Metal phosphide and heteroatom doped porous carbon composite material as well as preparation and application thereof

A metal phosphide and composite material technology, applied in the direction of carbon compounds, non-metallic elements, chemical instruments and methods, etc., can solve the problems of harsh conditions, high raw material costs, complicated process, etc., achieve good performance, simple preparation method, and relatively The effect of large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

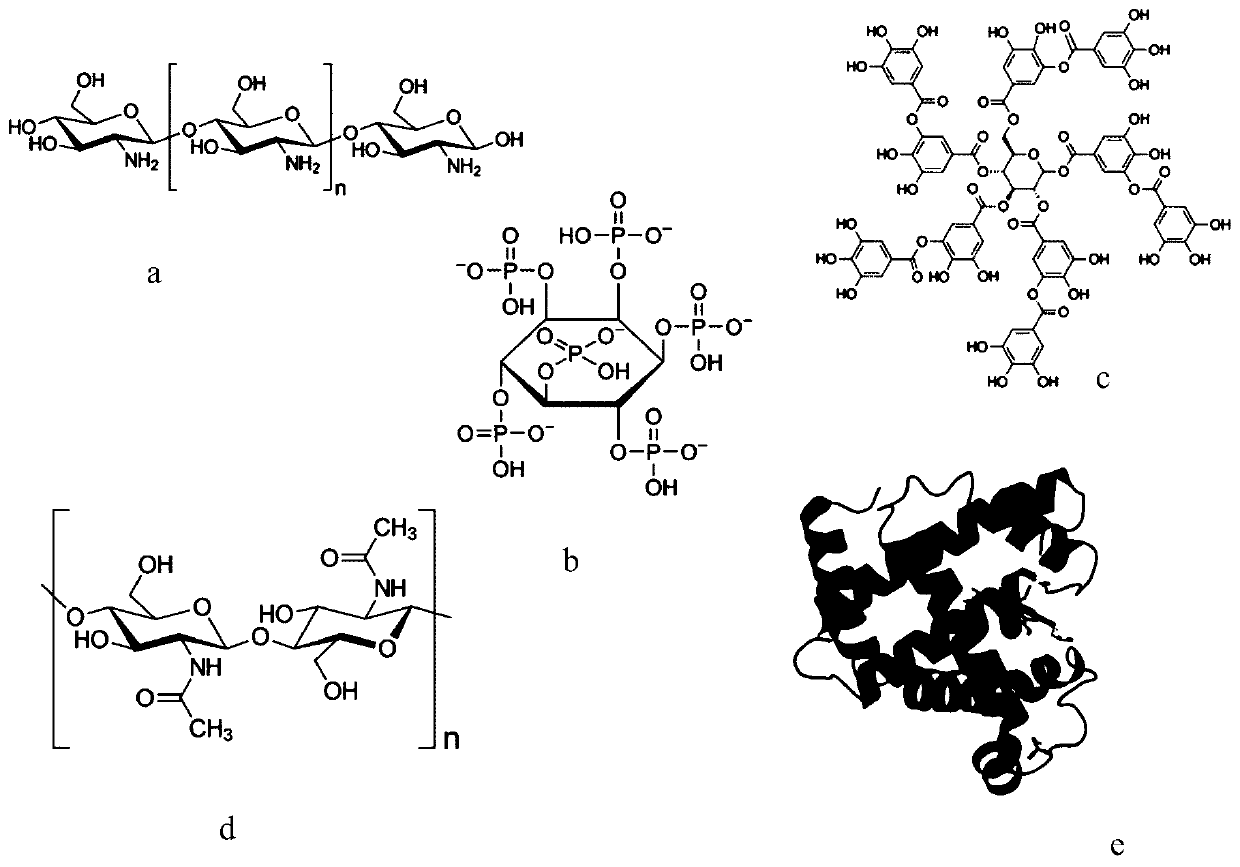

[0040] Put 6.00g phytic acid into a 100mL flat-bottomed glass cup, add 1mmol copper acetate, 20mL ultrapure water, stir on a magnetic stirrer for 2min, then add 2.0g chitin, stir for 12h and mix well, then freeze in a freeze dryer After drying for 1 day, a fluffy, sticky, light blue block solid was obtained. Put the obtained solid into a quartz boat, use a tube furnace, under a nitrogen atmosphere, at a heating rate of 5°C / min, and keep it at 900°C for 3h. After the reaction is finished, it will be cooled to room temperature, and a black solid is obtained, which is metallic phosphorus. Compounds and heteroatoms (nitrogen, phosphorus) co-doped porous carbon composite materials.

[0041] Performance characterization

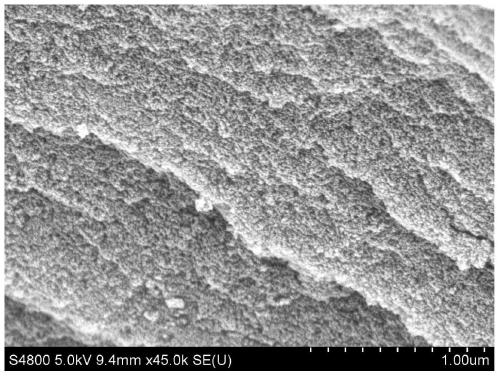

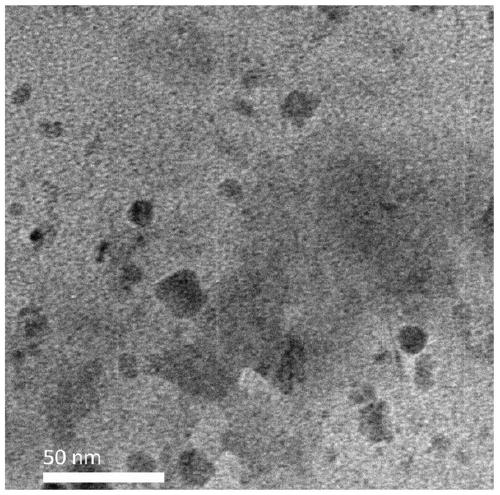

[0042] The morphology and structure of the metal phosphide and porous carbon composite material obtained in Example 1 are shown in figure 2 with image 3 ,by figure 2 It can be seen that the morphology of the material is the morphology of particle accumulation, imag...

Embodiment 2

[0045] Put 6.00 g phytic acid into a 100 mL flat-bottom glass cup, add 1 mmol copper acetate, 20 mL ultrapure water, stir on a magnetic stirrer for 2 minutes, then add 2.0 g chitin and stir for 12 hours to mix well. The obtained mixture was vacuum-dried for 1 day to obtain a fluffy, sticky, slightly blue block solid. Put the obtained solid in a quartz boat, use a tube furnace, in a nitrogen atmosphere, heat up to 800°C at a heating rate of 5°C / min for 3 hours, and after the reaction is finished and lower to room temperature, a black solid is obtained.

Embodiment 3

[0047] Put 6.00 g phytic acid into a 100 mL flat-bottom glass cup, add 1 mmol copper acetate, 20 mL ultrapure water, stir on a magnetic stirrer for 2 minutes, then add 2.0 g chitin and stir for 12 hours to mix well. The obtained mixture was first put into liquid nitrogen to pre-freeze for 20 minutes, and then put into a freeze dryer under negative pressure to freeze-dry for 1 day to obtain a fluffy, sticky, light blue blocky solid. Put the obtained solid into a quartz boat, use a tube furnace, in a nitrogen atmosphere, heat up to 700°C at a heating rate of 5°C / min, and hold for 3 hours. After the reaction is finished, the black solid is obtained and it is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com