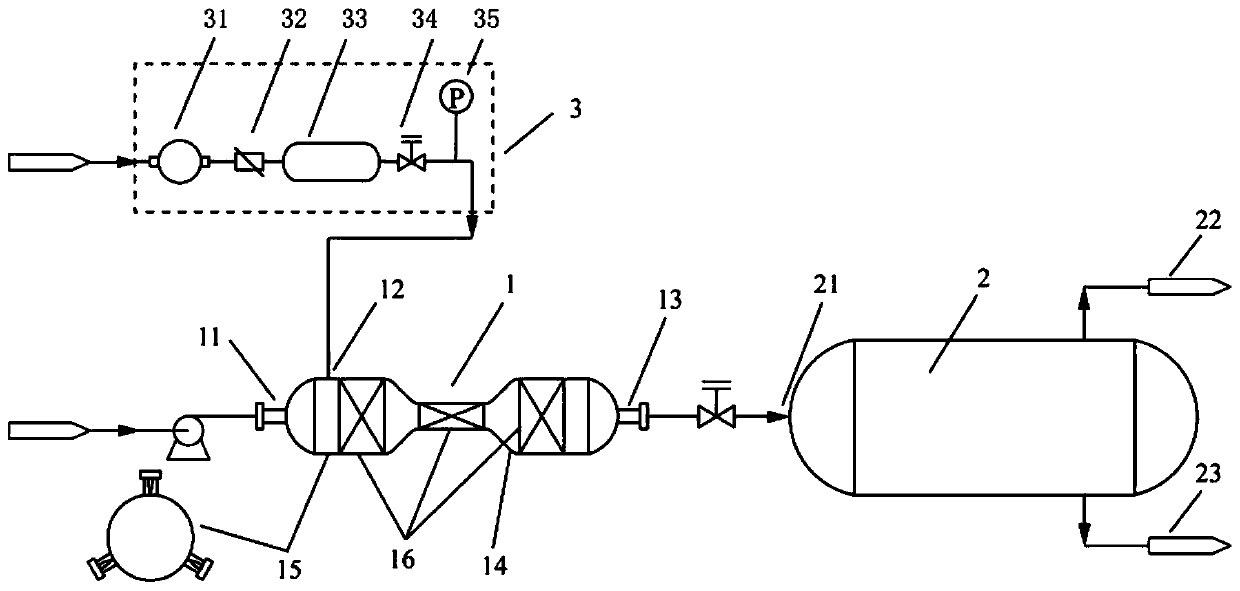

Method for dehydrating highly emulsified sump oil and device adopted by method

A technology for slop oil and oil-water mixture, which is used in chemical dehydration/demulsification, petroleum industry, treatment of hydrocarbon oil, etc. It can solve the problems of long residence time, poor adaptability of raw materials, limited effect, etc. The effect of low milk temperature and fast water output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] A refinery in Wuhan adopts the method and device of the present invention to dehydrate the waste oil after water cutting in the atmospheric storage tank.

[0067] 1. Experimental conditions

[0068] Material: Water-containing dirty oil (water content is about 42%). Its main components are engine oil, lubricating oil and water. The dirty oil is seriously emulsified and generally exists in the form of W / O at room temperature. The density is 925Kg / m 3 , The demulsifier adopts a new demulsifier.

[0069] The preparation method of demulsifier comprises the following steps:

[0070] In the first step, add 6g of tetraethylenepentamine and 10g of basic catalyst (sodium hydroxide) to the high-temperature reactor, seal the reactor, purge and replace with nitrogen, and then evacuate, repeat the operation at least twice, start stirring and Stop heating when the temperature rises to 130°C, open the feed valve, add 255g of propylene oxide, control the reaction temperature not to e...

Embodiment 2

[0082] A chemical plant in Hainan adopts the method and device of the present invention to dehydrate a large amount of water-containing waste oil produced during offshore oil and gas field exploitation and chemical production.

[0083] 1. Experimental conditions

[0084] Material: water-containing dirty oil (water content is about 46%), mainly composed of crude oil, lubricating oil, sediment and water, the dirty oil is seriously emulsified, and generally exists in the form of O / W / O emulsion at room temperature . The density is 946Kg / m 3 , The demulsifier adopts a new demulsifier.

[0085] The preparation method of demulsifier comprises the following steps:

[0086] In the first step, 8 g of tetraethylenepentamine and 15 g of basic catalyst (sodium hydroxide) are added to the high-temperature reactor, the reactor is sealed, purged and replaced with nitrogen, and then vacuumized. This operation is repeated at least twice, and stirring is started and Stop heating when the tem...

Embodiment 3

[0098] An oil refinery in Daqing adopts the method and device of the present invention to dehydrate a large amount of heavily emulsified water-containing dirty oil produced during oil field development.

[0099] 1. Experimental conditions

[0100] Material: water-containing dirty oil (water content is about 48%), which is mainly composed of crude oil, organic sludge, surface active substances and water. The dirty oil is seriously emulsified and generally exists in the form of W / O at room temperature. The density is 967Kg / m 3 , The demulsifier adopts a new demulsifier.

[0101] The preparation method of demulsifier comprises the following steps:

[0102] In the first step, add 10 g of tetraethylenepentamine and 20 g of basic catalyst (sodium hydroxide) to the high-temperature reactor, seal the reactor, purge and replace with nitrogen, and then evacuate, repeat the operation at least twice, start stirring and Stop heating when the temperature rises to 130°C, open the feed val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com