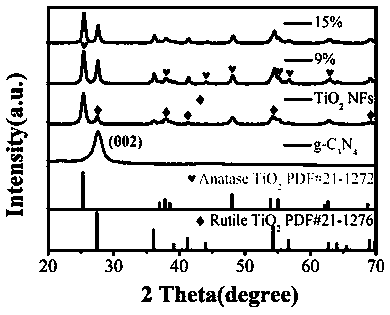

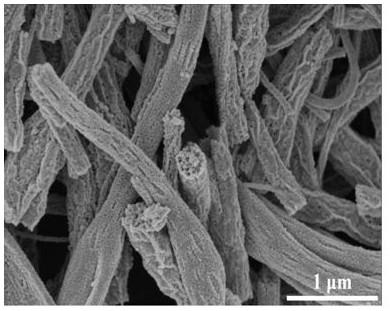

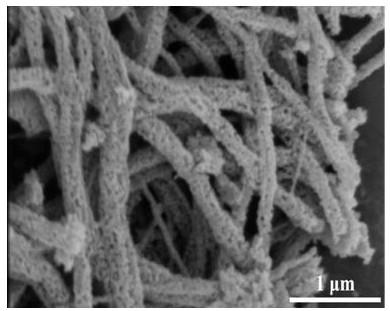

One-step method for preparing hierarchical mesoporous-porous TiO2/g-C3N4 nanofiber photocatalytic material

A technology of photocatalytic materials and nanofibers, applied in the field of photocatalytic materials, to achieve the effects of large specific surface area, small diameter of product fibers, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Add N,N-dimethylformamide and glacial acetic acid in sequence to absolute ethanol at a volume ratio of 4:3:1, and mix well to obtain solution A;

[0032] 2) Add urea with a mass ratio of 2.5% to solution A to obtain solution B after complete dissolution;

[0033] 3) Add polyvinylpyrrolidone with a mass ratio of 5% to solution B, and stir to obtain solution C;

[0034] 4) Add tetrabutyl titanate solution with a volume ratio of 6.25% to solution C, and stir to obtain mixed solution D;

[0035] 5) Add liquid paraffin with a volume ratio of 9% to solution D, and stir for more than 24 hours to obtain solution E;

[0036] 6) Put solution D into a 5mL syringe, install the syringe on the electrospinning device, conduct electrospinning at a voltage of 18KV, a solution supply rate of 1mL / h, and a receiving distance of 20cm, and collect the product with a stainless steel plate;

[0037] 7) After the product is dried, place it in a crucible with a lid and bake it at 550°C for ...

Embodiment 2

[0039] 1) Add N,N-dimethylformamide and glacial acetic acid in sequence to absolute ethanol at a volume ratio of 8:7:1, and mix well to obtain solution A;

[0040] 2) Add urea with a mass ratio of 3.75% to solution A to obtain solution B after complete dissolution;

[0041] 3) Add polyvinylpyrrolidone with a mass ratio of 7.5% to solution B, and stir to obtain solution C;

[0042] 4) Add tetrabutyl titanate solution with a volume ratio of 18.75% to solution C, and stir to obtain mixed solution D;

[0043] 5) Add liquid paraffin with a volume ratio of 15% to solution D, and stir for more than 24 hours to obtain solution E;

[0044] 6) Put solution D into a 5mL syringe, install the syringe on the electrospinning device, conduct electrospinning at a voltage of 18KV, a solution supply rate of 1mL / h, and a receiving distance of 20cm, and collect the product with a stainless steel plate;

[0045] 7) After the product is dried, place it in a crucible with a lid and bake it at 550°C f...

Embodiment 3

[0047] 1) Add N,N-dimethylformamide and glacial acetic acid in sequence to absolute ethanol at a volume ratio of 7:7:2, and mix well to obtain solution A;

[0048] 2) Add urea with a mass ratio of 5% to solution A to obtain solution B after complete dissolution;

[0049] 3) Add polyvinylpyrrolidone with a mass ratio of 8.75% to solution B, and stir to obtain solution C;

[0050] 4) Add tetrabutyl titanate solution with a volume ratio of 31.25% to solution C, and mix well to obtain mixed solution D;

[0051] 5) Add liquid paraffin with a volume ratio of 20% to solution D, and stir for more than 24 hours to obtain solution E;

[0052] 6) Put solution D into a 5mL syringe, install the syringe on the electrospinning device, conduct electrospinning at a voltage of 18KV, a solution supply rate of 1mL / h, and a receiving distance of 20cm, and collect the product with a stainless steel plate;

[0053] 7) After the product is dried, place it in a crucible with a lid and bake it at 550...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com