Electrode material for ascorbic acid sensor, biosensor, manufacturing method and application of biosensor

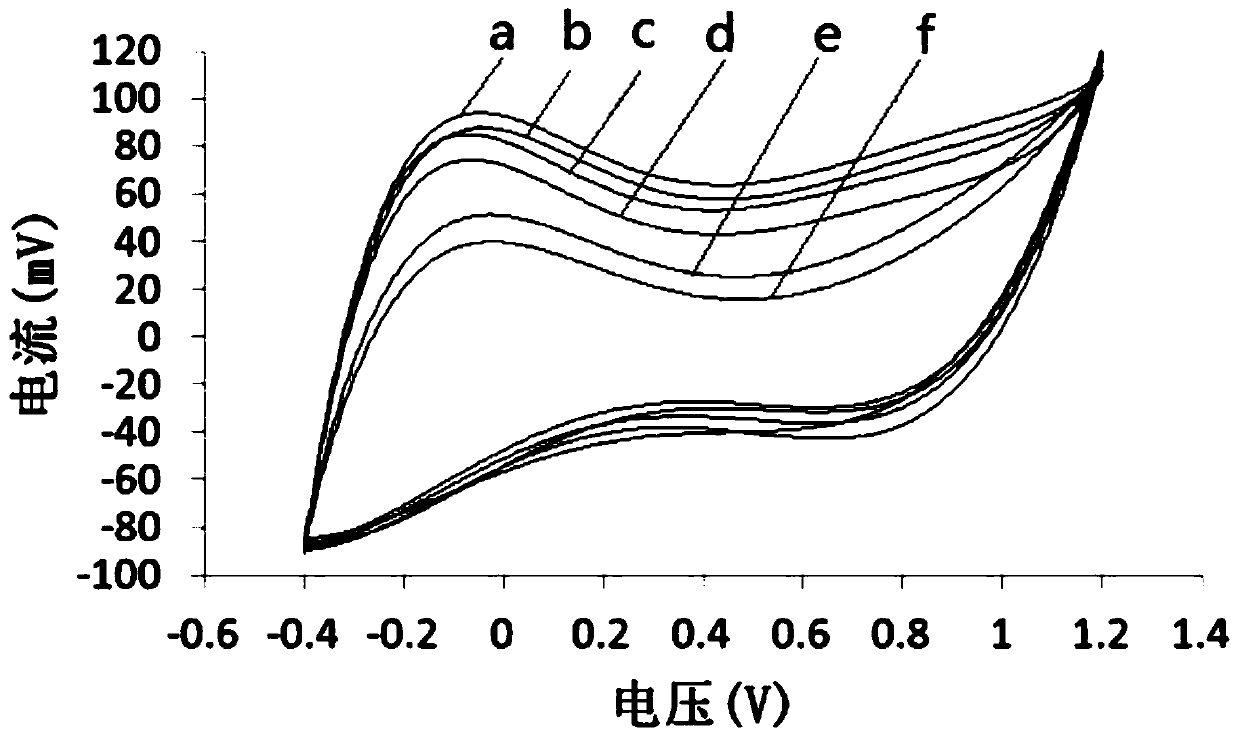

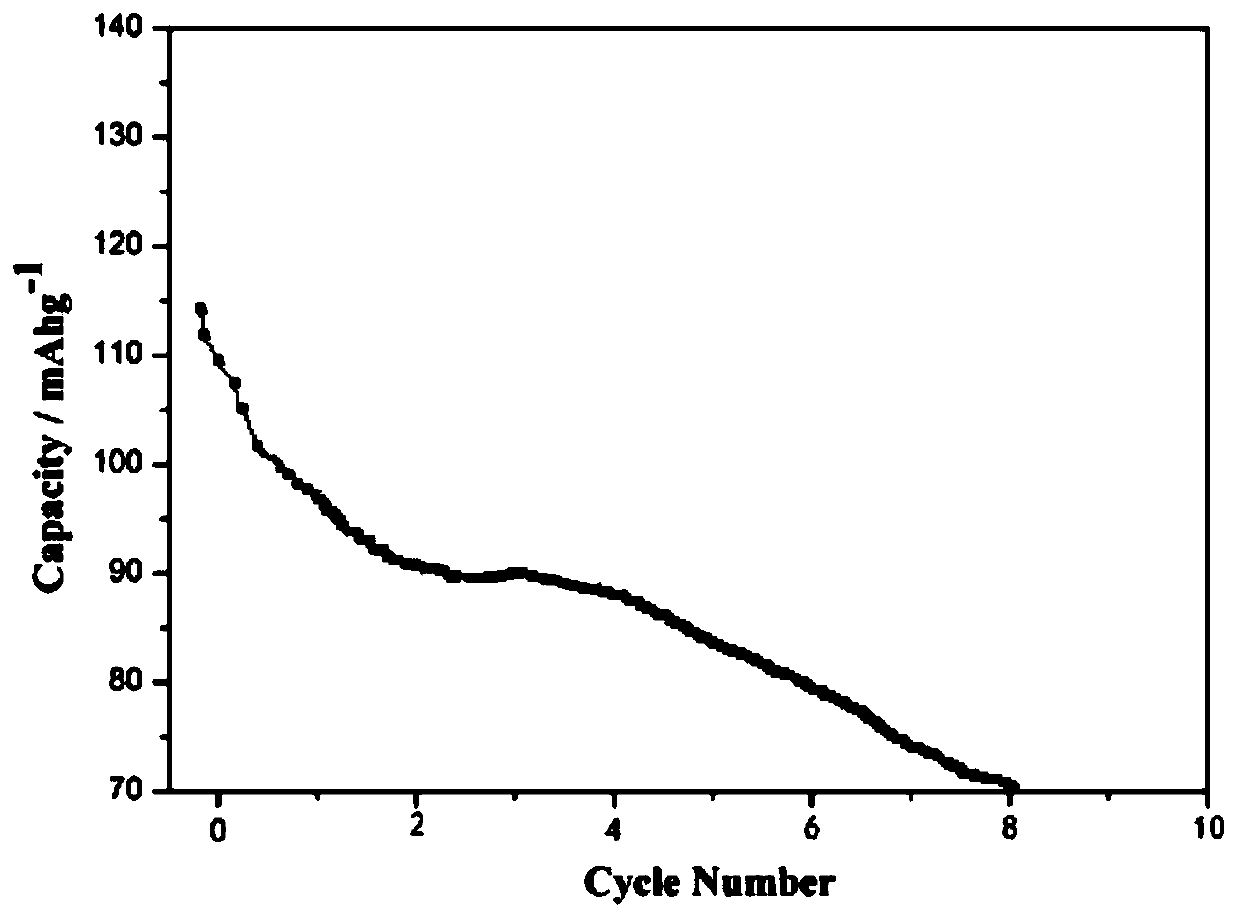

A biosensor and ascorbic acid technology, applied in the field of biosensors, can solve the problems of high experimental conditions, high operating technology, and low detection sensitivity, and achieve excellent electrical properties, high chemical stability, and strong electron transfer capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of preparation method for detecting the electrode material of ascorbic acid, it is characterized in that, comprises the steps:

[0034] (1) Preparation of Ni@NiO composites:

[0035] Cut the nickel foam into 1×5cm 2Soak nickel foam in acetone and sonicate for 6 hours, then immerse foam nickel in 0.1mol / L HCl solution and sonicate for 3 hours, then wash with water for 2 hours and sonicate, and dry at room temperature Until the quality does not change any more, then put the nickel foam and deionized water into the reaction kettle, immerse the nickel foam in the deionized water, first react in the reaction kettle at 100°C for 12h, and then react at 140°C for 12h, After cooling to room temperature, take it out and dry it, and finally sinter it at 300°C for 7 hours, and dry it in vacuum to prepare Ni@NiO composite material;

[0036] (2) Preparation of electrode material for detecting ascorbic acid:

[0037] Disperse 0.04g of carbon nanotubes in concentrated nitric ...

Embodiment 2

[0039] (1) Preparation of Ni@NiO composites:

[0040] Cut the nickel foam into 2×4cm 2 Soak nickel foam in acetone and sonicate for 7 hours, then wash in deionized water and sonicate for 1.5 hours, then immerse foam nickel in 0.1mol / L HCl solution for 4 hours, and finally wash with water for 1.5 hours and sonicate , dry at room temperature until the quality does not change, then put the nickel foam and deionized water into the reactor, soak the nickel foam in the deionized water, react in the reactor at 110°C for 12h, and then at 135°C React at low temperature for 12 hours, take it out and dry after cooling to room temperature, and finally sinter at 350°C for 6 hours, and dry in vacuum to prepare Ni@NiO composite material;

[0041] (2) Preparation of electrode material for detecting ascorbic acid:

[0042] Disperse 0.05g of carbon nanotubes in concentrated nitric acid with a volume fraction of 45%, and reflux at 110°C for 11 hours, cool to room temperature, wash with deioniz...

Embodiment 3

[0044] (1) Preparation of Ni@NiO composites:

[0045] Cut the nickel foam into 3×3cm 2 Soak nickel foam in acetone and sonicate for 8 hours, then wash in deionized water and sonicate for 1 hour, then immerse foam nickel in 0.1mol / L HCl solution for 5 hours, and finally wash with water for 1 hour and sonicate, at room temperature Dry under high temperature until the quality does not change anymore, then put nickel foam and deionized water into the reactor, immerse the nickel foam in deionized water, react in the reactor at 120°C for 12 hours, and then react at 130°C After cooling to room temperature for 12 hours, take it out and dry it, and finally sinter it at 400°C for 5 hours and dry it in vacuum to prepare Ni@NiO composite material;

[0046] (2) Preparation of electrode material for detecting ascorbic acid:

[0047] Disperse 0.06g of carbon nanotubes in concentrated nitric acid with a volume fraction of 45%, and reflux at 120°C for 10h, cool to room temperature, wash with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com