Nickel phosphate/nickel oxide composite material as well as preparation method and application thereof

A composite material and nickel oxide technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problem of reducing the contact area between catalyst and solution, failing to make full use of active substances, and oxygen evolution catalytic performance No outstanding problems, to achieve excellent oxygen evolution catalytic performance, to avoid the decline of catalytic activity, and to achieve the effect of excellent oxygen evolution catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

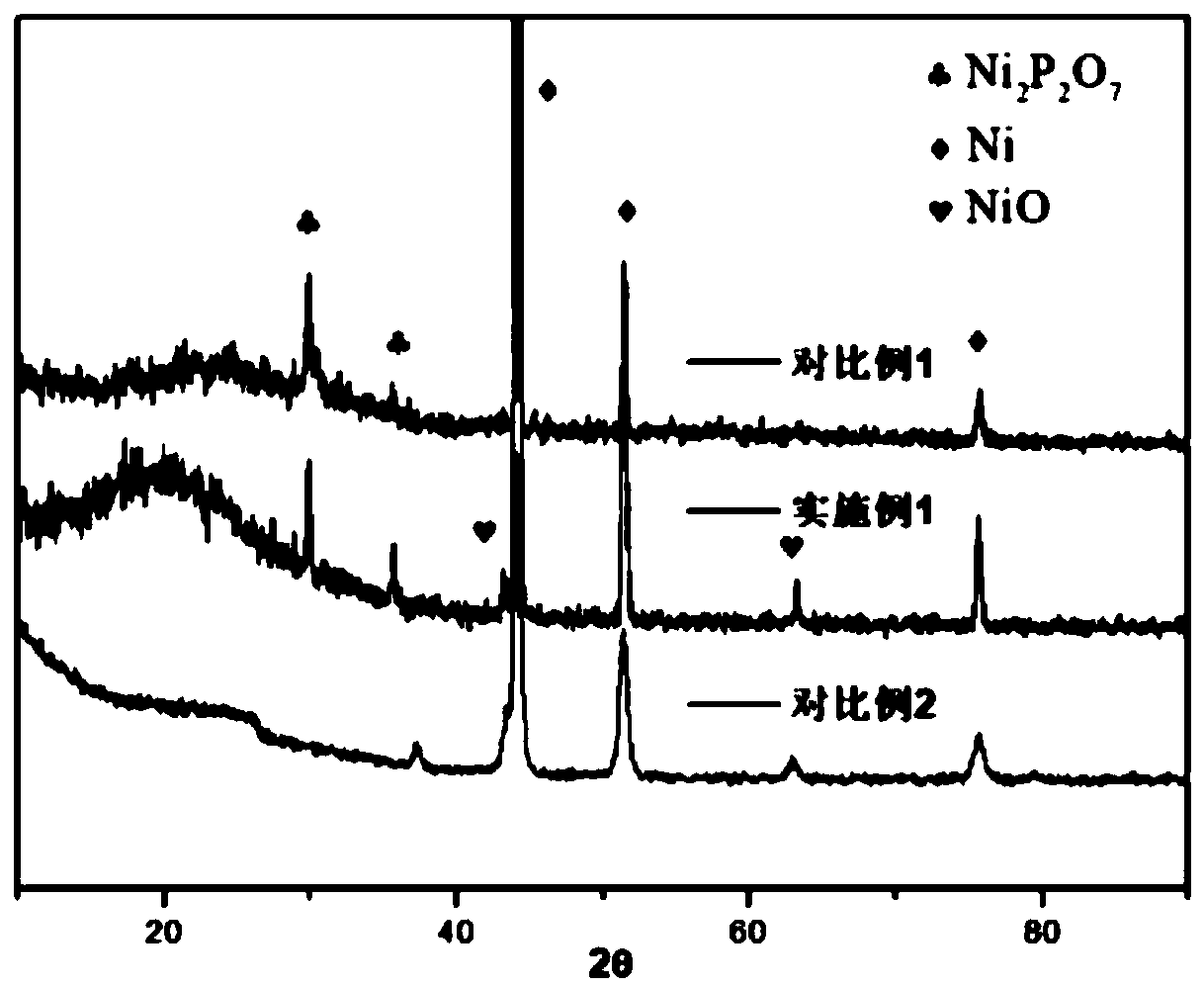

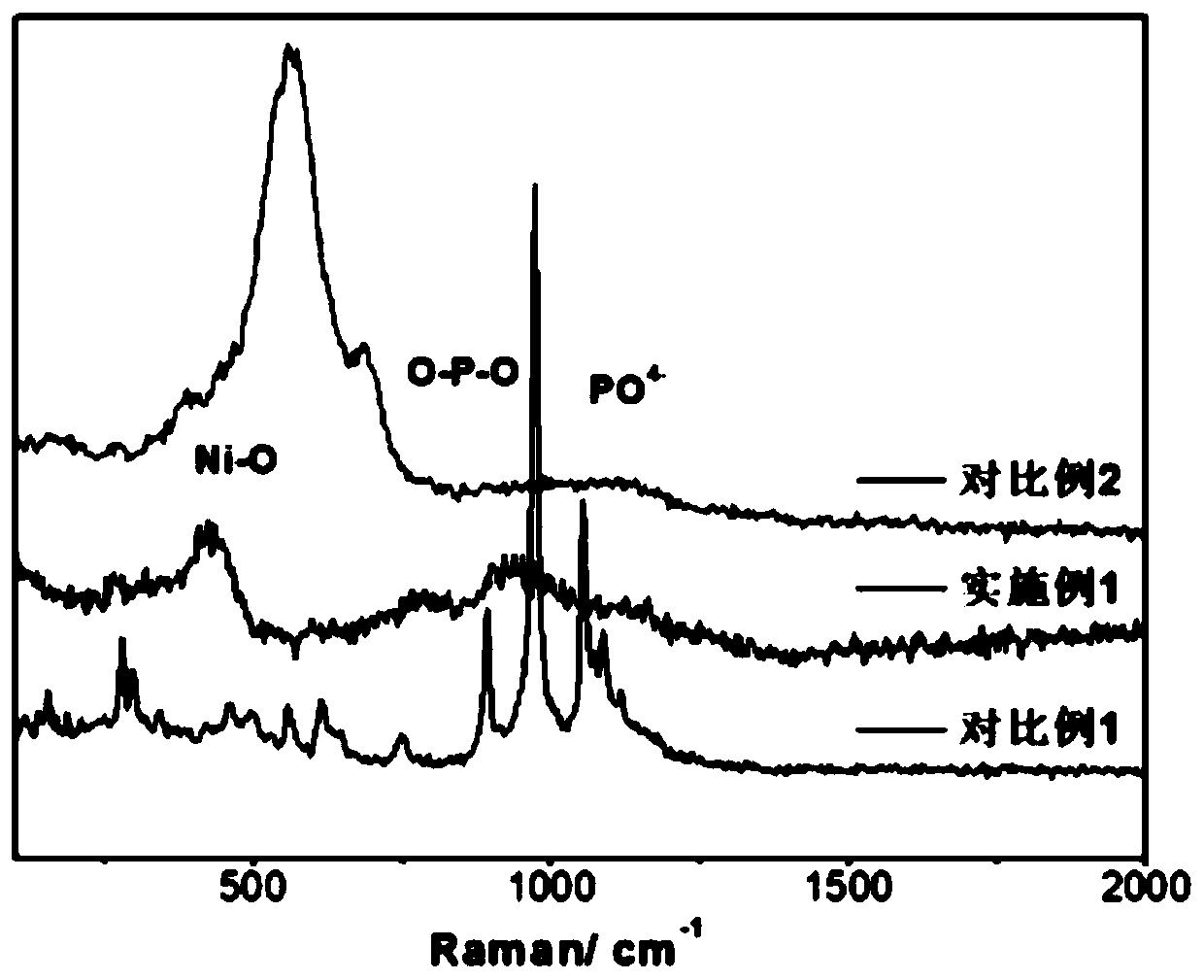

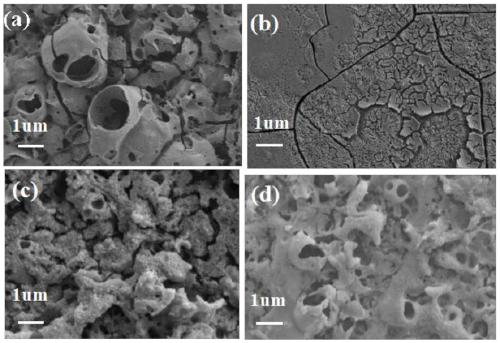

[0033] A kind of preparation method of nickel phosphate / nickel oxide composite catalyst of the present embodiment, comprises the following steps:

[0034] (1) Sample preparation: the selected Ni-Fe alloy (composition of 79wt.% Ni, 18wt.% Fe, 3wt.% impurity) with a thickness of 0.2mm was cut into a rectangle of 3.5cm×0.5cm, where the length The upper half of 1.5cm is the clamping part, which is used to connect with the fixture, and the lower half of the substrate is inserted into the electrolyte for micro-arc oxidation.

[0035] (2) Sample cleaning: put the cut alloy in acetone and ultrasonically clean it for 15 minutes, take out the sample, and then put it in absolute ethanol for 10 minutes. Then rinse the sample with a large amount of deionized water, put it in a drying oven and dry it for later use.

[0036] (3) Micro-arc oxidation: Dissolve sodium phosphate, sodium citrate, and EDTA-2Na in deionized water, wherein the concentration of sodium phosphate is 0.2mol / L, the conc...

Embodiment 2

[0050] (1) Sample preparation: same as step (1) in Example 1.

[0051] (2) Sample cleaning: same as step (2) in Example 1.

[0052] (3) Micro-arc oxidation: Dissolve sodium phosphate, sodium citrate, and EDTA-2Na in deionized water, wherein the concentration of sodium phosphate is 0.2mol / L, the concentration of sodium citrate is 0.02mol / L, and the concentration of EDTA-2Na The concentration is 0.02mol / L. Use H 2 SO 4 The pH of the solution is adjusted so that the pH of the final solution is 7. The Ni-Fe alloy pretreated in steps (1) and (2) is used as the anode, and the graphite is used as the cathode, and then micro-arc oxidation is performed. The micro-arc oxidation voltage is 120V, the micro-arc oxidation time is 0.5min, and a layer of nickel phosphate / nickel oxide composite film is formed in situ on the surface of the anode substrate. After completion, take out the sample, and rinse off the residual solution on the surface of the sample with a large amount of deionized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com