Low-grade fine-grained tin ore biological collecting agent and preparation method and application thereof

A collector, low-grade technology, applied in biochemical equipment and methods, microorganism-based methods, microorganisms, etc., can solve the problems of environmental pollution, large consumption, and low recovery rate of flotation fine particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

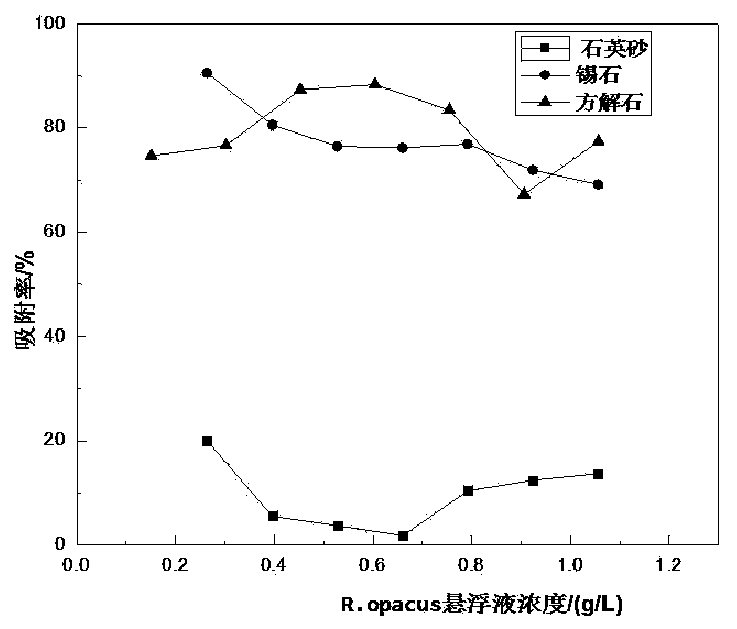

[0042] In the present invention, the source of the Rhodococcus opacus (R. opacus) is not particularly limited, and a conventional source of Rhodococcus opacus well known to those skilled in the art can be used. In the present invention, the concentration of the Rhodococcus opacus in the biological collector is preferably 0.1-0.4 g / L, more preferably 0.3 g / L. The above concentration can ensure that the absorption of cassiterite and quartz sand is relatively smaller when the strains have relatively greater absorption of cassiterite. In the present invention, the preparation method of Rhodococcus turbidity comprises the following steps: inoculate Rhodococcus turbidity into liquid culture medium, culture at 20-40°C, 150-200r / min for 24-96h, 1000-3000r / min Centrifuge for 6-10 minutes, take the supernatant, centrifuge at 8000-12000 r / min for 10-30 minutes, take the precipitate, and obtain the biological collector. In the present invention, described cultivation is more preferably 3...

Embodiment 1

[0056] Culture of Rhodococcus opacus (R.opacus)

[0057] 1. R.opacus medium formula: glucose 10-60g / L, peptone 1-15g / L, yeast extract 2-20g / L, pH value 3.5-6.5.

[0058] 2. Put the medium into the Erlenmeyer flask, wrap it up and put it in an autoclave to sterilize for 25-65 minutes. After cooling down to room temperature, inoculate R.opacus into the medium. The cultivation temperature is respectively 20-40° C., and the rotation speed is 150-200 r / min, and the corresponding cultivation time is 24-96 hours. Centrifuge the cultured bacteria solution at a centrifuge speed of 1000-3000r / min for 6-10min to remove the precipitated substances in the culture solution, and then centrifuge at 8000-12000r / min for 10-30min to obtain wet bacteria mud. Disperse the bacteria sludge with distilled water, then centrifuge under the same conditions, repeat three times, weigh and record to obtain the wet weight of the bacteria, add 1.0-6.5% NaCl to make different concentrations of bacteria susp...

Embodiment 2

[0103] R.opacus has a very good selective adsorption effect on pure cassiterite and quartz sand. When R.opacus is used as a reagent to study the influence of pH on the adsorption rate, change the pH to determine its effect on the adsorption rate of pure quartz sand and refined tin ore. influence, the adsorption rate results of R.opacus on quartz sand and refined tin ore at different pH values are as follows Figure 5 .

[0104] from Figure 5 It can be seen that the influence of pH on the adsorption rate is obvious, and as the pH increases, the adsorption of R. The adsorption rate gradually decreases with the increase of pH. When the pH=2, the adsorption rate is 30%, and when the pH=11, the adsorption rate is almost 0. The higher adsorption rate is due to the fact that R. Caused by cell aggregation under acidic conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com