Preparation method and application of nitrogen-doped carbon nanotube loaded phosphorus-doped cobaltosic oxide composite material

A technology of cobalt tetroxide and nitrogen-doped carbon, which is applied to carbon nanotubes, carbon compounds, chemical instruments and methods, etc., can solve the problems of low specific capacity and performance to be improved, achieve good electrochemical performance, and promote redox process. , strong adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

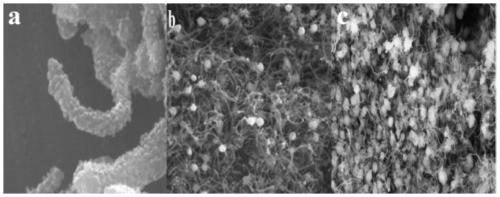

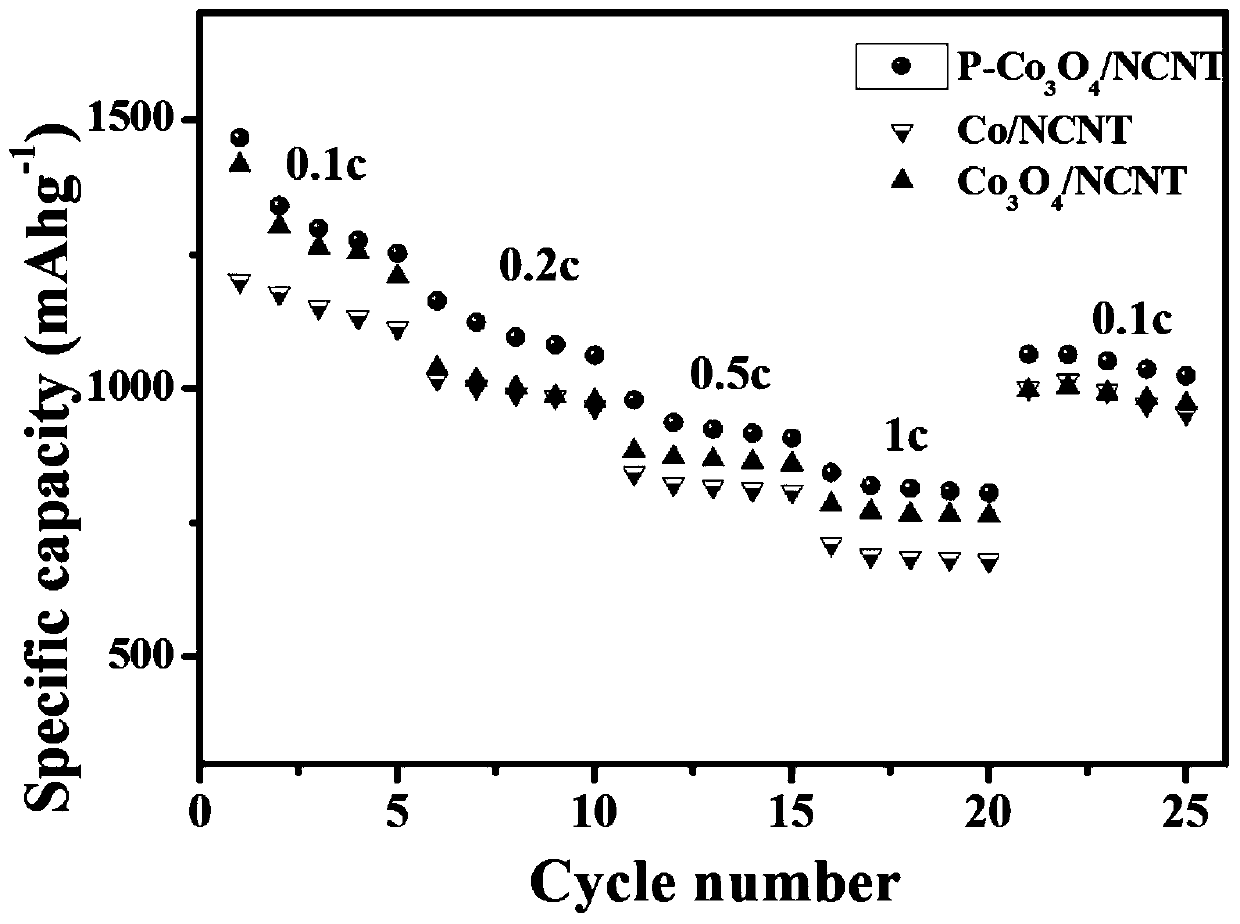

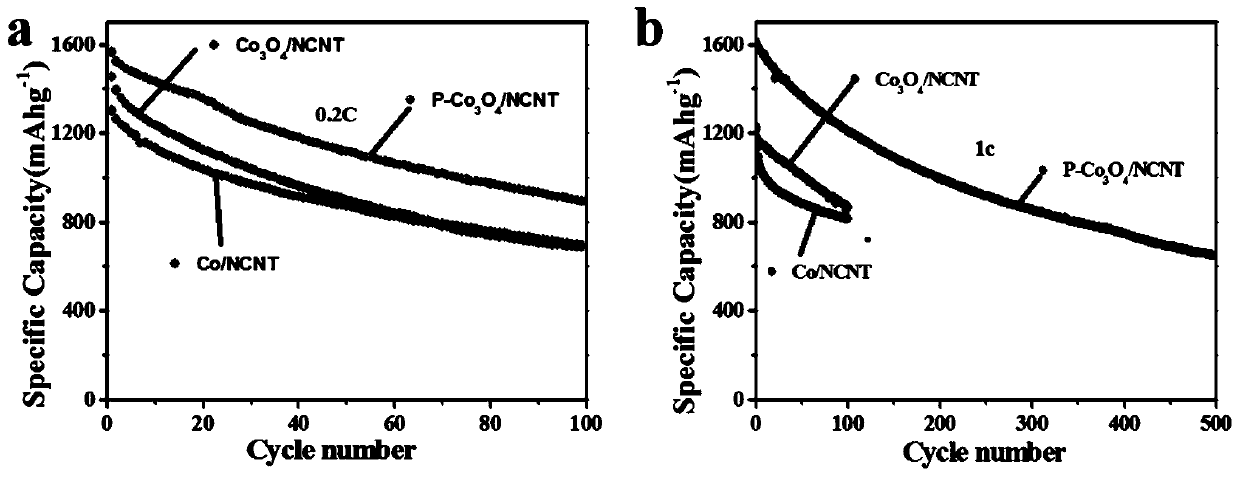

Image

Examples

Embodiment 1

[0032] A method for preparing nitrogen-doped carbon nanotube-supported phosphorus-doped cobalt tetroxide composite material, comprising the following steps:

[0033] (1) Mix water, ethanol and hydrochloric acid to obtain a mixed solution A, wherein the volume ratio of water to ethanol is 1:2, and the concentration of hydrochloric acid is 0.8mol / L, add aniline solution to the mixed solution A, and stir to obtain a mixed solution B, wherein the volume ratio of the aniline solution to the mixed solution A is 1:38; then add carbon nanotubes with a diameter of 50-100 nm to the mixed solution B according to a liquid-solid ratio of 3:1, and stir to obtain a mixture C;

[0034] (2) Adjust the temperature of mixture C in step (1) to 0°C, slowly add ammonium persulfate solution to mixture C, and keep stirring until the solution turns dark blue, indicating that polyaniline is coated on the surface of carbon nanotubes ;

[0035] (3) Add the product obtained in step (2) to 0.5 mol / L exces...

Embodiment 2

[0040] A method for preparing nitrogen-doped carbon nanotube-supported phosphorus-doped cobalt tetroxide composite material, comprising the following steps:

[0041] (1) Mix water, ethanol and hydrochloric acid to obtain a mixed solution A, wherein the volume ratio of water to ethanol is 1:2, and the concentration of hydrochloric acid is 1.0mol / L, add aniline solution to the mixed solution A, and stir evenly to obtain a mixed solution B, wherein the volume ratio of the aniline solution to the mixed solution A is 1:40; then add carbon nanotubes with a diameter of 50-150 nm to the mixed solution B according to a liquid-solid ratio of 4:1, and stir to obtain a mixture C;

[0042] (2) Adjust the temperature of mixture C in step (1) to 5°C, slowly add ammonium persulfate solution to mixture C, and keep stirring until the solution turns dark blue, indicating that polyaniline is coated on the surface of carbon nanotubes ;

[0043] (3) Add the product obtained in step (2) into 0.8mol...

Embodiment 3

[0048] A method for preparing nitrogen-doped carbon nanotube-supported phosphorus-doped cobalt tetroxide composite material, comprising the following steps:

[0049] (1) Mix water, ethanol and hydrochloric acid to obtain a mixed solution A, wherein the volume ratio of water to ethanol is 1:2, and the concentration of hydrochloric acid is 1.2mol / L. Add aniline solution to the mixed solution A, and stir to obtain a mixed solution B, wherein the volume ratio of the aniline solution to the mixed solution A is 1:42; then add carbon nanotubes with a diameter of 50-200nm to the mixed solution B according to a liquid-solid ratio of 4:1, and stir to obtain a mixture C;

[0050] (2) Adjust the temperature of mixture C in step (1) to 10°C, slowly add ammonium persulfate solution to mixture C, and keep stirring until the solution turns dark blue, indicating that polyaniline is coated on the surface of carbon nanotubes ;

[0051] (3) Add the product obtained in step (2) to an excess cobal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com