Peel-off mask composition and preparation method thereof

A composition and peel-off technology, which is applied in the direction of pharmaceutical formulations, cosmetic preparations, dressing preparations, etc., can solve the problems of difficulty in forming a peelable film and skin irritation, and achieve good appearance and improved peelability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, preparation of modified lac resin

[0027] Mix shellac resin and absolute ethanol at a weight ratio of 1:10, slowly drop into octenyl succinic anhydride, react in a water bath at 35°C for 1 hour, and maintain the reaction with 0.1mol / L aqueous sodium hydroxide solution during the entire reaction process The pH value of the system is 8.0-8.5. After the reaction, the reactant is centrifuged and washed three times with 70% ethanol solution, and dried to obtain the modified shellac resin.

Embodiment 2~4

[0028] Embodiment 2~4, peel-off facial mask composition (mass fraction)

[0029] components Example 2 Example 3 Example 4 Titanium dioxide 5.0% 8.0% 10.0% talcum powder 5.0% 12.0% 10.0% Modified Shellac Resin 3.2% 4.0% 1.8% Polyvinylpyrrolidone 4.0% 4.0% 3.0% glycerin 10.0% 6.0% 12.0% olive oil 3.0% 2.5% 4.0% squalane 2.0% 2.5% 2.0% Hydrolyzed Oat Protein 4.0% 5.0% 5.0% Nonapeptide-1 4.0% 5.0% 3.0% Tremella Extract 4.0% 5.0% 5.0% ethanol 8.0% 6.0% 10.0% essence 0.1% 0.1% 0.1% parabens 0.2% 0.2% 0.2% Deionized water add up to 100% add up to 100% add up to 100%

[0030] Preparation:

[0031] Dissolve titanium dioxide and talcum powder in deionized water in mixing tank A, add glycerin, hydrolyzed oat protein, nonapeptide-1 and white fungus extract, heat to 80°C and stir evenly to form a water phase; mix ethanol, polyvinylpyrrolidone, Mix modified s...

experiment example 1

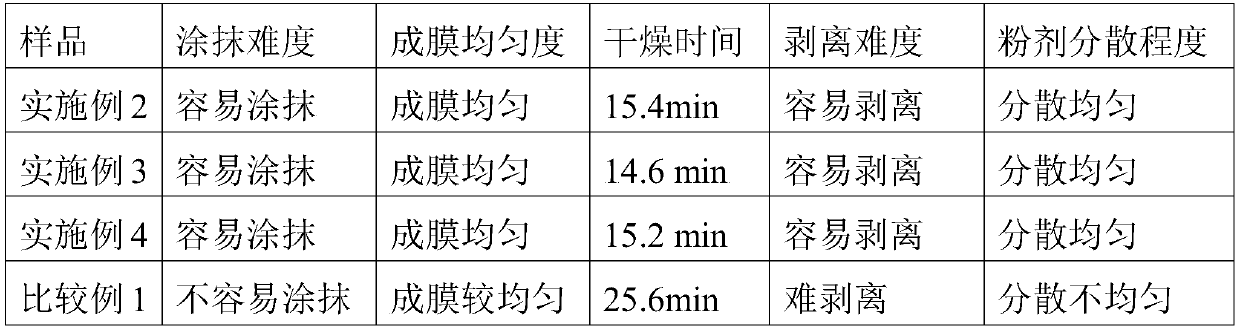

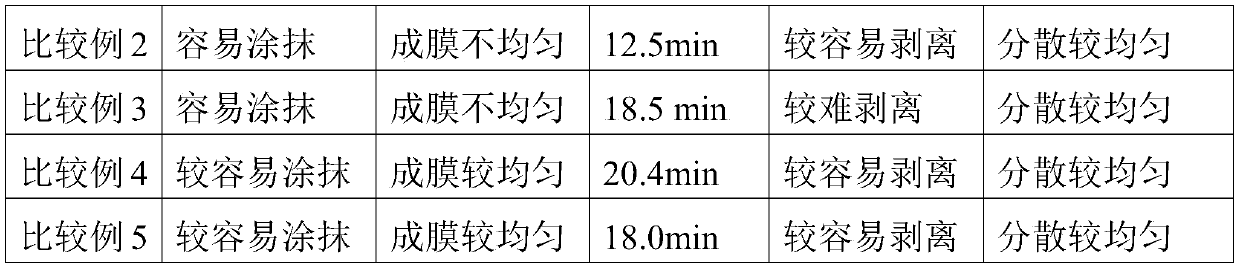

[0042] Experimental example 1, sensory evaluation

[0043] Select 80 volunteer subjects to carry out skin test, divide into 8 groups at random, each group has 10 people (age 23~40 years old), take embodiment 2~4 and comparative example 1~5 described facial mask composition as test sample After washing the face, each subject took an appropriate amount of sample and applied it on the facial skin, and took it off after it was completely dry. Difficulty and degree of dispersion of powder particles were evaluated, and the evaluation results are shown in Table 1 below.

[0044] Table 1 Sensory evaluation results

[0045]

[0046]

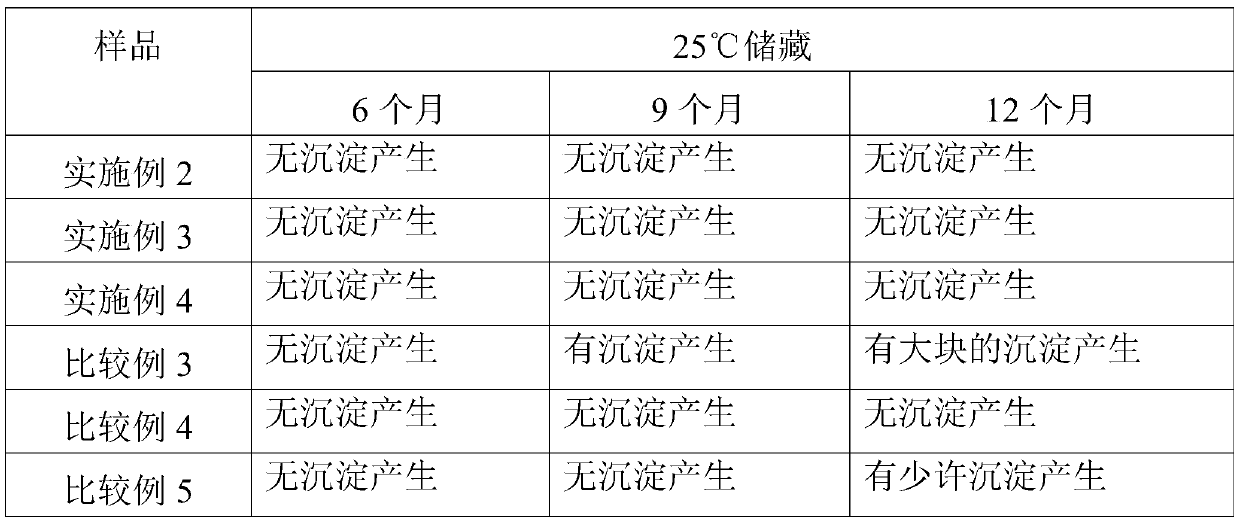

[0047] It can be seen from the above table that the facial mask compositions of Examples 2-4 of the present invention have the advantages of easy application, uniform film formation, easy peeling, and uniform powder dispersion, and an easily peelable film can be formed after 14.6-15.4 minutes of coating. And if only adopt polyvinylpyrrolidone as fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com