Copper sheet embedded soft magnetic powder core inductor as well as preparation method and application thereof

A soft magnetic powder core and embedded technology, applied in the field of electronics, can solve the problems of difficult to obtain high magnetic permeability, low saturation magnetic flux density, and difficult to achieve inductance, etc., to achieve large-scale automated production, high density And the saturation magnetic flux density, the effect of increasing the magnetic permeability and inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

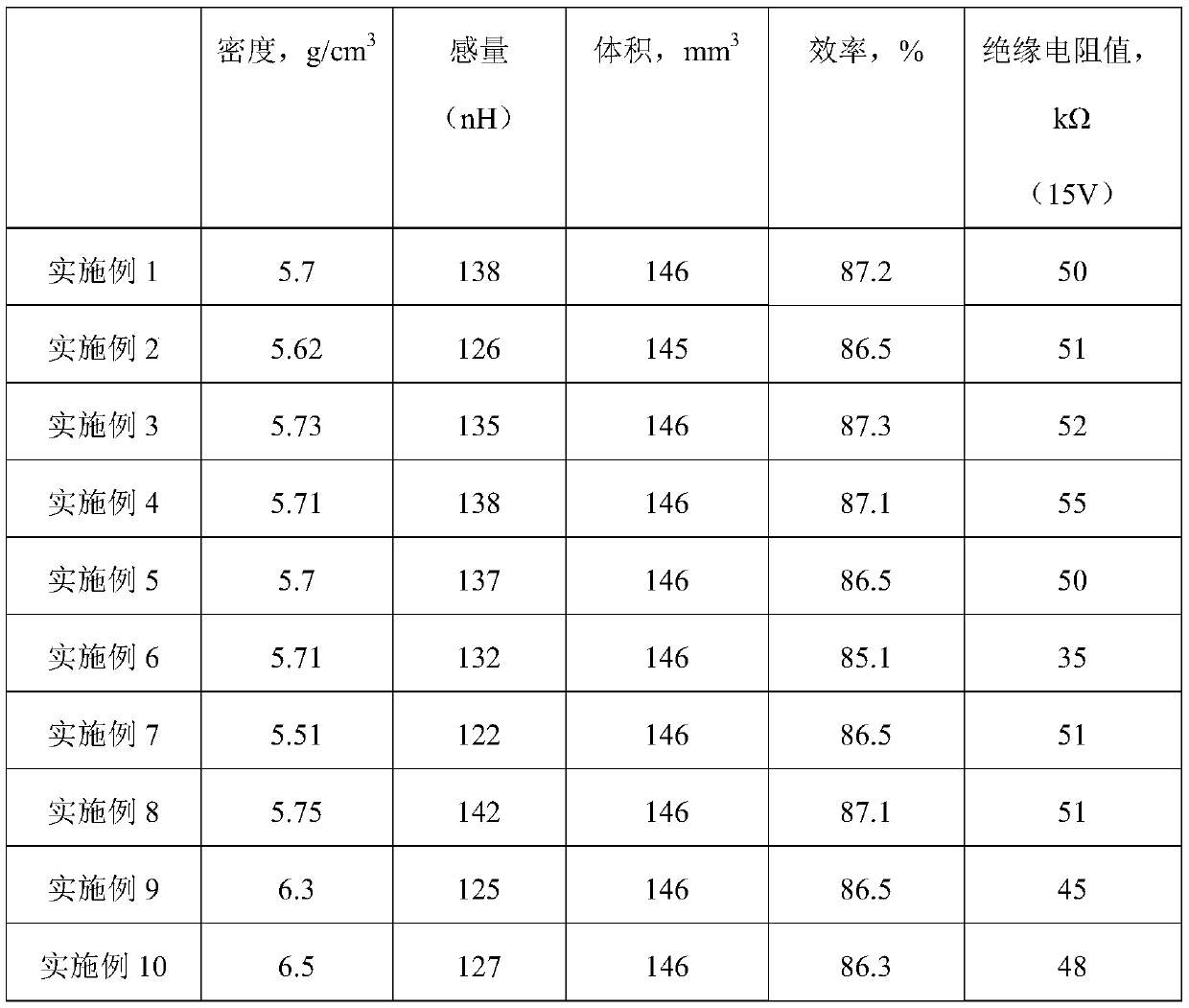

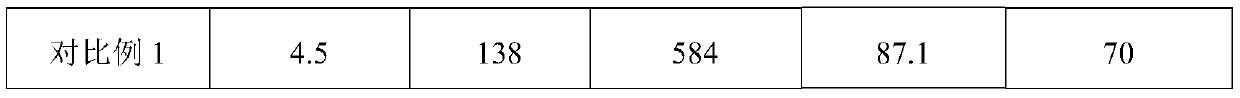

Examples

Embodiment 1

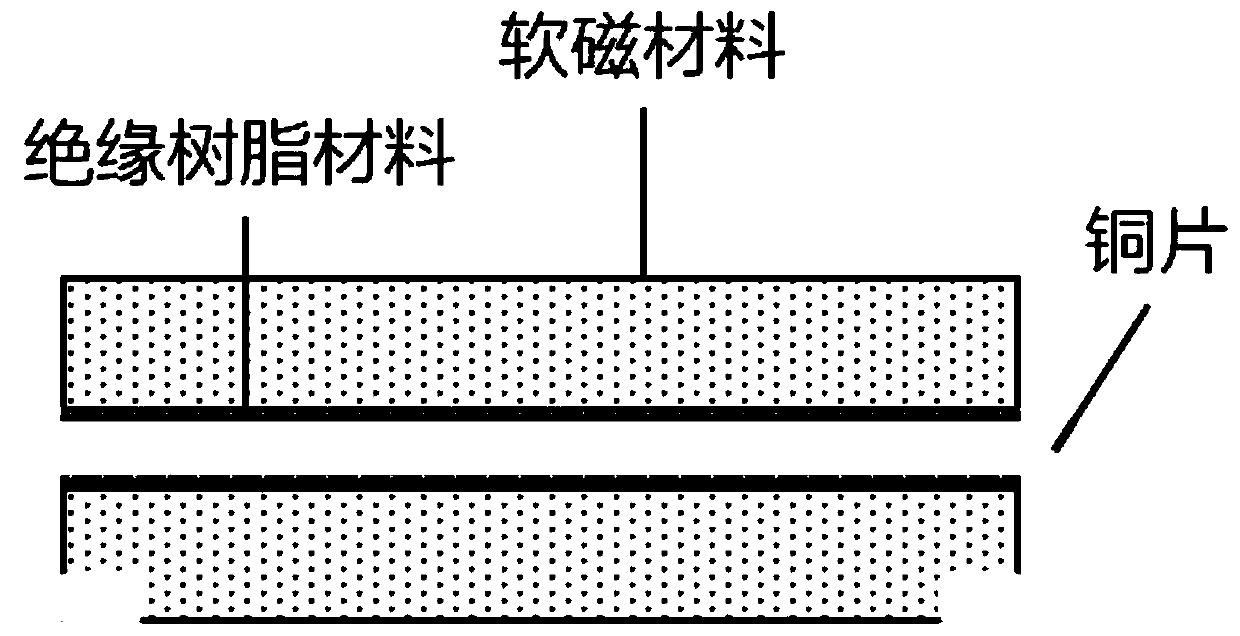

[0048] Preparation method of copper sheet embedded soft magnetic powder core inductor:

[0049] (1) Silicone resin REN 60 is evenly coated on the surface of copper sheet with a thickness of 0.3mm and a width of 2.5mm, and baked until it is cured;

[0050] (2) Embed the copper sheet treated in step (1) in the sendust magnetic powder, the average particle size of the powder is 15 μm, and the 2 Press molding to obtain a formed body, the formed body is 14 mm long, 5 mm wide, and 2 mm high; after that, the formed body is placed in an annealing furnace, and annealed at 680 ° C for 120 minutes in a nitrogen atmosphere to obtain a copper sheet embedded soft Powder core inductors.

[0051] The size of the molded body includes the size of the soft magnetic material and the size of the copper sheet inside the soft magnetic material.

Embodiment 2

[0053] Preparation method of copper sheet embedded soft magnetic powder core inductor:

[0054] (1) Silicone resin REN 60 is evenly coated on the surface of copper sheet with a thickness of 0.25mm and a width of 2.5mm, and baked until it is cured;

[0055] (2) Embed the copper sheet treated in step (1) in the sendust magnetic powder, the average particle size of the powder is 15 μm, and the 2 Press molding to obtain a formed body, the formed body is 14 mm long, 5 mm wide, and 2 mm high; after that, the formed body is placed in an annealing furnace, and annealed at 680 ° C for 120 minutes in a nitrogen atmosphere to obtain a copper sheet embedded soft Powder core inductors.

Embodiment 3

[0057] Preparation method of copper sheet embedded soft magnetic powder core inductor:

[0058] (1) Silicone resin REN 60 is evenly coated on the surface of copper sheet with a thickness of 0.3mm and a width of 2.7mm, and baked until it is cured;

[0059] (2) Embed the copper sheet treated in step (1) in the sendust magnetic powder, the average particle size of the powder is 10 μm, and the 2 Press molding to obtain a formed body, the formed body is 14 mm long, 5 mm wide, and 2 mm high; after that, the formed body is placed in an annealing furnace, and annealed at 680 ° C for 120 minutes in a nitrogen atmosphere to obtain a copper sheet embedded soft Powder core inductors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com