A method for rapidly melting top-blown furnace knots

A top-blowing furnace and melting furnace technology, applied in electric furnaces, crucible furnaces, rotary drum furnaces, etc., can solve the problems of long time-consuming elimination of furnace knots, increase of slag content, consumption of iron resources, etc., to eliminate hidden dangers of CO explosion and accelerate High-temperature heat conduction and the effect of increasing the temperature of the molten pool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

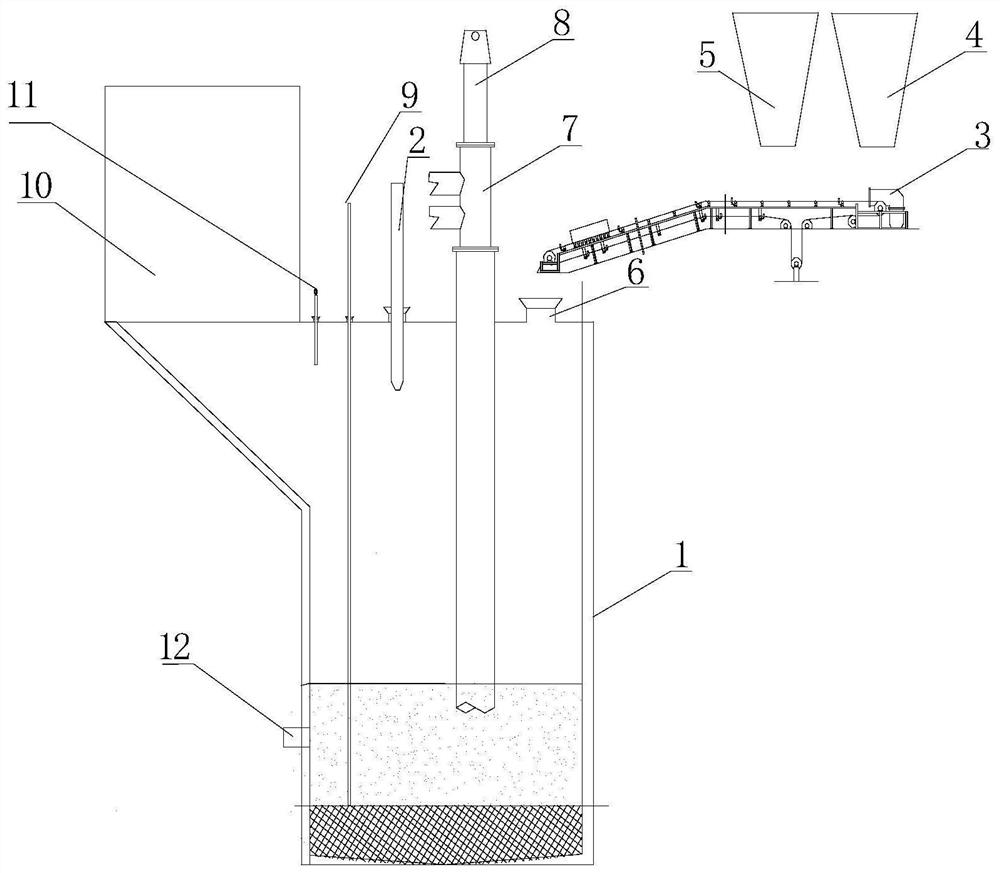

Embodiment 1

[0053] Taking the blister copper blowing process in a Φ5×16m top-blowing furnace as an example, nearly 2,000 mm of high-melting-point junctions are formed in the top-blowing furnace due to process failures, and the content of magnetic iron in the junctions is as high as 45%. The height of the slag outlet of the top-blowing furnace is at 1500mm.

[0054] The method for rapidly melting the top-blown furnace knot, the specific steps are as follows:

[0055] A. Initial melting knot: After finding a large number of high melting point knots in the dead furnace of top-blowing furnace 1, insert the diesel burner 2 from the burner hole on the top of the furnace into the furnace, and insert it into the depth of the top (that is, the spray gun from the top of the top-blowing furnace to The depth of the lower part into the furnace) is 5000mm. Use the residual heat in the furnace to ignite the diesel burner 2, and use the high heat released by the diesel combustion to increase the furnace ...

Embodiment 2

[0060] Taking the Φ4.4×16m top-blowing furnace smelting copper concentrate process as an example, due to the failure to discharge the slag after the shutdown of the furnace, there are still nearly 1500mm of high melting point furnace knots in the top-blowing furnace, and the content of magnetic iron in the furnace knots is as high as 15%. The height of the slag discharge port of the top-blowing furnace is 1800mm.

[0061] The method for rapidly melting the top-blown furnace knot, the specific steps are as follows:

[0062] A. Initial melting furnace junction: put the diesel burner 2 into the furnace from the burner hole, insert it into the furnace roof to a depth of 5000mm, use the residual heat in the furnace to ignite the diesel burner, and use the high heat released by the diesel combustion to increase the furnace temperature, and the diesel burner consumes oil Volume adjusted to 700kg / h, diesel fuel coefficient 10Nm 3 / kg, the fuel excess coefficient is 100%, and the furn...

Embodiment 3

[0067] Taking the process of smelting copper concentrate in a Φ4.4×16m top-blowing furnace as an example, due to a process failure, nearly 1200mm of high-melting-point furnace junctions were formed in the top-blowing furnace, and the content of magnetic iron in the furnace junctions was as high as 25%. The slag discharge port of the top-blowing furnace The height of the location is 1800mm.

[0068] The method for rapidly melting the top-blown furnace knot, the specific steps are as follows:

[0069] A. Initial melting furnace junction: put the diesel burner 2 into the furnace from the burner hole, insert it into the furnace roof to a depth of 5000mm, use the residual heat in the furnace to ignite the diesel burner, and use the high heat released by the diesel combustion to increase the furnace temperature, and the diesel burner consumes oil The volume is adjusted to 750kg / h, and the diesel fuel coefficient is 10Nm 3 / kg, the fuel excess coefficient is 120%, and the furnace pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com