Dilute sulfuric acid and graphene oxide co-doped modified titanium dioxide composite material and preparation method and application thereof

A composite material and titanium dioxide technology, applied in catalyst activation/preparation, alkali metal oxides/hydroxides, chemical instruments and methods, etc., can solve problems such as high ecological risk, water pollution, and insignificant antibiotic effect, and achieve high efficiency Photocatalytic removal, high-efficiency adsorption removal, and high-efficiency impurity removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

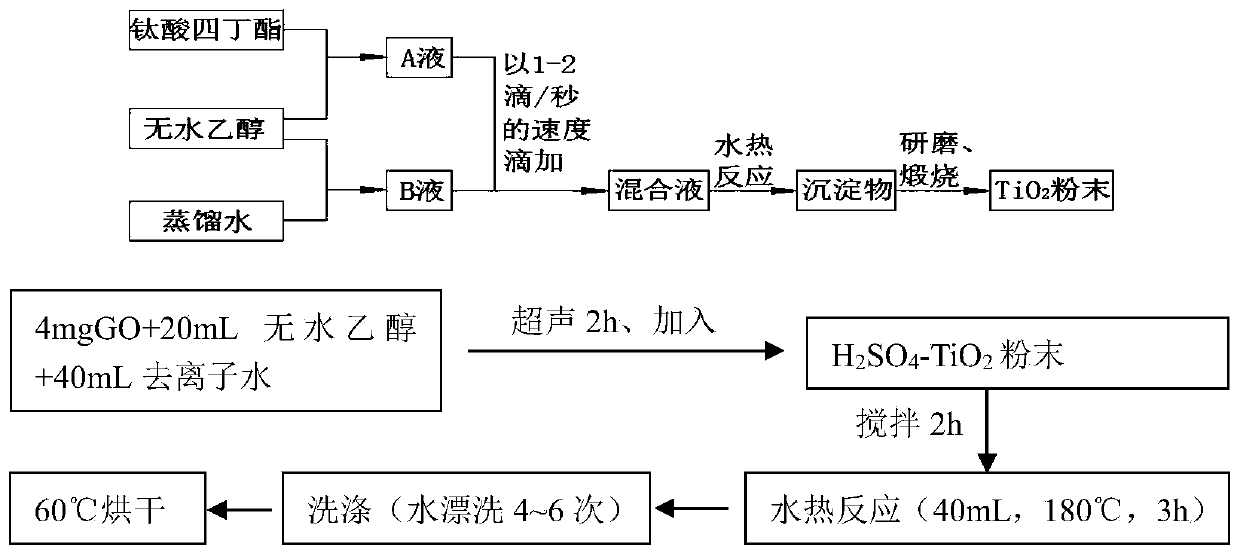

[0040] A preparation method of dilute sulfuric acid and graphene oxide co-doped modified titanium dioxide composite material, comprising the following steps:

[0041] (1) adding tetrabutyl titanate to ethanol to form liquid A;

[0042] (2) Prepare ethanol-sulfuric acid solution, which is added dropwise to liquid A and stirred to obtain a mixed solution;

[0043] (3) The mixed solution is reacted at a constant temperature, and cooled to obtain a slurry after the reaction is complete;

[0044] (4) centrifuging the slurry to obtain a precipitate, washing, drying, and grinding to obtain a powder;

[0045] (5) Obtain sulfuric acid-titanium dioxide composite material after the powder is calcined;

[0046] (6) prepare graphene oxide dispersion liquid;

[0047] (7) adding the sulfuric acid-titanium dioxide composite material to the graphene dispersion and stirring to react to form a suspension;

[0048] (8) After the suspension is reacted at a constant temperature, a crude product...

Embodiment 1

[0060] This embodiment is the preparation of a dilute sulfuric acid modified titanium dioxide composite material and pure titanium dioxide, as follows:

[0061] 1. Preparation of SO 4 2- TiO 2 :

[0062] (1) Take 10mL of tetrabutyl titanate and add 20mL of absolute ethanol to form A liquid (note the order of addition, if tetrabutyl titanate is poured into absolute ethanol, a large amount of white precipitate will be produced);

[0063] (2) Measure 10 mL of absolute ethanol and 10 mL of distilled water to form liquid B; drop liquid B into the stirred liquid A, and stir for 0.5 h to obtain a mixed liquid;

[0064] (3) Transfer the mixed solution to a reaction kettle, keep it in a constant temperature oven at 180°C for 5 hours, and cool naturally to obtain a slurry;

[0065] (4) The slurry is centrifugally cleaned with a high-speed centrifuge, washed 2-3 times with alcohol, and washed with distilled water until neutral, then the precipitate is dried in an oven at 60° C., and ...

Embodiment 2

[0079] Determination of test conditions

[0080] 1. Determination of initial concentration of tetracycline hydrochloride

[0081] This embodiment is the SO prepared in Example 1 4 2- / TiO 2 The test of the effect of the powder on the initial concentration of tetracycline hydrochloride on the adsorption performance, the specific steps are as follows:

[0082] Weigh 50mg of tetracycline hydrochloride and configure it into 1L solution, dilute to 10mg / L, 15mg / L, 20mg / L, 25mg / L, 30mg / L, 35mg / L, 40mg / L in proportion, add 50mg of material (pure TiO 2 , SO 4 2- / TiO 2 ), then carry out the light-dark reaction in a vibrating shaker with a constant temperature T=30°C and a shaking rate V=150rpm in the dark, and shake the adsorption to equilibrium. Take the supernatant, centrifuge, and measure the absorbance value of the solution.

[0083] Test results such as Figure 4 shown. The results show that under the action of different catalysts, the removal rate of tetracycline hydroc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com