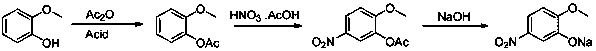

Method for producing 5-nitroguaiacol sodium salt by using micro-channel reaction device

A technology of microchannel reaction and sodium guaiacol, applied in chemical instruments and methods, preparation of nitro compounds, chemical/physical/physical-chemical reactors, etc., can solve the problems of harsh reaction conditions and low product yield, etc. To achieve the effect of short reaction time, improved reaction conversion rate, and controllable reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

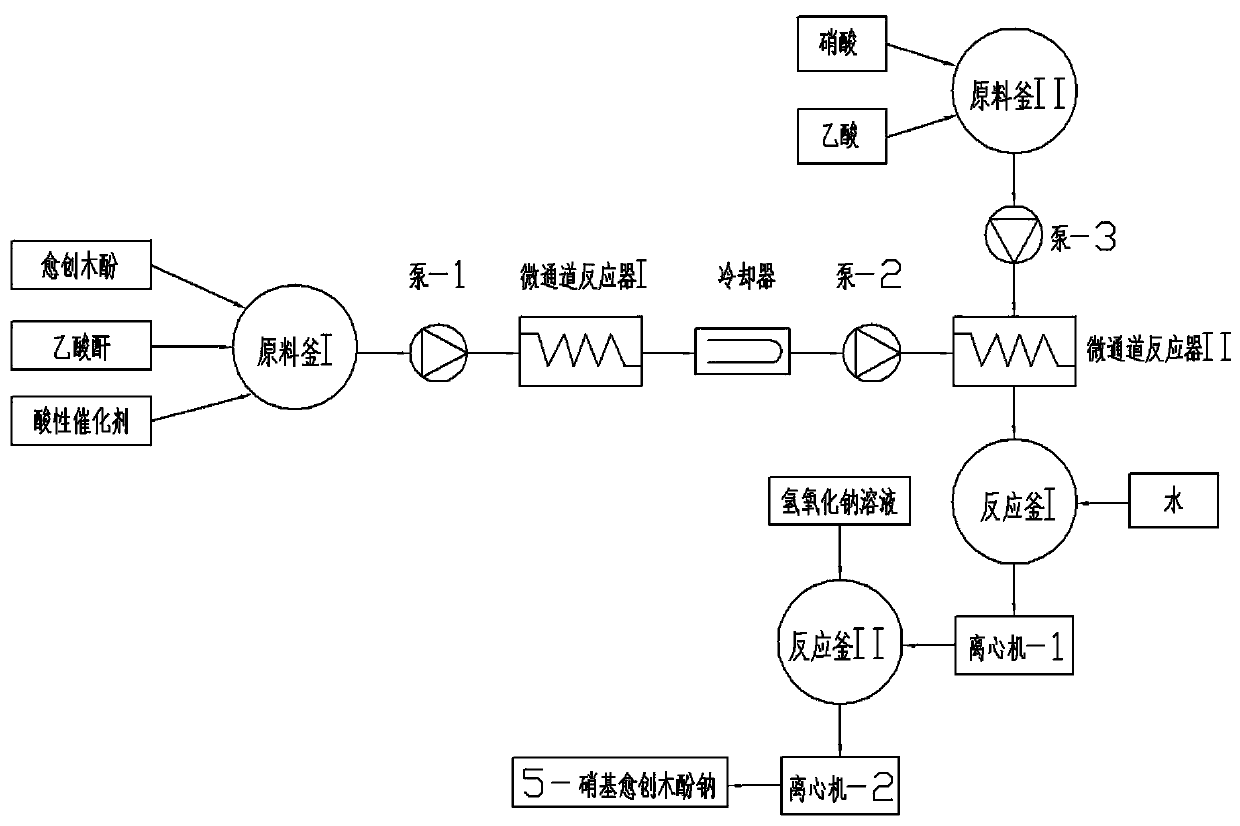

Method used

Image

Examples

Embodiment 1

[0044] Pump the guaiacol-acetic anhydride solution containing the acidic catalyst in the raw material kettle I into the microchannel reactor I for reaction, the mass ratio of guaiacol, acetic anhydride and phosphoric acid is 1:0.86:0.005, and the reaction condition is 120°C Keep at low temperature for 10 minutes to obtain acetylguaiacol solution. The acetylguaiacol solution was cooled to 48° C. for later use. The purity of acetylguaiacol was 99.7% as detected by liquid phase.

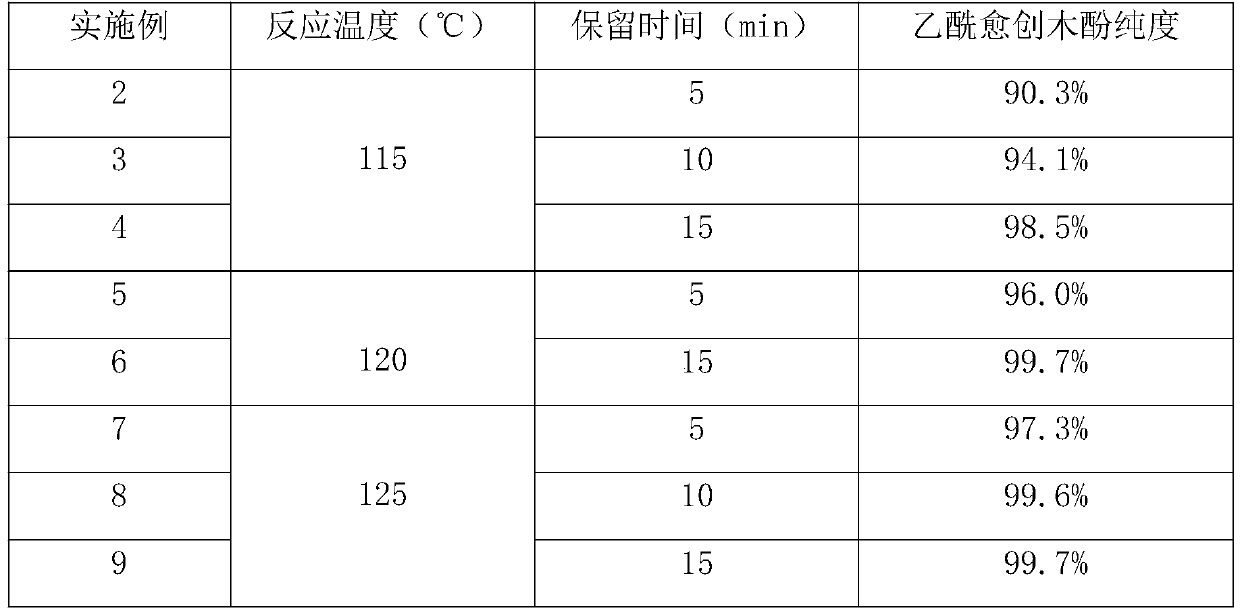

Embodiment 2-9

[0046] Adopt the raw material proportioning identical with embodiment 1, under certain temperature, keep for a period of time, get the acetylguaiacol solution that microchannel reactor 1 comes out and detect.

[0047] The reaction product purity of table 1 embodiment 2-9

[0048]

Embodiment 10-11

[0050] Using the same mass ratio of guaiacol, acetic anhydride and acidic catalyst as in Example 1, the same reaction temperature of 120°C and the same retention time of 10min, the difference is that in Example 10, phosphoric acid is changed to sulfuric acid. 11 Change phosphoric acid to trifluoroacetic acid.

[0051] The reaction product purity of table 2 embodiment 10-11

[0052] Example acid catalyst Acetylguaiacol Purity 10 sulfuric acid 98.5% 11 Trifluoroacetate 99.5%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com