A kind of photocatalytic thin film based on titanium nitride and titanium oxide and preparation method thereof

A photocatalytic thin film, titanium oxide technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of low production efficiency, complex equipment, unfavorable industrial application, etc., and achieve the improvement effect. , narrow the forbidden band width, improve the effect of photocatalysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

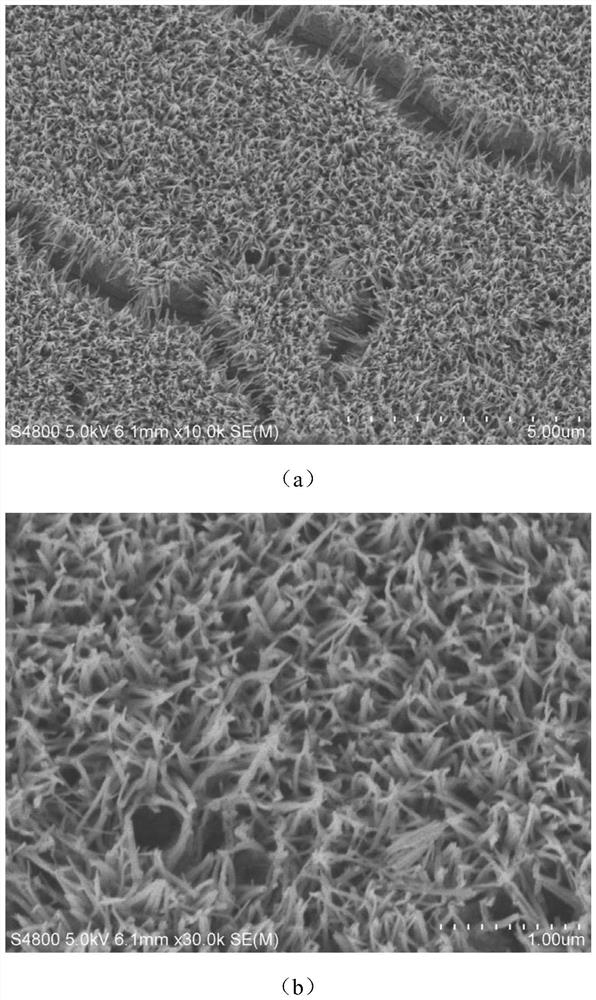

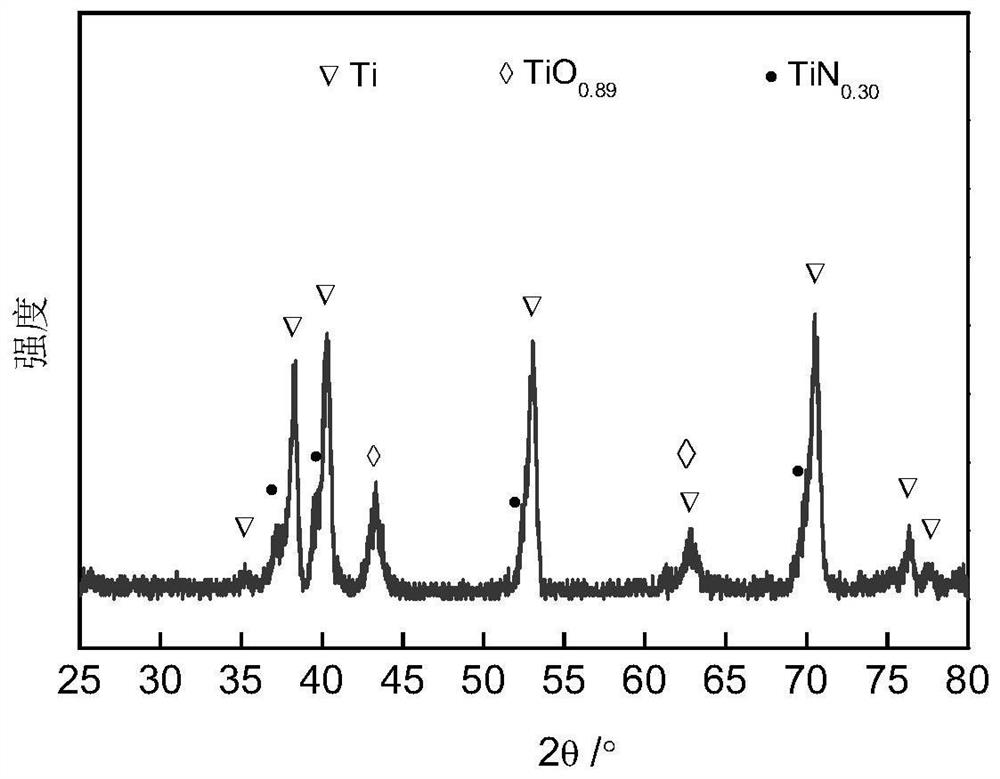

[0028] Step 1. Make the area 5×5cm 2 Immerse the cleaned titanium sheet in 50mL of hydrogen peroxide solution with a mass concentration of 6%, add 1mL of nitric acid with a mass fraction of 0.05% and 10mg of melamine at the same time, react at 80°C for 72 hours, take it out and dry it completely after cleaning, and dry it at 400 ℃ air atmosphere heat treatment for 3 hours, obtained on the titanium substrate growth TiO 2 Thin films of nanowire arrays;

[0029] Step 2, loading TiO on the titanium sheet 2 The samples of nanowires were heat-treated at 750°C for 3 hours in an ammonia atmosphere with a flow rate of 100mL / min to obtain TiN 0.3 / TiO 0.89 One-dimensional nanowire films;

[0030] Step 3: Add 100 mL of deionized water, 1.75 g of glycine, 0.6 mL of 63% nitric acid and 1.25 g of titanyl sulfate into the porcelain crucible. The crucible was transferred to a heat treatment furnace at 400°C for solution combustion reaction to obtain a fluffy black powder. Add 0.5g of bl...

Embodiment 2

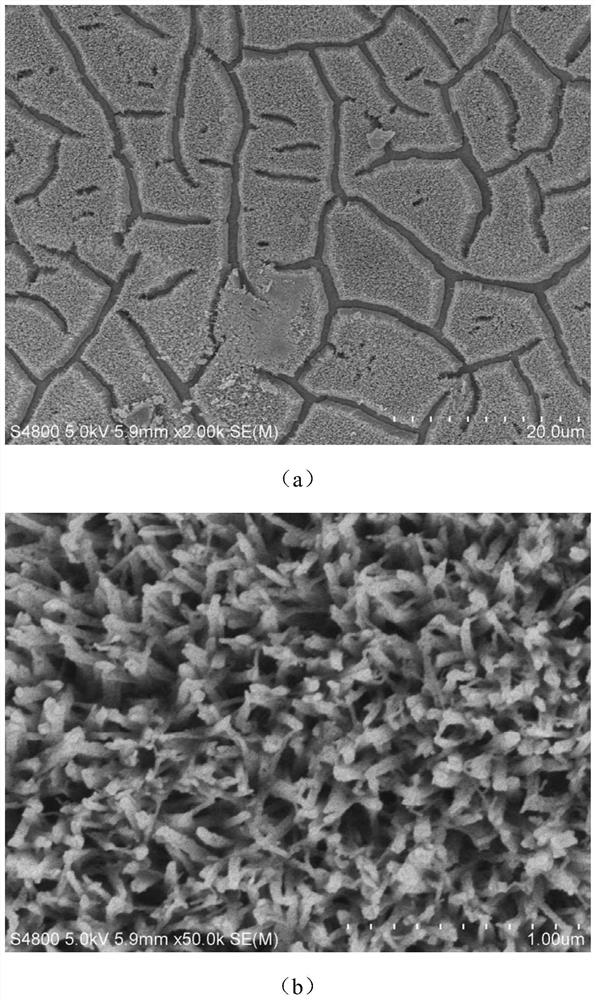

[0034] Step 1. Make the area 5×5cm 2Immerse the cleaned titanium sheet in 50mL of hydrogen peroxide solution with a mass concentration of 30%, add 1mL of nitric acid with a mass fraction of 5% and 100mg of melamine at the same time, react at 80°C for 72 hours, take it out and dry it completely after cleaning, and dry it at 550 ℃ air atmosphere heat treatment for 3 hours, obtained on the titanium substrate growth TiO 2 Thin films of nanowire arrays;

[0035] Step 2, loading TiO on the titanium sheet 2 The samples of nanowires were heat-treated at 900°C for 3 hours in an ammonia atmosphere with a flow rate of 100mL / min to obtain TiN 0.3 / TiO 0.89 One-dimensional nanowire films;

[0036] Step 3: Add 100 mL of deionized water, 1.75 g of glycine, 0.6 mL of 63% nitric acid and 1.25 g of titanyl sulfate into the porcelain crucible. The crucible was transferred to a heat treatment furnace at 400°C for solution combustion reaction to obtain a fluffy black powder. Add 1g of black ...

Embodiment 3

[0040] Step 1. Make the area 5×5cm 2 Immerse the cleaned titanium sheet in 50mL of hydrogen peroxide solution with a mass concentration of 20%, add 1mL of nitric acid with a mass fraction of 2.5% and 100mg of melamine at the same time, react at 80°C for 72 hours, take it out and clean it, dry it completely, and dry it at 550 ℃ air atmosphere heat treatment for 3 hours, obtained on the titanium substrate growth TiO 2 Thin films of nanowire arrays;

[0041] Step 2, loading TiO on the titanium sheet 2 The samples of nanowires were heat-treated at 800°C for 2 hours in an ammonia atmosphere with a flow rate of 100mL / min to obtain TiN 0.3 / TiO 0.89 One-dimensional nanowire films;

[0042] Step 3: Add 100 mL of deionized water, 1.75 g of glycine, 0.6 mL of 63% nitric acid and 1.25 g of titanyl sulfate into the porcelain crucible. The crucible was transferred to a heat treatment furnace at 400°C for solution combustion reaction to obtain a fluffy black powder. Add 0.5g of black ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com