Organic solid-state laser and preparation method based on gold-silver core-shell nanorod-metal thin film

A gold-silver core-shell and metal thin-film technology, applied in the field of lasers, can solve problems such as the quenching of dye molecules, reduce the laser threshold, improve the excitation rate and quantum efficiency, and enhance the effect of random lasers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

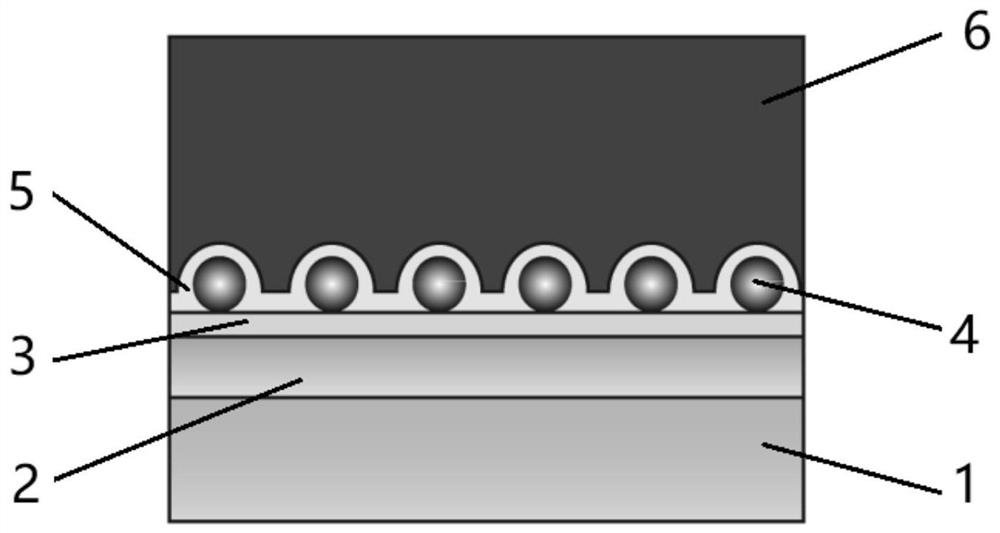

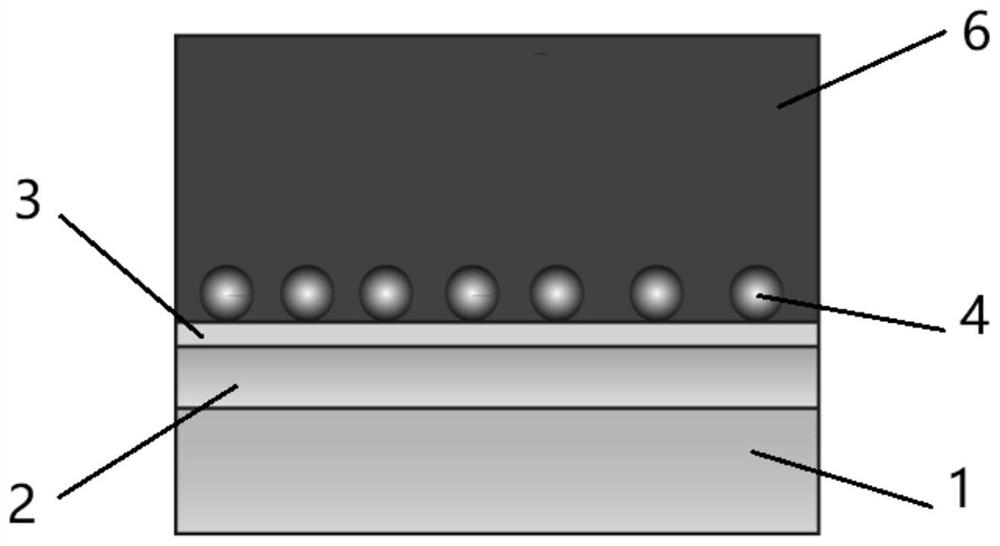

[0032] In this embodiment, an organic solid-state laser based on a gold-silver core-shell nanorod-metal film, specifically as figure 1 As shown, it includes a substrate 1, a metal thin film layer 2, a first isolation medium layer 3, a gold-silver core-shell nanorod structure layer 4, a second isolation medium layer 5, and a gain medium layer 6 that are stacked in sequence; the metal thin film layer 2 It is a silver thin film layer capable of producing non-localized surface plasmon effect SPP, with a thickness of 50nm; the material of the first isolation dielectric layer 3 is SiO 2 , with a thickness of 10nm; the shell material in the gold-silver core-shell nanorod structure layer 4 is Ag, and the thicknesses wrapped around the side and end faces of the gold nanorods are 8nm and 4nm respectively, the central core material is 50nm in length, and the aspect ratio 3 Au nanorods; the material of the second isolation medium layer 5 is LiF, with a thickness of 10nm; the material of t...

Embodiment 2

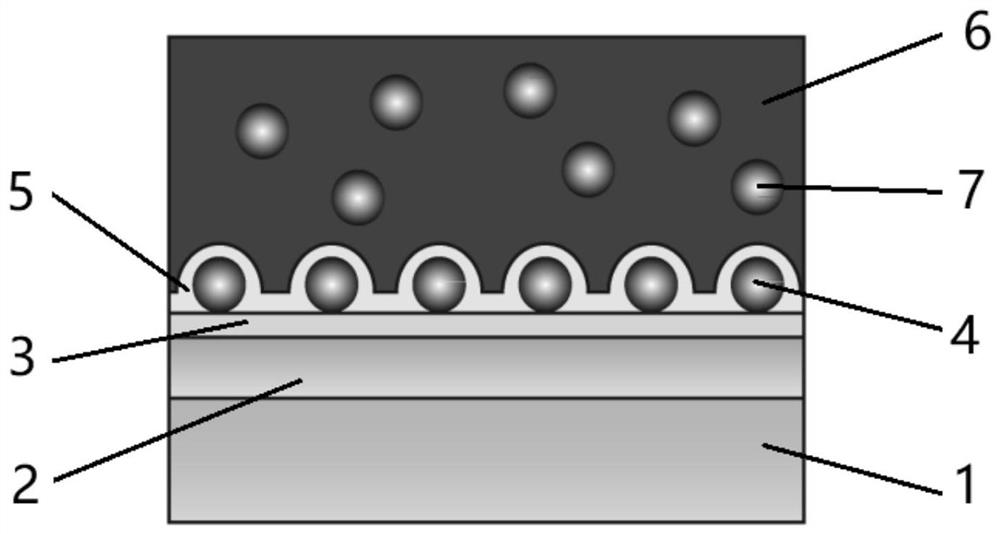

[0041] In this embodiment, an organic solid-state laser based on a gold-silver core-shell nanorod-metal film, specifically as figure 2 As shown, the specific structure of the device is the same as in Embodiment 1, the only difference is that the material of the gain medium layer 6 is made of polystyrene PS, Alq 3 Composed of DCJTB with a mass ratio of 200:100:3.5, and second metal nanoparticles 7 are randomly distributed in the gain medium layer 6, and these second metal nanoparticles 7 are silver that can realize the localized surface plasmon effect LSPR nanospheres, the silver nanospheres have a diameter of 50 nm, and the doping concentration of the second metal nanoparticles 7 in the gain medium layer 6 is 4.55×10 -4 g / cm 3 , the thickness of the gain medium layer 6 is 300 nm.

[0042] The specific device structure is expressed as follows: glass / Ag film (50nm) / SiO 2 (10nm) / Au@Ag NRs / LiF(10nm) / PS:Alq 3 : DCJTB mingled with Ag nanospheres (300nm).

[0043] The method fo...

Embodiment 3

[0047] This embodiment is an organic solid-state laser based on a gold-silver core-shell nanorod-metal thin film. The specific structure of the device is the same as that of Embodiment 2, the only difference being that the silver thin film layer with a thickness of 50 nm is replaced by a gold layer with a thickness of 50 nm. film layer.

[0048] The specific device structure is expressed as follows: glass / Au film(50nm) / SiO 2 (10nm) / Au@Ag NRs / LiF(10nm) / PS:Alq 3 : DCJTB mingled with Ag nanospheres (300nm).

[0049] The above-mentioned organic solid-state laser based on gold-silver core-shell nanorods-metal film is the same as the method provided in Example 2, the only difference is that the gold film needs to be deposited on the substrate by magnetron sputtering, which is not described here. Give specific descriptions one by one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com