High-performance hole transport material and preparation method and application thereof

A hole transport material, high-performance technology, applied in the field of organic small molecule optoelectronic materials, can solve the problems of not meeting the requirements of thermal stability and film-forming properties of materials, affecting the life of OLEDs, low glass transition temperature, etc. The effect of enhanced morphology stability, improved film morphology stability, and increased glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

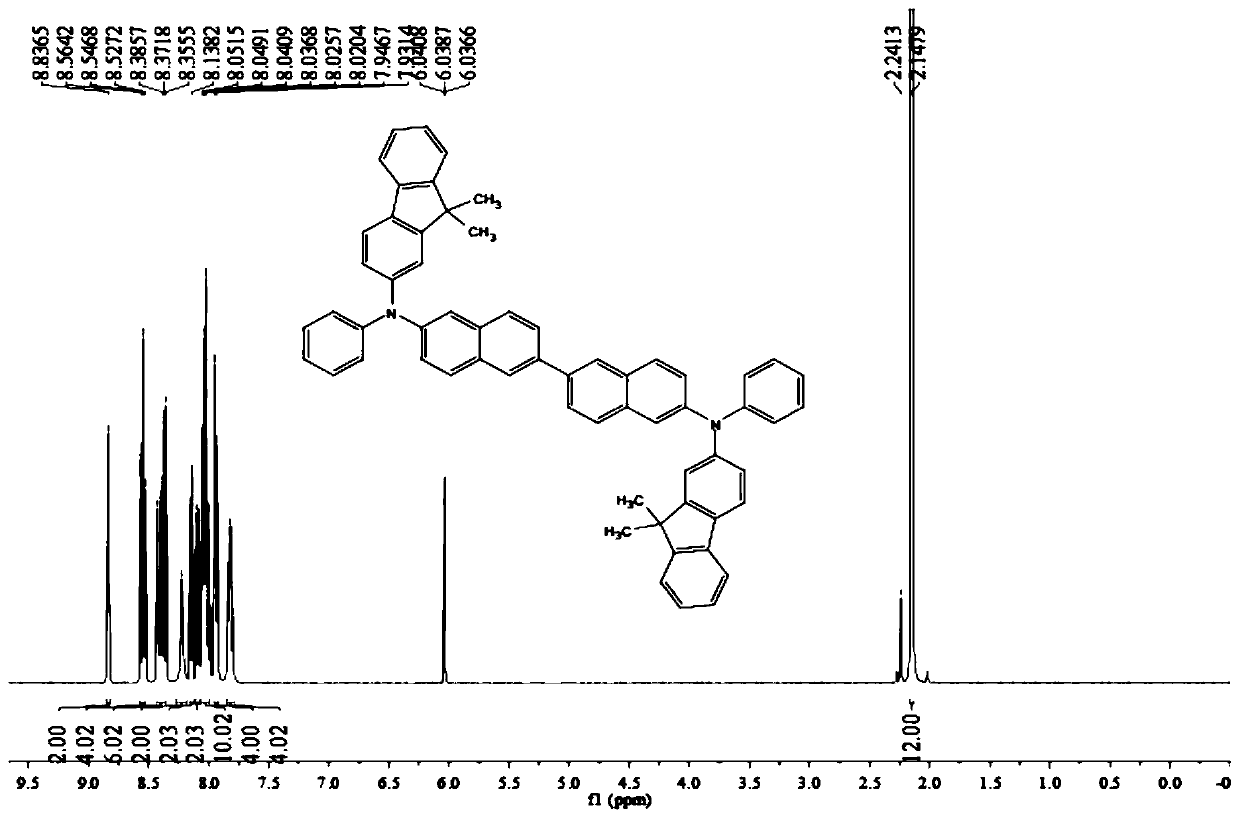

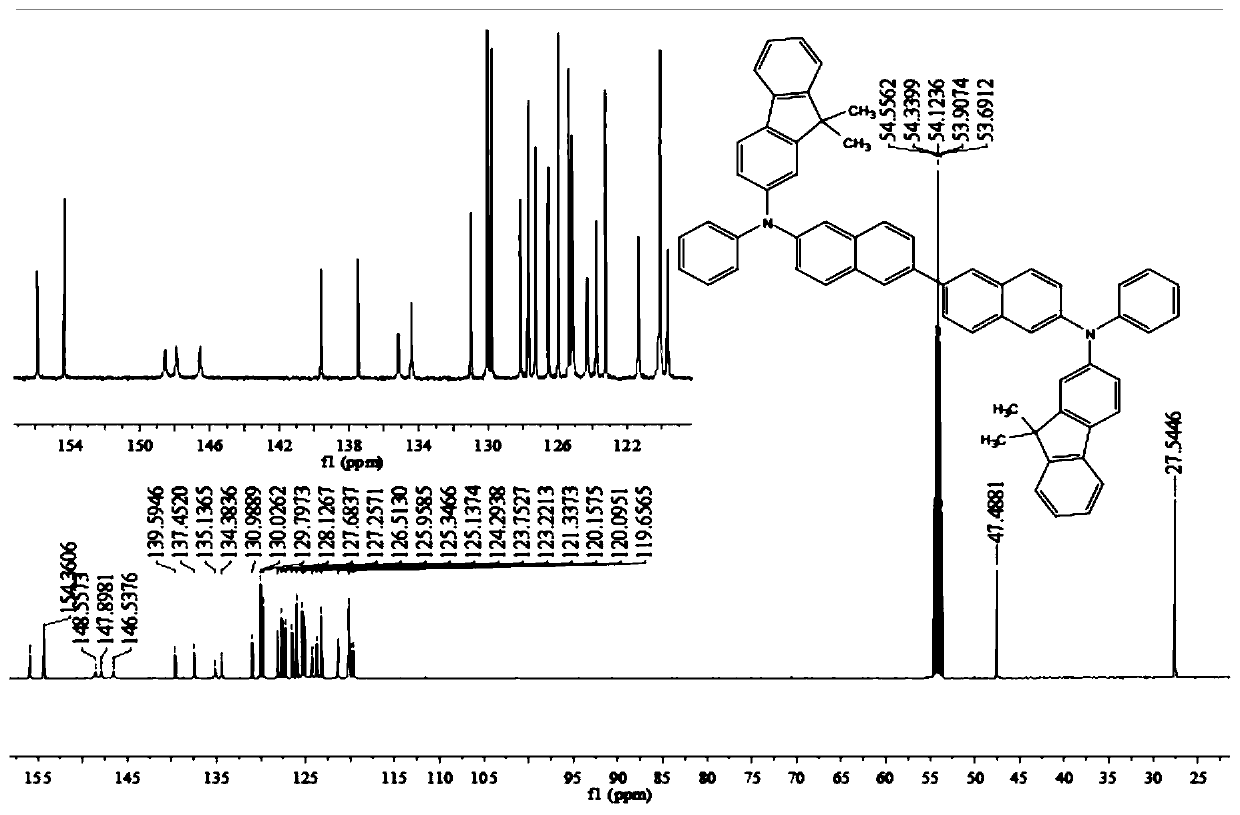

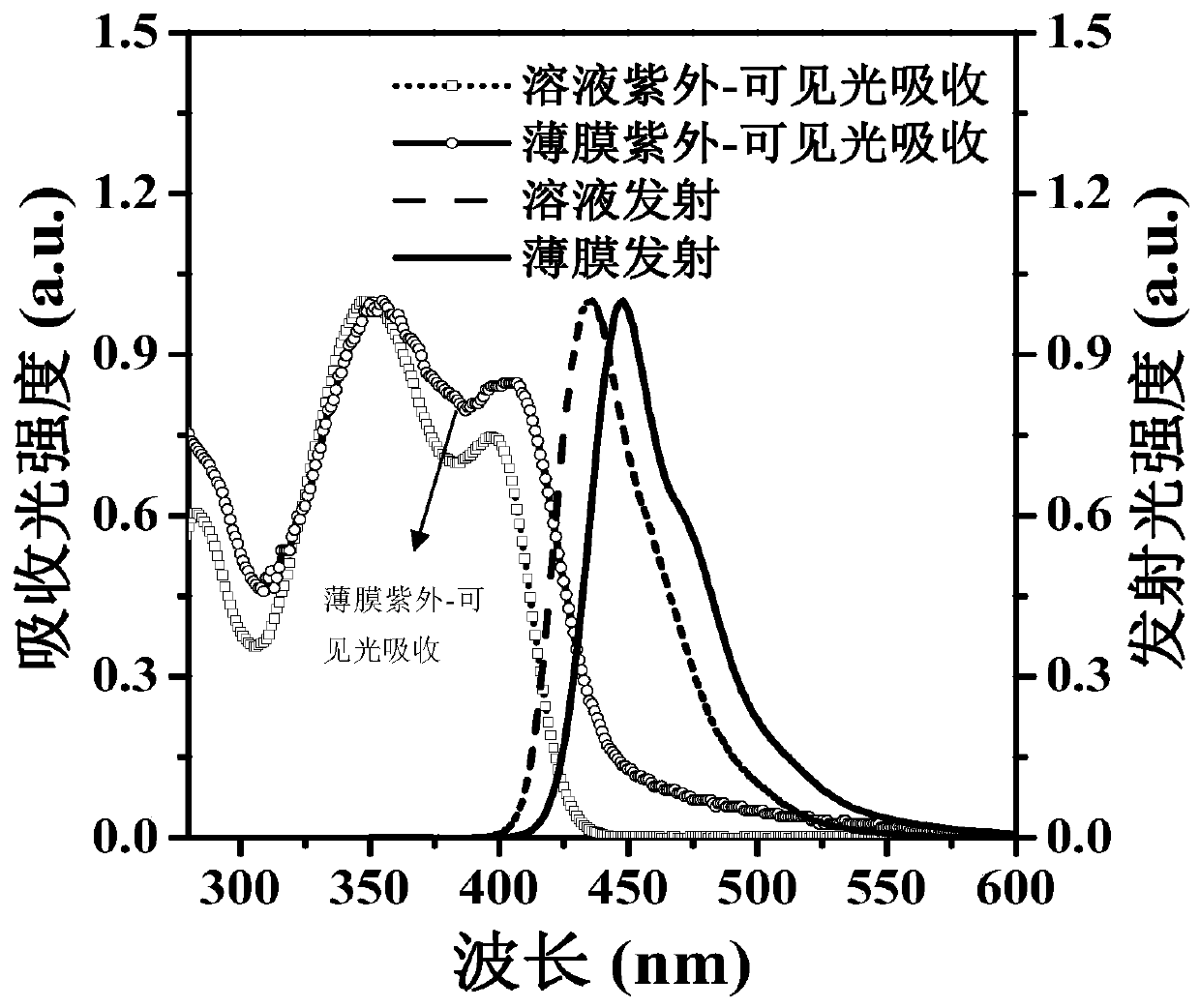

[0056] The structural formula of the small organic molecule hole transport material of the present embodiment is specifically as follows:

[0057]

[0058] The preparation method of the hole transport material A-1 with a high glass transition temperature in this embodiment comprises the following steps:

[0059] Step 1: Preparation of 6-bromo-N-phenyl-2-naphthylamine (compound II), reaction equation:

[0060]

[0061] P-toluenesulfonic acid (1.7g, 9mmol), aniline (12.6g, 0.135mol) and 6-bromo-2-naphthol (10.0g, 0.045mol) were dissolved in 10ml of p-xylene, heated to React at 190°C for 7 hours, then lower the temperature to 70°C, add an appropriate amount of sodium acetate (just to make the reaction system alkaline) and 100ml of ethanol and continue stirring for 10 minutes, then distill the reaction solution under reduced pressure to remove the solvent, then add warm water to stir, Suction filtration was then carried out, and the filter cake was reflux washed with ethano...

Embodiment 2

[0088] The structural formula of the small organic molecule hole transport material of the present embodiment is as follows:

[0089]

[0090] The preparation method of the small organic molecule hole transport material A-2 of this embodiment:

[0091] Step 1: Preparation of 6-bromo-N-phenyl-2-naphthylamine (II), reaction equation:

[0092]

[0093] Step (1) is exactly the same as step (1) in embodiment 1, no longer repeat them;

[0094] Step 2: Preparation of N-(6-bromonaphthalene-2-yl)-9-methyl-N-phenyl-9H-carbazol-3-amine (5), reaction equation:

[0095]

[0096] The difference between the operation process of step (2) and step (2) of embodiment 1 is that one of the reactants 2-iodo-9,9-dimethyl-9H-fluorene of step (2) in embodiment 1 uses 3 -Iodine-9-methyl-9H-carbazole instead, the column chromatography separation developer initially uses petroleum ether, after the unreacted 3-iodo-9-methyl-9H-carbazole is removed, the developer Change to a mixed solvent of pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com