of 2 μm is provided on one side. A continuous mixed coating with a thickness of 2 μm is provided on one side, and the ceramic slurry in the coating film area includes the following mass components: 100 parts of polymethacrylic resin, lithium lanthanum titanium oxide Li x La 2 / 3-x TiO 3 (0﹤X﹤0.16) 5 parts, 100 parts of carbon disulfide, 0.5 part of sodium polystyrene sulfonate, 0.5 part of cetyltrimethylammonium bromide. Polymethacrylic acid resin was dispersed in carbon disulfide, and sodium polystyrene sulfonate was added to adjust the Zeta potential of the mixed system to below -30mV. lithium lanthanum titanyl Li x La 2 / 3-x TiO 3 (0﹤X﹤0.16) is dispersed in carbon disulfide, and the...

Embodiment 3

[0092] The processes of positive electrode sheet, negative electrode sheet, electrolyte solution, and cell molding are the same as in Example 1. The separator is as follows: the substrate is a 12um single-layer porous polypropylene substrate, and a continuous mixed coating with a thickness of 2μm is provided on both sides. One side of the coating is further provided with a discontinuous mixed coating with a thickness of 2 μm. The mixed coating ceramic slurry includes the following mass components: 100 parts of polyolefin, 5 parts of lithium aluminum oxide, 100 parts of acetone, poly 0.5 part of sodium styrene sulfonate, 0.2 part of cetyltrimethylammonium bromide. Polyolefin was dispersed in acetone, and sodium polystyrene sulfonate was added to adjust the Zeta potential of the mixed system to below -30mV. Lithium aluminum oxide was dispersed in acetone, and a cationic surfactant, cetyltrimethylammonium bromide, was added to adjust the Zeta potential of the mixed system to abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com