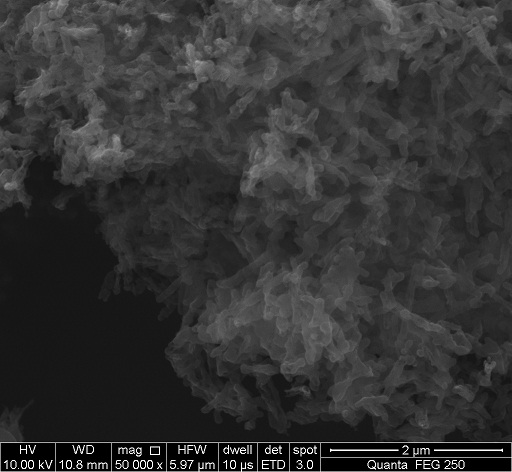

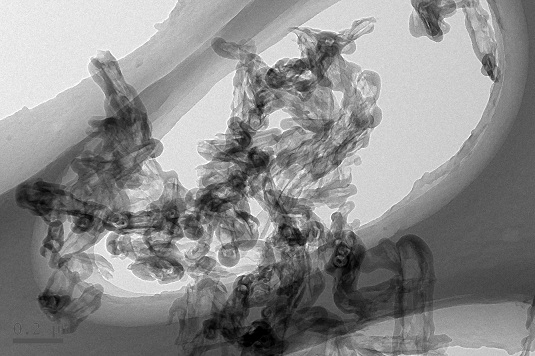

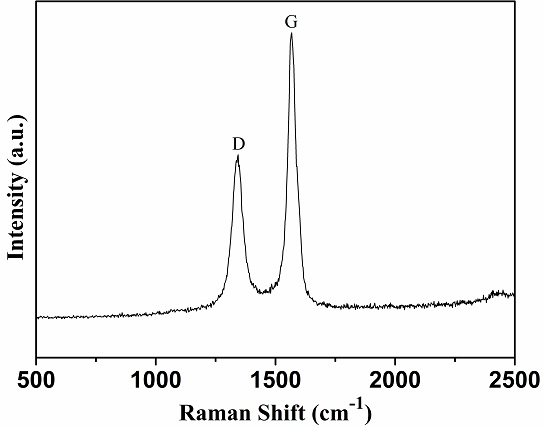

A highly graphitized boron-doped carbon nanocapsule and its preparation method

A technology of nanocapsules and high-temperature graphitization, which is applied in the field of nanomaterials, can solve expensive problems, achieve low cost, promote vigorous development, and have important practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of highly graphitized boron-doped carbon nanocapsules, the steps are as follows:

[0038] Accurately weigh 0.8 g of halloysite and 8 g of glucose, add alcohol (the mass fraction of alcohol is 99.5%) and 160 mL of water in a volume ratio of 1:1, put it into a beaker and sonicate for 30 minutes, then stir on a magnetic stirrer for 2 hours , and then put it into a 200 mL hydrothermal reactor, and hydrothermally heated it for 8 hours at 180 °C. The obtained hydrothermal product was filtered and washed with a mixture of water and alcohol with a volume ratio of 5:1, and then was placed in a vacuum drying oven for drying at 50° C. for 24 hours. The obtained dried product was placed in a 1:1 volume ratio of 15% HF and H 2 SO 4 Soak in the mixture for 24 hours, then filter and wash until the filtrate is neutral, and put the obtained product into a vacuum drying box to dry at 60°C for 24 hours. Then, take 2 g of the dried product, add 4.143 g of boric acid...

Embodiment 2

[0046] A preparation method of highly graphitized boron-doped carbon nanocapsules, the steps are as follows:

[0047] Accurately weigh 0.8 g of halloysite and 8 g of glucose, add alcohol (the mass fraction of alcohol is 99.5%) and 160 mL of water in a volume ratio of 1:1, put them in a beaker and sonicate for 20 minutes, and then stir on a magnetic stirrer for 1 hour. , and then put it into a 200mL hydrothermal reactor, and hydrothermally heated it for 6h at 160°C. The obtained hydrothermal product was filtered and washed with a mixture of water and alcohol with a volume ratio of 5:1, and then was placed in a vacuum drying oven for drying at 50° C. for 24 hours. The obtained dried product was placed in a 1:1 volume ratio of 25% HF and H 2 SO 4 Soak in the mixture for 12h, then filter and wash until the filtrate is neutral, and put the obtained product into a vacuum drying box to dry at 50°C for 24h. Then, take 2 g of the dried product, add 2 g of boric acid, mix it evenly, ...

Embodiment 3

[0049] A preparation method of highly graphitized boron-doped carbon nanocapsules, the steps are as follows:

[0050] Accurately weigh 0.8 g of halloysite and 12 g of glucose, add alcohol (the mass fraction of alcohol is 99.5%) and 170 mL of water in a volume ratio of 1:1, put them in a beaker and sonicate for 40 minutes, and then stir on a magnetic stirrer for 2 hours , and then put it into a 200 mL hydrothermal reactor, and hydrothermally heated it for 8 hours at 180 °C. The obtained hydrothermal product was filtered and washed with a mixture of water and alcohol with a volume ratio of 5:1, and then was placed in a vacuum drying oven for drying at 60° C. for 24 hours. The obtained dried product was placed in a volume ratio of 1:1 with 10% HF and H 2 SO 4 Soak in the mixture for 24 hours, then filter and wash until the filtrate is neutral, and put the obtained product into a vacuum drying box to dry at 60°C for 24 hours. Then, take 2 g of the dried product, add 8 g of bori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| degree of graphitization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com