Dry-mixed plastering mortar and preparation method thereof

A plastering mortar and dry mixing technology, applied in the field of plastering mortar, can solve the problems of surface cracking, peeling off, poor thermal conductivity and bonding strength of mortar, and improve impermeability, prevent cracking and other problems. Falling off, good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-3

[0034] In the preparation example 1-3, graphene is selected from Zhengzhou Yaoshun Chemical Co., Ltd., whose article number is 1005 graphene, and polypropylene fiber is selected from the polypropylene fiber of JBX008 sold by Yibo Chemical Co., Ltd. in Dacheng County, silicon carbide Selected from DFBT-T type silicon carbide micropowder sold by Dengfeng Baotong Refractory Co., Ltd., fatty acid sodium selected from JH type fatty acid sodium sold by Ningbo Jiahe New Material Technology Co., Ltd., styrene and butadiene copolymerized rubber powder selected from Shijiazhuang Xinyuan Cellulose Co., Ltd. sells SBR type redispersible latex powder.

preparation example 1

[0035] Preparation example 1: according to the proportioning in table 1, 5kg graphene and 10kg silicon carbide are stirred 5min under the rotating speed of 500r / min, after adding 30kg mass fraction is the ethanol of 90%, grind 5min, to particle diameter, be 2mm, Then dry at 50°C for 5 minutes, and then mix evenly with 10kg modified starch ether, 5kg polypropylene fiber, 10kg fatty acid salt, 10kg styrene and butadiene copolymerized rubber powder to prepare an admixture, in which modified starch ether It is etherified modified starch S301, the diameter of polypropylene fiber is 10 μm, the length is 2 mm, and the fatty acid salt is sodium fatty acid.

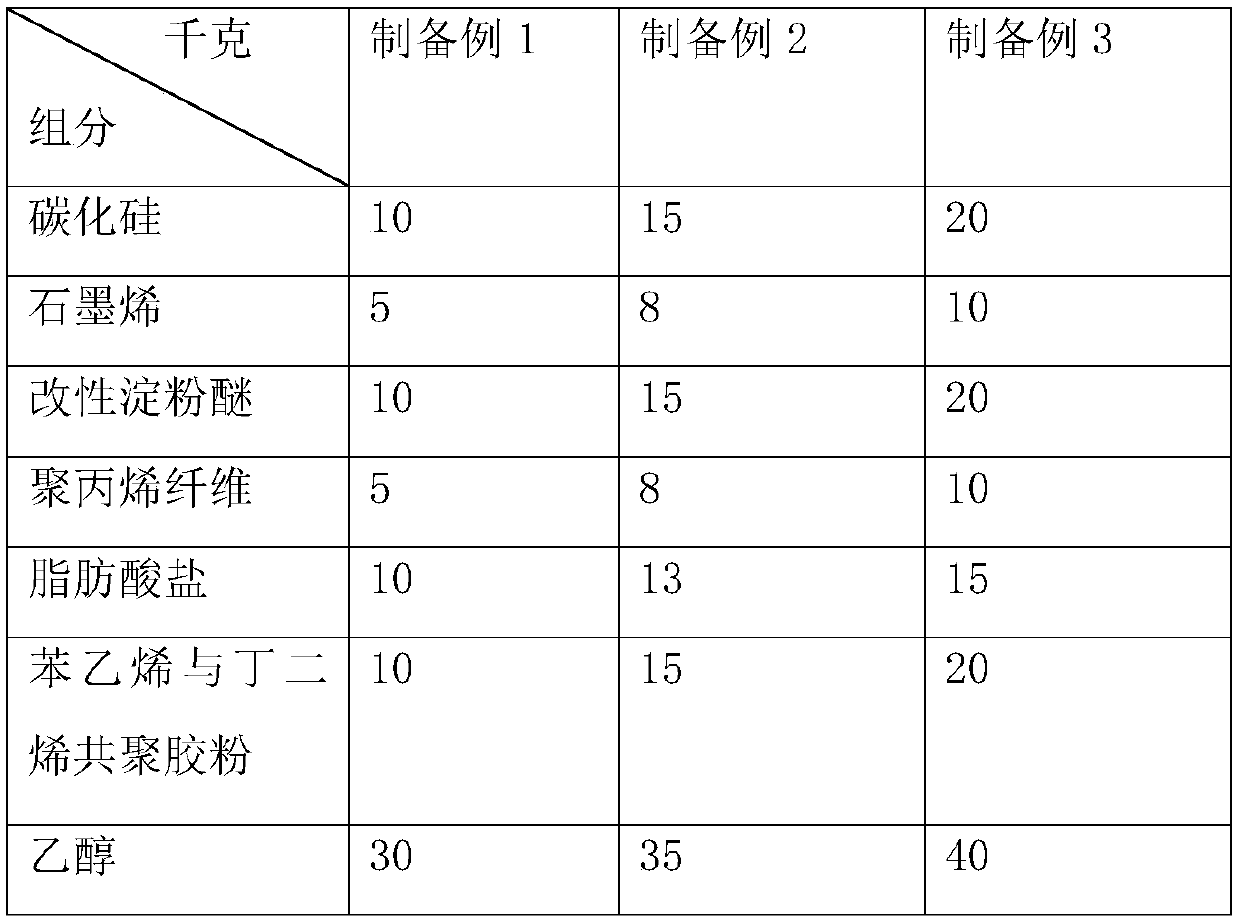

[0036] The raw material ratio of admixture in table 1 preparation example 1-3

[0037]

preparation example 2

[0038] Preparation Example 2: According to the proportioning in Table 1, 8kg of graphene and 15kg of silicon carbide were stirred at a speed of 550r / min for 8min, and after adding 35kg of ethanol with a mass fraction of 93%, they were ground for 8min until the particle size was 2.3mm , and then dried at 55°C for 8 minutes, and then mixed evenly with 15kg modified starch ether, 8kg polypropylene fiber, 13kg fatty acid salt, 15kg styrene and butadiene copolymerized rubber powder to prepare an admixture, in which modified starch The ether is modified starch ether SB250, the diameter of the polypropylene fiber is 20 μm, and the length is 6 mm, and the fatty acid salt is sodium fatty acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com