Preparation method and application of DN hydrogel (double network hydrogel) containing squid II gelatin

A hydrogel and double-network technology, applied in prostheses, tissue regeneration, medical science, etc., can solve problems such as the compression strength not meeting the requirements for costal cartilage repair, poor mechanical properties of hydrogel, discomfort for costal cartilage defects, etc. Achieve the effects of preventing collapse, good biocompatibility, and repairing costal cartilage defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1. Preparation of squid type II gelatin-[4-Arm PEG-SS]-HAMA double network hydrogel.

[0040] After removing the attached muscles of squid cartilage, it is vacuum freeze-dried and crushed into cartilage powder. Add EDTA solution at room temperature, stir slowly for 24 hours, centrifuge and wash the precipitate with deionized water, then add NaOH solution and stir slowly for 24 hours. Centrifuge and completely wash the precipitate with deionized water, add 0.5M acetic acid solution and pepsin, slowly stir and hydrolyze at 37°C, then heat to 50°C for about half an hour, then filter, and put it into a dialysis bag with a molecular weight cutoff of 10kDa to pure Water was used as the external fluid for dialysis and dialyzed for 3 days at room temperature. The dialyzed glue was vacuum freeze-dried to obtain squid type II gelatin.

[0041] Dissolve 1g hyaluronic acid (48kDa) in 100mL deionized water, cool to 0~4℃, add 4mL methacrylic anhydride, and then slowly add 2mL 5M N...

Embodiment 2

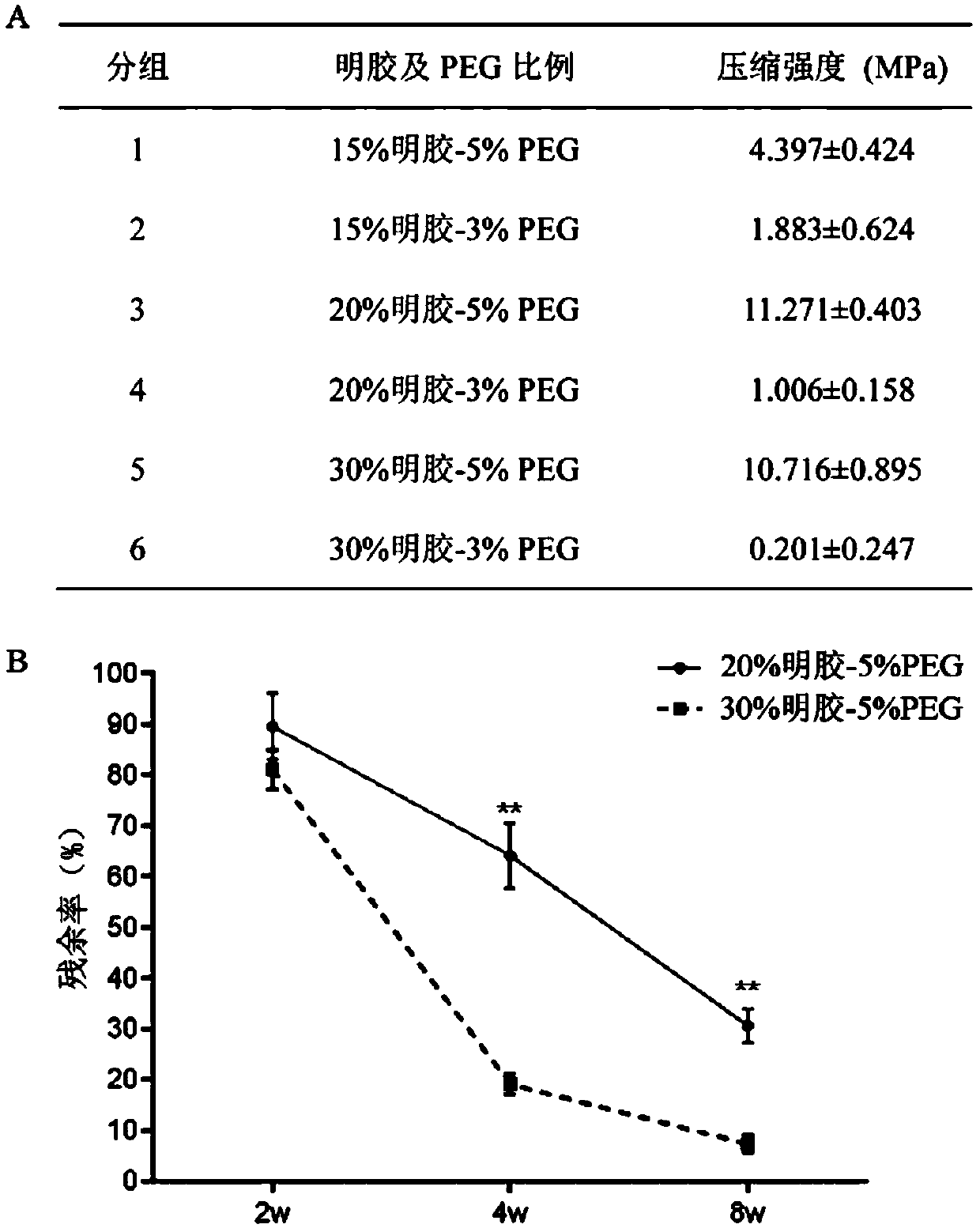

[0048] Example 2. Test of mechanical strength of squid type II gelatin-[4-Arm PEG-SS]-HAMA double network hydrogel

[0049] The mechanical performance analysis adopts GT-TCS-2000 polymer tensile machine, and the prepared hydrogel sample is placed on the test platform for testing. This example studied the influence of the concentration of squid type II gelatin and PEG on the mechanical strength of the hydrogel. figure 2 A is the compressive strength of the hydrogel prepared in each ratio in Table 1. It can be seen that when the final concentration of gelatin is 20% or 30%, and the final concentration of PEG is 5%, the prepared squid type II gelatin-[4-Arm PEG-SS]-HAMA double network hydrogel The strength is the best, and when the final concentration of gelatin is 15%, even if the final concentration of PEG reaches 5%, the mechanical strength of the resulting hydrogel is still poor.

Embodiment 3

[0050] Example 3. Degradability detection of squid type II gelatin-[4-Arm PEG-SS]-HAMA double network hydrogel

[0051] Prepare 20% gelatin-5% PEG hydrogel and 30% gelatin-5% PEG hydrogel as described in Example 1. Before preparing the hydrogel, use irradiation to sterilize squid type II gelatin. Aseptic operation was maintained during the hydrogel process, and the HAMA / 12959 mixture and PEG solution were subjected to suction filtration and sterilization with a 0.22 μm filter, and finally a sterile hydrogel was obtained. The hydrogel sample was weighed and immersed in sterile PBS, sealed and placed in a 37°C environment, and the residual rate of the hydrogel was tested after 2, 4, and 8 weeks. From figure 2 It can be seen from B that the degradation rate of hydrogels containing 30% gelatin is higher than that of hydrogels containing 20% gelatin (** means p<0.01), which may be because 20% gelatin-5%PEG-1%HAMA- The ratio of amino and carboxyl groups in the 0.1% I2959 hydrogel m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com