Method for growing multilayer tungsten diselenide single crystal by molten salt assisted chemical vapor deposition

A technology of chemical vapor deposition and tungsten diselenide, which is applied in the field of two-dimensional materials, can solve the problems of inability to realize double-layer and multi-layer controllable growth, poor performance, small single-layer size, etc., and achieve good dissolution and transportation capacity, The effect of less defect vacancies and enhanced size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

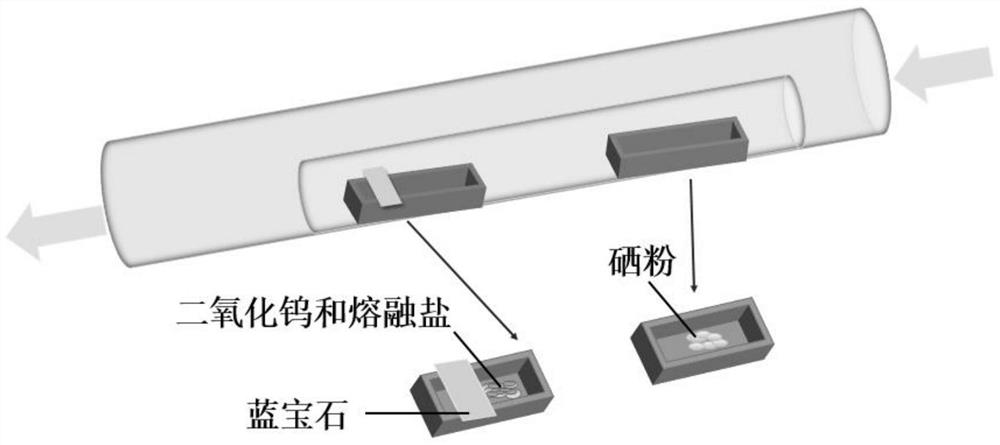

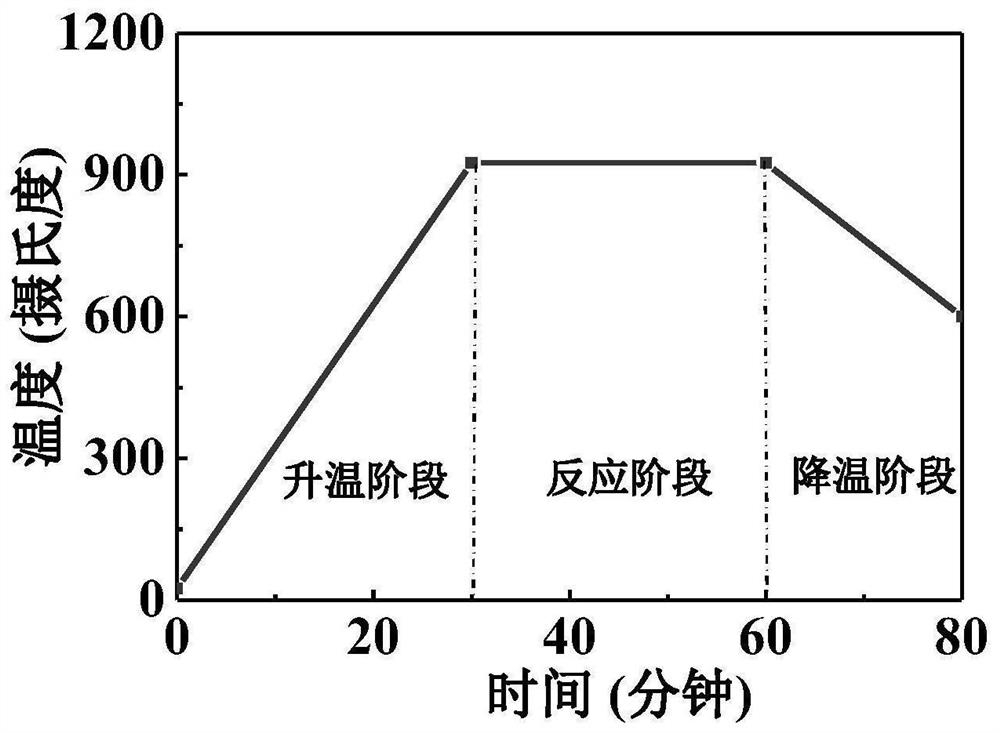

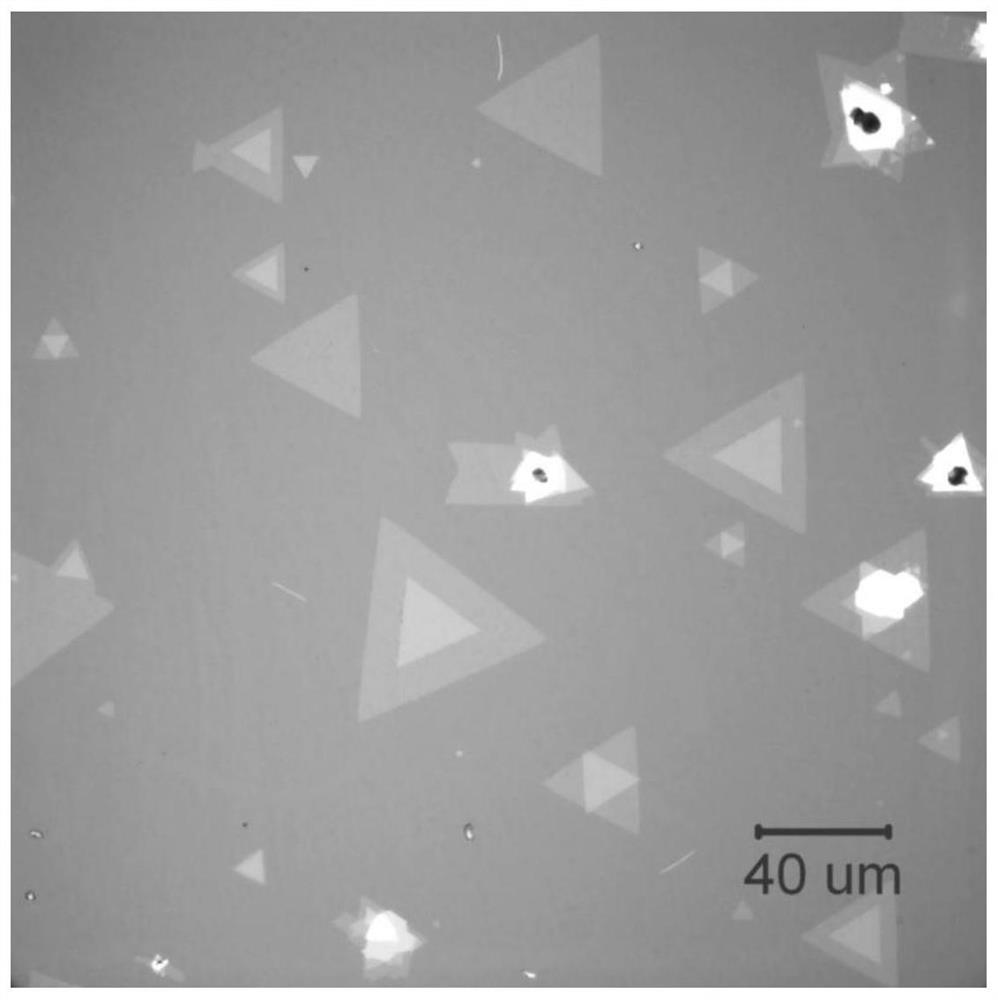

[0051] Taking the growth of double-layer tungsten diselenide as an example, this example provides a method for growing double-layer tungsten diselenide by halide molten salt assisted chemical vapor deposition. The equipment diagram is as follows figure 1 As shown, the specific operation steps are as follows:

[0052] 1. Cleaning the substrate: Clean the pre-prepared sapphire substrate in the order of acetone, isopropanol, and deionized water, each ultrasonic cleaning for 10 minutes, and blow dry with a nitrogen gun after each step. Put it into a plasma cleaning machine for the final cleaning process. The parameter flow rate of argon gas is set to 40 standard milliliters per minute, the oxygen is 10 standard milliliters per minute, the power is a medium power of 10.15 watts, and the processing time is 3 minutes for a long time. After the cleaning process is completed, the entire sapphire substrate is cut into pieces of appropriate size on the processing table to match the corun...

Embodiment 2

[0068] In this embodiment, the mass and distance settings of the source are mainly changed, corundum boats with different boat depths are used, and the halide is selected as sodium chloride. This embodiment specifically includes the following steps:

[0069] 1. Cleaning the substrate: Clean the pre-prepared sapphire substrate in the order of acetone, isopropanol, and deionized water, each ultrasonic cleaning for 10 minutes, and blow dry with a nitrogen gun after each step. Put it into a plasma cleaning machine for the final cleaning process. The parameter flow rate of argon gas is set to 40 standard milliliters per minute, the oxygen is 10 standard milliliters per minute, the power is a medium power of 10.15 watts, and the processing time is 3 minutes for a long time. After the cleaning process is completed, the entire sapphire substrate is cut into pieces of appropriate size on the processing table to match the corundum boat.

[0070] 2. Weigh the sample: Use an electronic s...

Embodiment 3

[0076] In this embodiment, the type of halide is mainly changed, potassium iodide is selected as the halide, corundum boats with different boat depths are used, and the distance setting is changed. This embodiment specifically includes the following steps:

[0077] 1. Cleaning the substrate: Clean the pre-prepared sapphire substrate in the order of acetone, isopropanol, and deionized water, each ultrasonic cleaning for 10 minutes, and blow dry with a nitrogen gun after each step. Put it into a plasma cleaning machine for the final cleaning process. The parameter flow rate of argon gas is set to 40 standard milliliters per minute, the oxygen is 10 standard milliliters per minute, the power is a medium power of 10.15 watts, and the processing time is 3 minutes for a long time. After the cleaning process is completed, the entire sapphire substrate is cut into pieces of appropriate size on the processing table to match the corundum boat.

[0078]2. Weigh the sample: Use an electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com