Preparation method of fusiform platinum nanoparticles

A platinum nanoparticle, shuttle-shaped technology, applied in the field of preparation of shuttle-shaped platinum nanoparticles, can solve the problems of expressing catalytic performance, not easy to remove, limiting the exposure of platinum group metal nanoparticles surface active sites, etc., which affect the catalytic activity, and achieve Improve the electrochemical active area, avoid adsorption, and improve the effect of electrocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

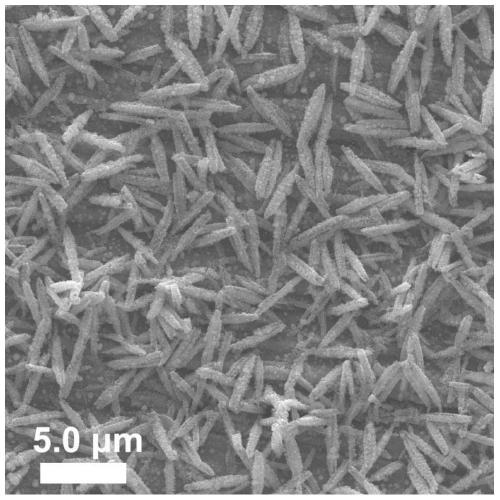

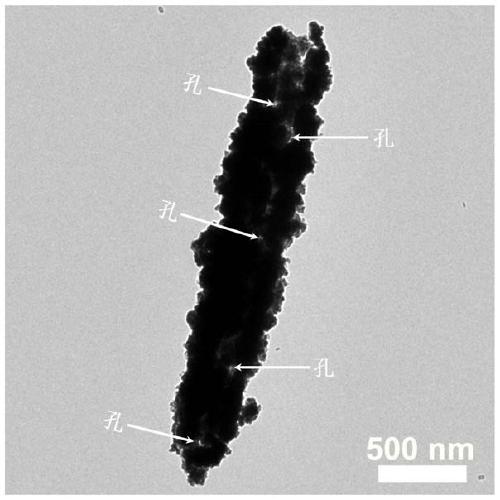

[0032] A preparation method for spindle-shaped platinum nanoparticles, comprising the following steps:

[0033] (1) Polish the titanium sheet with a purity of 99.99% and a length and width of 10×10 cm with TiC sandpaper of 300 mesh and 800 mesh for 1 hour respectively until the surface of the titanium sheet is bright, and then cut the polished titanium sheet to a length and width of 2.5×1.0 cm, and then ultrasonically clean the cut titanium sheet with 5vt% hydrochloric acid, absolute ethanol, and deionized water for 5 minutes, and finally dry it for later use.

[0034] (2) The titanium sheet prepared in step (1) was used as the working electrode, and a spectroscopically pure graphite rod with a diameter of 0.6 cm and a length of 10 cm was used as an auxiliary electrode. It was deposited in an electrolyte solution with a volume of 10 mL at 25 ° C for 90 min, wherein the The concentration of chloroplatinic acid in the electrolyte is 0.5mmol / L, the concentration of zinc nitrate i...

Embodiment 2

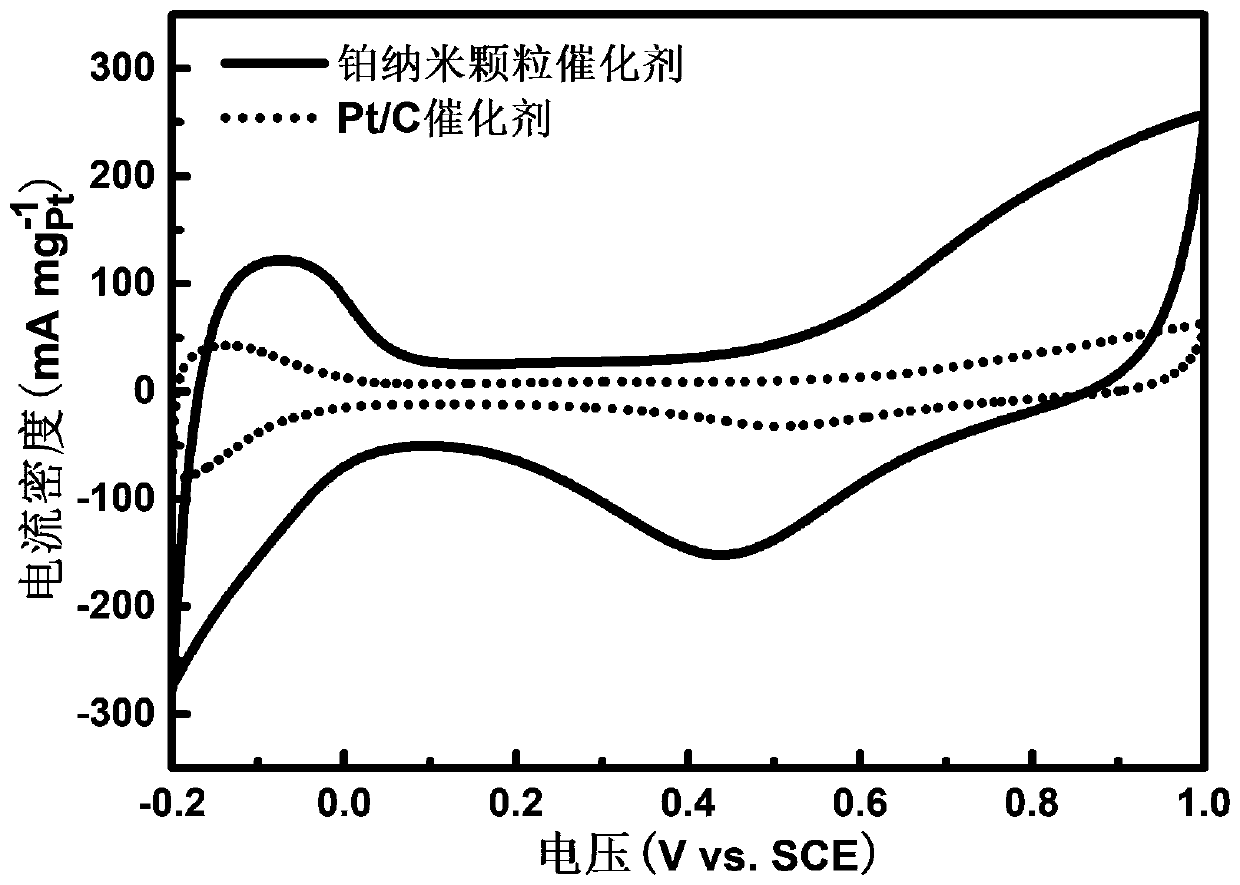

[0040] A preparation method of shuttle-shaped platinum nanoparticles is basically the same as the preparation method of Example 1, except that in the electrolyte, the concentration of chloroplatinic acid is 1.0mmol / L, the concentration of zinc nitrate is 10mmol / L, ammonium acetate The concentration is 10mmol / L. The morphology of the shuttle-shaped platinum nanoparticles prepared in this example is relatively regular, and the loading capacity of Pt is about 74.2 μg / cm 2 , the current density of its catalytic methanol oxidation can reach 680mA / mg Pt .

Embodiment 3

[0042] A preparation method of spindle-shaped platinum nanoparticles is basically the same as the preparation method in Example 1, except that the electrodeposition time is changed to 120 minutes. The morphology of the shuttle-shaped platinum nanoparticles prepared in this example is relatively regular, and the loading capacity of Pt is about 94.3 μg / cm 2 , the current density of its catalytic methanol oxidation can reach 580mA / mg Pt .

[0043] In summary, the porous shuttle-shaped platinum nanoparticles synthesized by the preparation method of the present invention have the advantages of regular shape, uniform size, large specific surface area, excellent electrocatalytic performance, etc., and have high use value and good application prospects; at the same time, The preparation method of the present invention is a simple and easy constant current electrodeposition synthesis method, which has the advantages of low energy consumption, simple and easy access to raw materials, g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com