Preparation method of high-purity potassium stannate

A potassium stannate, high-purity technology, applied in chemical instruments and methods, tin compounds, inorganic chemistry, etc., can solve the problems of high equipment, long process, nitrogen oxide emission, etc., achieve high economic and environmental benefits, metal recovery High rate, no three wastes discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

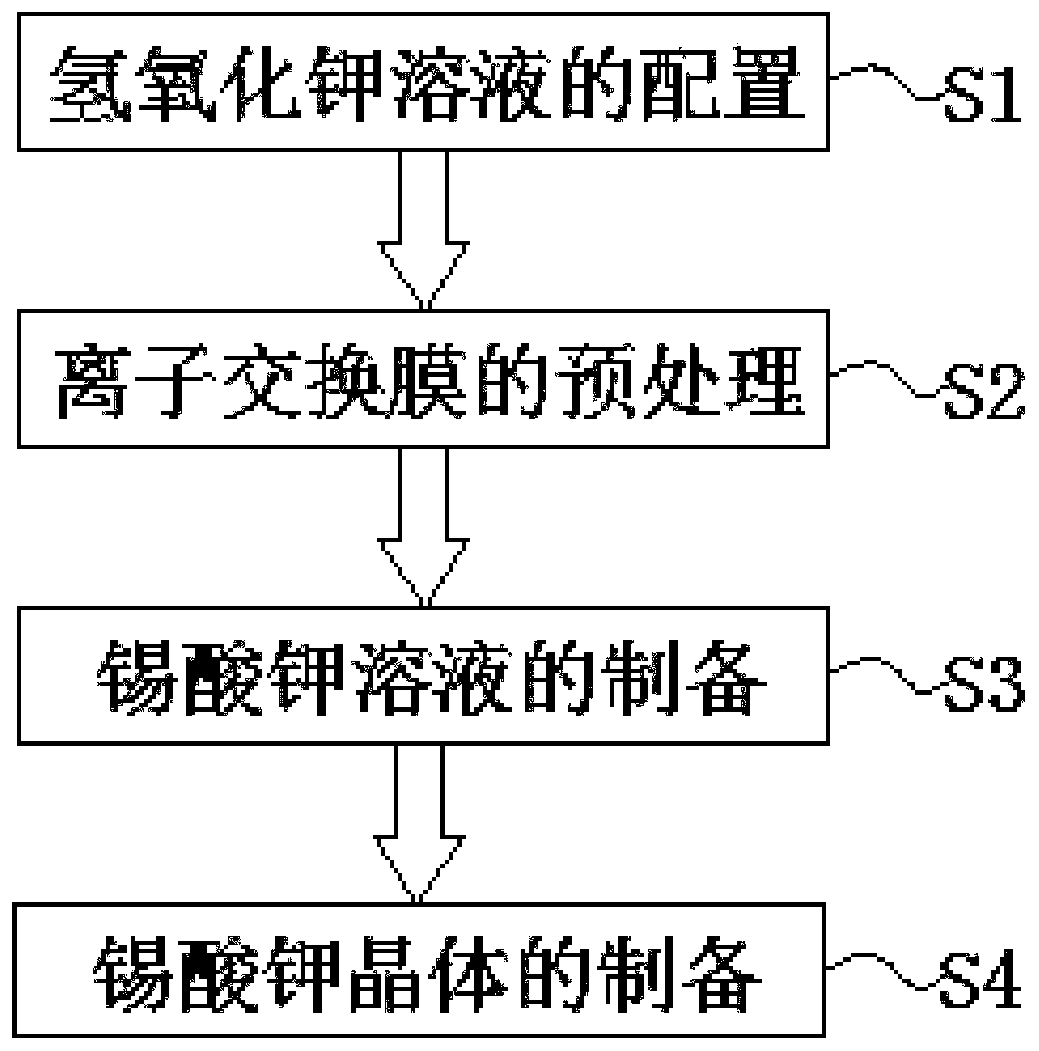

[0019] A kind of preparation method of high-purity potassium stannate proposed by the present embodiment comprises the steps:

[0020] S1, the configuration of potassium hydroxide solution: configure a potassium hydroxide solution with a mass concentration of 10% to 20%, and filter it for later use; it should be noted that the concentration of the potassium hydroxide solution is preferably 12% to ensure subsequent reactions High crystallization rate and strong fluidity.

[0021] S2, pretreatment of ion-exchange membrane: Install the ion-exchange membrane into the isolated electrolytic cell, inject the potassium hydroxide solution configured in S1 into the anode area, inject pure water into the cathode area, and detect the cathode area and the anode area after standing for a period of time The content of chloride and sulfate, make the content of chloride and sulfate less than 10ppm, complete the pretreatment of ion exchange membrane;

[0022] S3, preparation of potassium stann...

Embodiment 1

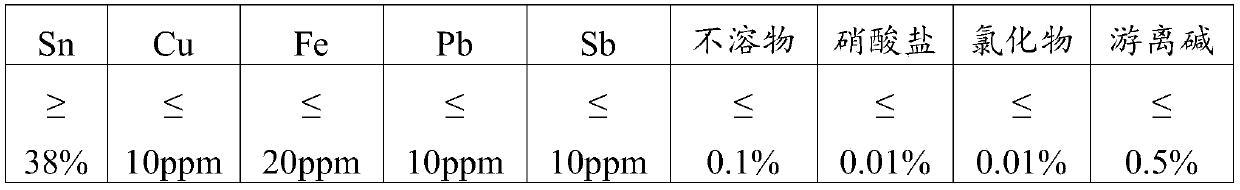

[0030] Add pure water into the dosing tank to start stirring, add a certain amount of potassium hydroxide to make the mass concentration of potassium hydroxide 20%, and then add the potassium hydroxide solution to the 40mm thick tin anode plate and 10mm thick stainless steel Diaphragm electrolyzer of the plate, the cathode and anode areas are separated by anion heterogeneous exchange membrane, and the current density is adjusted to 3.0A / dm 2 , the temperature is 80°C, when the mass concentration of tin ions in the anode area is 10%, take out the electrolyte in the anode area, re-inject 20% potassium hydroxide solution, and continue the electrolysis. After filtering the electrolyte in the anode area, Heating and concentrating under reduced pressure in a vacuum until most of the crystals appear, cooling to room temperature, centrifuging and sieving to obtain high-purity potassium stannate trihydrate crystals.

Embodiment 2

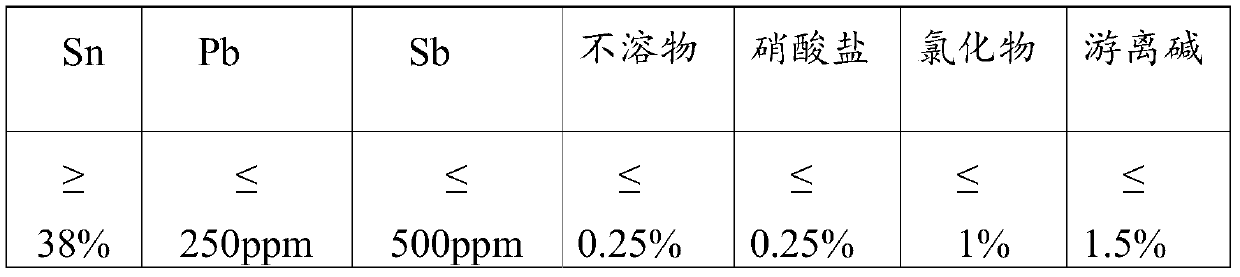

[0032] Add pure water into the dosing tank to start stirring, add a certain amount of potassium hydroxide to make the mass concentration of potassium hydroxide 10%, and then add the potassium hydroxide solution to the 30mm thick tin anode plate and 5mm thick stainless steel Diaphragm electrolyzer of the plate, the cathode and anode areas are separated by anion heterogeneous exchange membrane, and the current density is adjusted to 2.0A / dm 2 , electrolysis at a temperature of 70°C, when the mass concentration of tin ions in the anode area is 5%, take out the electrolyte in the anode area, re-inject 5% potassium hydroxide solution, continue electrolysis, and filter the electrolyte in the anode area Afterwards, high-purity potassium stannate trihydrate was obtained after vacuum concentration, centrifuge separation and vacuum drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com