Treatment method of silico-calcareous collophanite

A treatment method and collophosite technology, which is applied in the field of waste resource utilization, can solve the problems of difficult processing of middle and low-grade collophosite and low resource utilization rate, and achieve the goals of reducing waste, improving utilization value, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

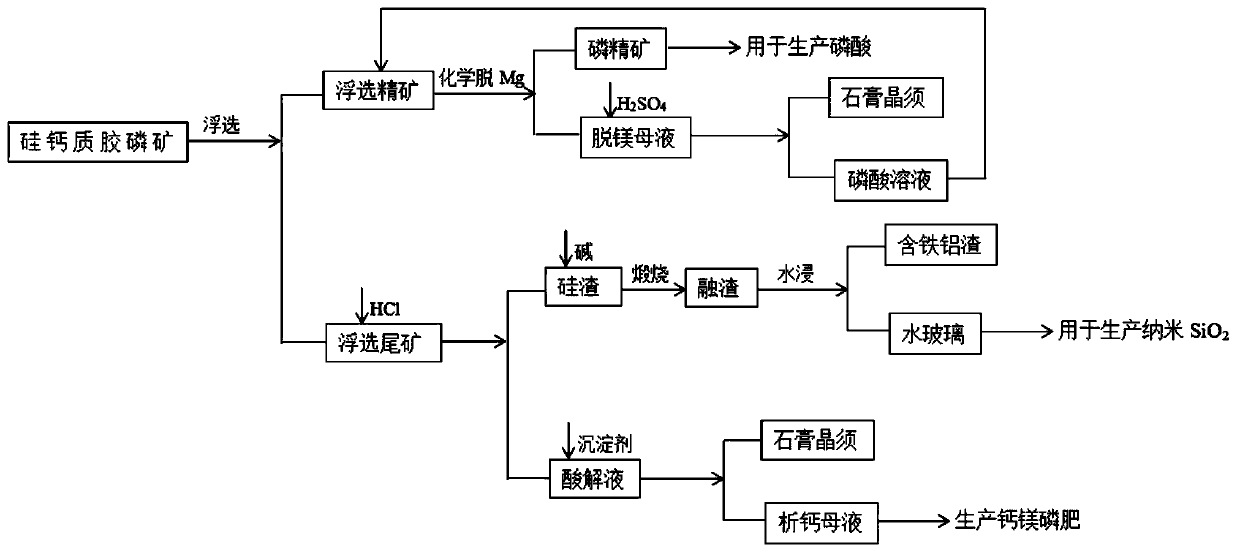

[0039] to combine figure 1 As shown, the processing method of the siliceous calcareous collophosite of the present embodiment specifically comprises the following steps:

[0040] 1) Take 500g of silico-calcareous colloidal phosphate and place it in a flotation machine, add 1160ml of water, stir well, and configure it into a slurry;

[0041] 2) Add 5kg / t of sodium carbonate, 2.3kg / t of sodium silicate, and 1.3kg / t of sulfo fatty acid collector to the pulp in sequence. After the addition is complete, stir for 6 minutes, then ventilate and scrape for 7 minutes to carry out positive Flotation, and subsequently, the concentrate product and tailings product are drained to obtain flotation concentrate and flotation tailings;

[0042] 3) Place the flotation concentrate obtained in step 2) in a 1000ml three-necked flask, heat it to 70°C in an oil bath, slowly add 60ml of 35% phosphoric acid to mix, and after 2.5h of magnesium removal reaction, suction filter to obtain phosphorus concent...

Embodiment 2

[0049] combine figure 1 As shown, the processing method of the siliceous calcareous collophosite of the present embodiment specifically comprises the following steps:

[0050] 1) Take 500g of silicon-calcium colloidal phosphate and place it in the flotation machine, add 1015ml of water, stir well, and configure it into a slurry;

[0051] 2) Add 8.2kg / t of sodium carbonate, 1.5kg / t of sodium silicate, and 2.2kg / t of sulfo fatty acid collector to the pulp in turn. After the addition is complete, stir for 5 minutes, then ventilate and scrape for 9 minutes to carry out Positive flotation, and subsequently, the concentrate product and tailings product are drained to obtain flotation concentrate and flotation tailings;

[0052] 3) Place the flotation concentrate obtained in step 2) in a 1000ml three-necked flask, heat it in an oil bath to 80°C, slowly add 50ml of 42% phosphoric acid to mix, and after 3 hours of demagnesification reaction, suction filter to obtain phosphorous concen...

Embodiment 3

[0059] combine figure 1 As shown, the processing method of the siliceous calcareous collophosite of the present embodiment specifically comprises the following steps:

[0060] 1) Take 500g of silico-calcareous colloidal phosphate and place it in a flotation machine, add 980ml of water, stir well, and configure it into a slurry;

[0061] 2) Add 6.5kg / t of sodium carbonate, 2.5kg / t of sodium silicate, and 3.2kg / t of sulfo fatty acid collector to the pulp in turn. After the addition is complete, stir for 8 minutes, then blow and blow for 10 minutes to carry out After positive flotation, the concentrate product and tailings product are drained to obtain flotation concentrate and flotation tailings.

[0062] 3) Place the flotation concentrate obtained in step 2) in a 1000ml three-necked flask, heat it to 85°C in an oil bath, slowly add 55ml of 41% phosphoric acid to mix, and after 3.5h of magnesium removal reaction, suction filter to obtain phosphorus concentrate and Magnesium mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com