Construction method of recombinant clostridium acetobutylicum and application of recombinant clostridium acetobutylicum in preparation of butanol by fermenting hemicellulose

A Clostridium acetobutylicum and construction method technology, applied in the construction of recombinant Clostridium acetobutylicum, and the application field of fermenting hemifiber to prepare butanol, can solve the problem that renewable biomass hemicellulose is difficult to directly degrade and utilize, Problems such as high production cost and complex process conditions can achieve the effect of reducing the loss of bioenergy, saving costs and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1: Construction of xylanase gene recombinant expression plasmid

[0056] (1) Use the Bacterial Genome Extraction Kit (TaKaRa Code: DV810A) to extract the genomic DNA of Clostridium butyricum C. acetobutyicum B3 in the middle and late stages of logarithmic growth;

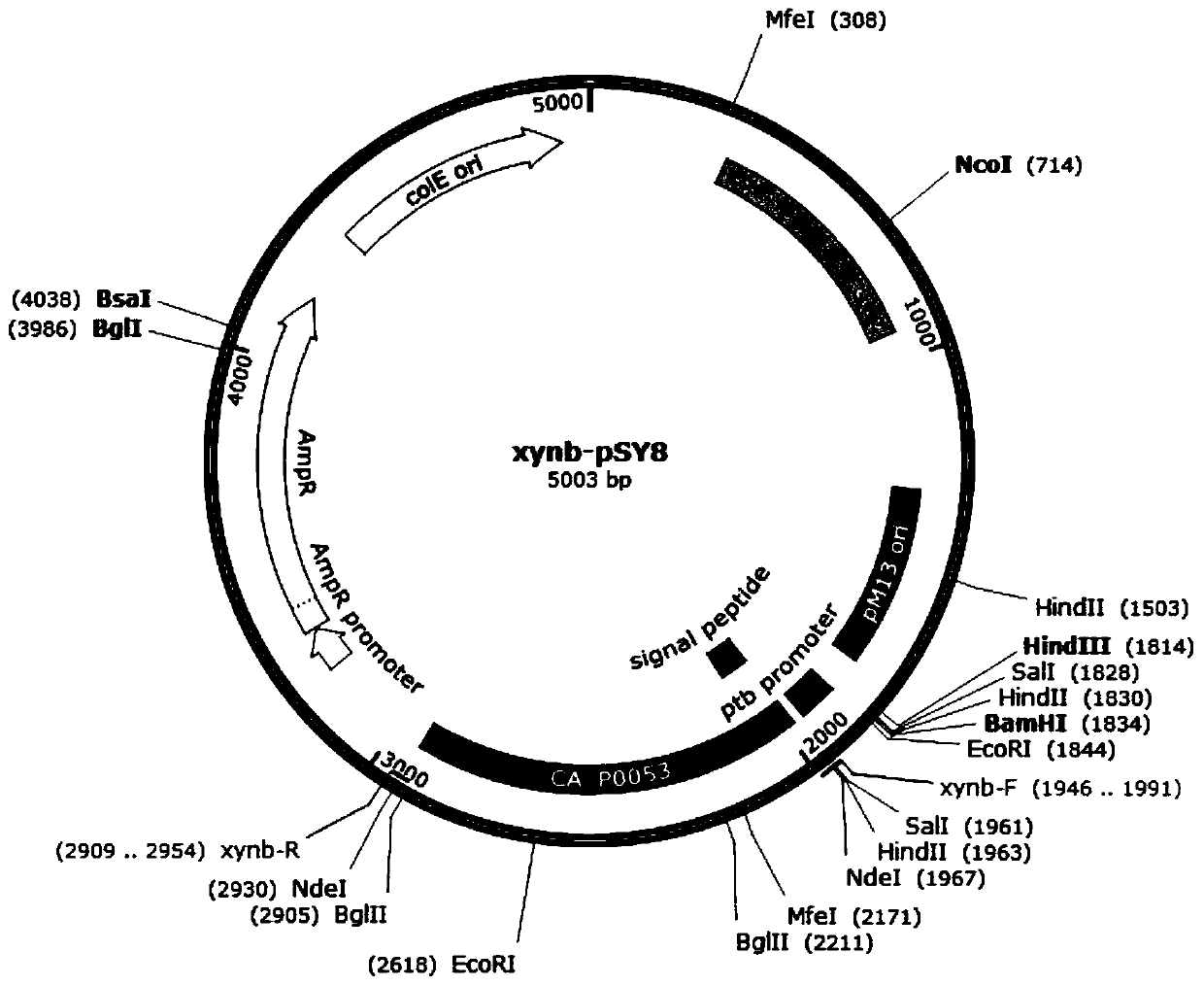

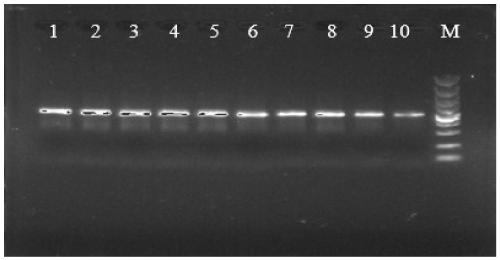

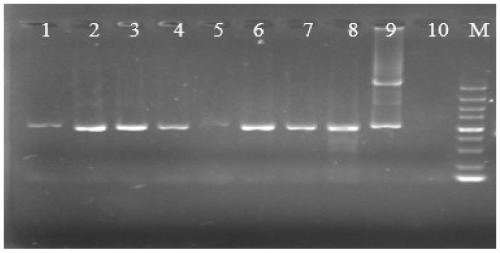

[0057] (2) According to the instructions of the ClonExpress II One Step Cloning Kit kit, design reasonable PCR amplification primers, the sequences of which are shown in Table 5, where F represents the forward primer and R represents the reverse primer. Using the genomic DNA extracted in step (1) as a template, the xylanase CA_P0053 gene (NCBI-GeneID: 1116058) fragment was obtained by PCR amplification, the nucleotide sequence of which was shown in SEQ ID NO.1, The constructed plasmid map is as follows figure 1 Shown; After xylanase gene CA_P0053 gene fragment PCR amplification, PCR product nucleic acid gel electrophoresis result is as follows figure 2 shown;

[0058] (3) Use TaKaRa MiniBEST Ag...

Embodiment 2

[0069] Embodiment 2: the construction of recombinant Clostridium acetobutylicum

[0070] (1) Under anaerobic conditions, culture in 2×YTG medium until mid-log phase (OD 600 =1.1) of C.acetobutylicum B3 (preserved with the General Microbiology Center of China Committee for Culture Collection of Microorganisms, CGMCC5234; the information of the strain is disclosed in detail in the Chinese patent application number 201210075094.X) culture solution 60mL.

[0071] (2) Discard the supernatant after centrifuging at 5000rpm for 10min at 4°C, add an appropriate amount of pre-cooled electroporation buffer EPB (270mM sucrose, 5mM phosphate buffer, pH 7.4), wash twice, and reconstitute with 2.3mL EPB. hanging.

[0072] (3) Then take 570 μL of the resuspended bacterial solution described in step (1), add it to a 4 mm electroporation cup and place it in an ice bath to cool, and add 20 μL of the methylated plasmid constructed in Example 1, and place it on ice for 2 minutes. 2.0kV voltage, ...

Embodiment 3

[0075] Example 3: Recombinant strains can efficiently secrete and express xylanase

[0076] (1) Take 200 uL each of the genetically engineered bacterial strain C.acetobutylicum B3-0053 preserved in Example 2 and its corresponding wild-type bacterial strain C.acetobutylicum B3, and apply it to P2 solid plate medium (containing 20 μg / L formazan sulfone chloramphenicol), placed in an anaerobic box at 37°C, and the incubation time was 24h.

[0077] (2) Transfer the plate-cultured bacteria to P2 liquid medium (containing 20 μg / L thiamphenicol chloramphenicol), and culture statically at 37°C until OD 600 = 2.2;

[0078] (3) Transfer the seed culture medium described in step (2) to the secondary P2 seed culture medium at an inoculum size of 10%, and collect the treatment samples after static cultivation in a 30° C. incubator for 36 hours;

[0079] (4) Centrifuge the collected sample described in step (3) at 4° C. at 8000 rpm to collect the supernatant and precipitate, the collected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com