Regulator for emulsion polymerization and preparation method thereof

A technology of emulsion polymerization and regulator, which is applied in the field of emulsion polymerization, can solve problems affecting polymerization efficiency and product quality, increase system viscosity, hinder polymerization reaction, etc., and achieve the effect of improving polymerization efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention provides a kind of preparation method of regulator for emulsion polymerization, comprising the following steps:

[0039] a) mixing hydrogen peroxide, electrolyte, co-stabilizer and modifier to obtain a hydrogen peroxide-based modification solution;

[0040] b) After mixing and reacting the hydrogen peroxide-based modification solution with a soluble sodium salt solution, drying to obtain a regulator powder;

[0041] c) Melting the straight-chain saturated fatty acid and mixing it with the conditioner powder, and spray drying to obtain microcapsule conditioner particles.

[0042] The present invention mixes hydrogen peroxide, electrolyte, co-stabilizer and modifier to form a hydrogen peroxide-based modified liquid; then mixes it with a soluble sodium salt solution and dries it to obtain regulator powder; The fatty acid is mixed with the conditioner powder, and the conditioner powder is coated to obtain microcapsule-type conditioner particles with a core-sh...

Embodiment 1

[0078] S1. Take 650g of sodium carbonate, add deionized water, stir and dissolve at 35°C, and obtain a saturated solution of sodium carbonate with a concentration of 45% by hot suction filtration.

[0079] S2. Take 1167g hydrogen peroxide solution (30% concentration), add 150g potassium chloride, 100g sodium phosphate, 1.5g sodium methylene dinaphthalenesulfonate, 0.5g sodium methylnaphthalenesulfonate, 0.5g EDTA-2Na, stir well , to obtain hydrogen peroxide-based modified liquid.

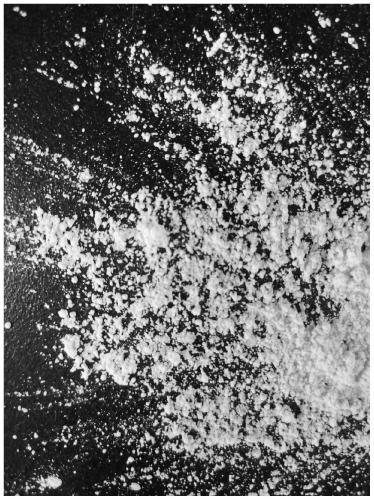

[0080] S3, control the feed rate of the metering pump, the feed rate of saturated sodium carbonate solution is 50mL / min, the feed rate of hydrogen peroxide-based modified liquid is 42mL / min, and enter the three-stage static mixer (single section length 2m, pipeline diameter 1.2 cm), the first stage is 35°C and stays for 3 minutes, the second stage is 25°C and stays for 3 minutes, the third stage is 15°C and stays for 3 minutes. Drying, after being ground by a grinder, passing through a 100-mesh sie...

Embodiment 2

[0086] S1. Take 750 g of sodium carbonate, add deionized water, stir and dissolve at 35° C., and obtain a saturated solution of sodium carbonate with a concentration of 45% through hot suction filtration.

[0087] S2. Take 834g hydrogen peroxide solution (concentration 30%), add potassium chloride 100g, sodium metaphosphate 100g, sodium methylene dinaphthalenesulfonate 0.5g, sodium naphthalenesulfonate 1g, EDTA-2Na 0.5g, EDTA-4Na 0.3 g, stir evenly to obtain a hydrogen peroxide-based modified liquid.

[0088] S3, control the feed rate of the metering pump, the feed rate of saturated sodium carbonate solution is 60mL / min, the feed rate of hydrogen peroxide-based modified liquid is 30mL / min, and enter the three-stage static mixer (single section length 2m, pipeline diameter 1.2 cm), the first stage is 35°C, stay for about 3min, the second stage is 25°C, stay for about 3min, the third stage is 15°C, stay for about 3min, after fully reacting, enter the 12°C low-temperature tank, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| mechanical stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com