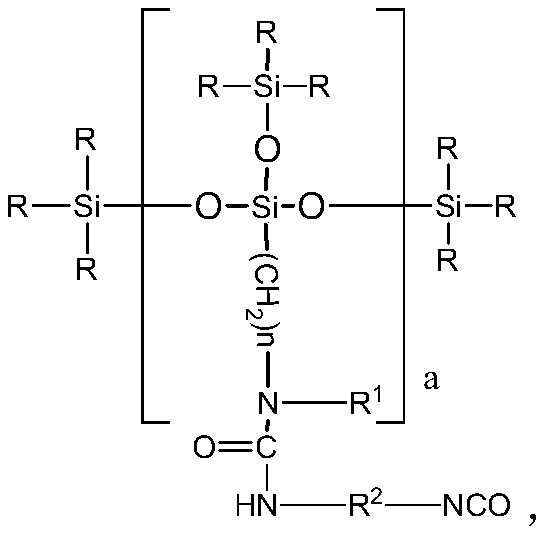

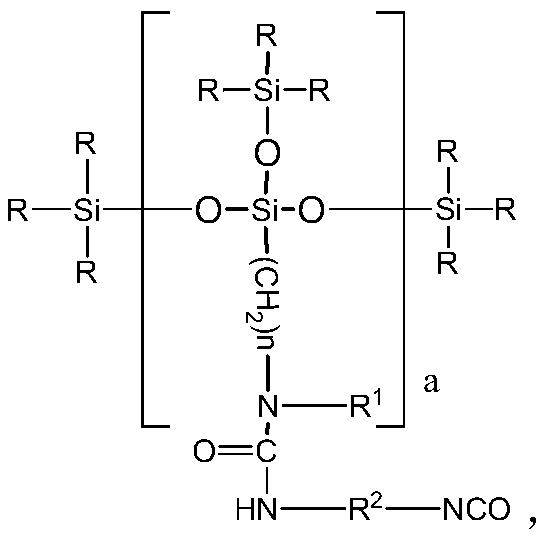

Silane polycondensate modified water dispersible polyisocyanate polymer and preparation method and application thereof

A polyisocyanate and polycondensate technology, applied in the field of coatings, can solve the problems of low isocyanate content, difficulty in large-scale promotion, and no obvious effect of water resistance of water-based coatings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

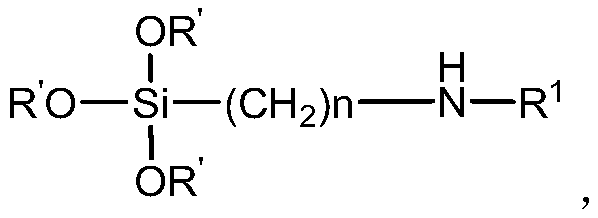

[0065] The preparation method of the water-dispersible polyisocyanate polymer modified by silane polycondensate of the present invention comprises the following steps:

[0066] Under the protection of inert gas, mix 200-300 parts of secondary aminosilane monomer and 400-600 parts of ethanol, heat to 45-85°C, add 40-80 parts of water dropwise under stirring conditions, and drop in 1-3h After completion, stir at 45-85°C for 6-12h, measure the water content by the Karl-Fisher method to monitor the end point of the reaction, stop the reaction when the water content of the reaction system is ≤0.5wt%, and obtain the non-hydrolyzed secondary aminosilane monomer containing color transparent liquid;

[0067] Under the protection of an inert gas, mix 600-1000 parts of the obtained colorless transparent liquid and 350-550 parts of alkoxysilane monomer, heat to 60-120 ° C, distill for 1-12 hours, and monitor the reaction by measuring the hydroxyl value through acetylation At the end poin...

Embodiment 1

[0071] Hydrolysis of secondary aminosilane monomers:

[0072] Introduce nitrogen into the reaction kettle for protection, and add 261.2g of cyclohexylaminopropyltrimethoxysilane and 500g of absolute ethanol at one time, stir evenly, heat to 70°C and keep warm; add deionized water dropwise at a constant speed under stirring conditions 54g, added dropwise within 2h; after the dropwise addition, stirred and reacted at 70°C for 8h, the sample was tested by the Karl-Fisher method to test the moisture content of 0.26wt%, and the reaction was terminated to obtain 815.2g of a colorless transparent liquid, which was sealed and stored ,stand-by.

[0073] Polycondensation of hydrolyzed secondary aminosilane monomers and alkoxysilane monomers:

[0074] Add 815.2 g of the obtained colorless transparent liquid and 416 g of tetraethoxysilane into the reaction kettle in turn, pass through nitrogen protection, gradually raise the temperature to 100 ° C under stirring conditions, and use an oi...

Embodiment 2

[0078] Hydrolysis of secondary aminosilane monomers:

[0079] Put nitrogen into the reaction kettle for protection, and add 287.2g of methylaminoethyltriethoxysilane and 550g of absolute ethanol at one time, stir well, heat to 60°C and keep it warm; add deionized water dropwise at a constant speed under stirring 58g, added dropwise within 2h; after the dropwise addition was completed, stirred and reacted at 60°C for 10h, the sample was tested by Karl Fischer method to have a moisture content of 0.32wt%, and the reaction was terminated to obtain 895.2g of a colorless transparent liquid, which was sealed and stored ,stand-by.

[0080] Polycondensation of hydrolyzed secondary aminosilane monomers and alkoxysilane monomers:

[0081] Add 895.2 g of the obtained colorless transparent liquid and 434 g of trimethoxyethoxysilane into the reaction kettle in turn, pass through nitrogen protection, gradually raise the temperature to 100 ° C under stirring conditions, and use an oil-water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com