Non-toxic environment-friendly water-based paint and preparation method thereof

A water-based coating, non-toxic and environmentally friendly technology, used in antifouling/underwater coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc. It can solve problems such as poor mechanical quality, poor life and stability, and achieve excellent mechanical quality. , long service life, simple ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

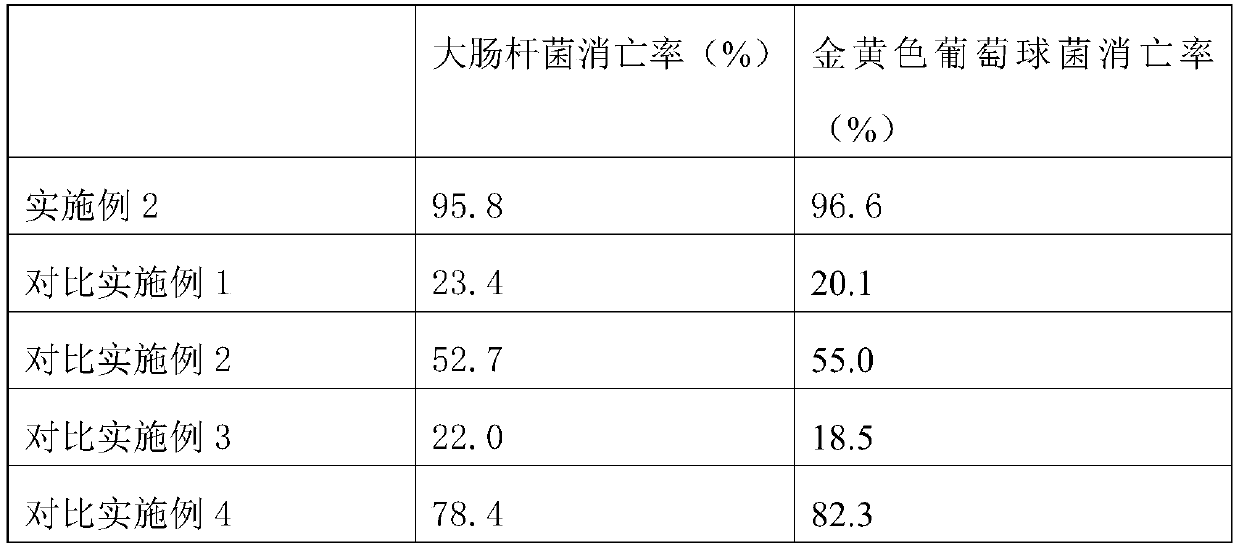

Examples

preparation example Construction

[0023] The preparation method of described reinforcing additive comprises the steps:

[0024] 1) Put the montmorillonite into the calcination furnace for high-temperature calcination treatment, keep the temperature in the calcination furnace at 850-880°C during the process, take it out after 35-40 minutes of treatment;

[0025] 2) Put the montmorillonite treated in step 1) into a citric acid solution with a mass fraction of 0.2%, soak it for 5-8 minutes, filter it out, wash it with deionized water until it is neutral, and set it aside;

[0026] 3) Put the montmorillonite treated in step 2) into the composite treatment solution, continuously stir and soak for 1 to 1.5 hours, filter out, and then dry to constant weight; the composite treatment solution is as follows: Material composition in parts by weight: 15-20 parts of nano-titanium dioxide, 5-8 parts of meteorite powder, 10-15 parts of silane coupling agent, 6-8 parts of dodecyltrimethylammonium bromide, 8-12 parts of chitos...

Embodiment 1

[0032] A non-toxic and environmentally friendly water-based paint, made of the following substances in corresponding parts by weight: 50 parts of polyurethane emulsion, 14 parts of acrylate emulsion, 2 parts of defoamer, 2 parts of surfactant, 1 part of leveling agent, film-forming agent 1.5 parts of auxiliary agent, 3 parts of thickener, 4 parts of reinforcing additive, 0.5 part of antioxidant, 0.1 part of ultraviolet absorber, 35 parts of deionized water; the described defoamer is a silicone defoamer; the described The surfactant is sodium dodecylbenzenesulfonate; the leveling agent is carboxymethyl cellulose, and the film-forming aid is dipropylene glycol butyl ether; the thickener is TT935.

[0033] The preparation method of described reinforcing additive comprises the steps:

[0034] 1) Put the montmorillonite into the calcination furnace for high-temperature calcination treatment, keep the temperature in the calcination furnace at 850°C during the process, and take it ou...

Embodiment 2

[0042] A non-toxic and environmentally friendly water-based paint, made of the following substances in corresponding parts by weight: 56 parts of polyurethane emulsion, 14 parts of acrylate emulsion, 2 parts of defoamer, 3.5 parts of surfactant, 1.5 parts of leveling agent, film-forming agent 2 parts of auxiliary agent, 4.5 parts of thickener, 6 parts of reinforcing additive, 1 part of antioxidant, 0.2 part of ultraviolet absorber, 40 parts of deionized water; the described defoamer is a silicone compound; the described surface The active agent is sodium dodecylbenzenesulfonate; the leveling agent is carboxymethyl cellulose, and the film-forming aid is dipropylene glycol butyl ether; the thickener is hydroxyethyl cellulose .

[0043] The preparation method of described reinforcing additive comprises the steps:

[0044] 1) Put the montmorillonite into the calcination furnace for high-temperature calcination treatment, keep the temperature in the calcination furnace at 870°C du...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap