Integrated microfluidic electrochemical sensor chip for rapid BOD detection, and preparation method and BOD detection method thereof

A sensor chip and electrochemical technology, applied in chemical instruments and methods, laboratory containers, electrochemical variables of materials, etc., can solve problems such as inability to realize continuous online monitoring of BOD, large volume, and limited efficiency of microbial degradation of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] The present invention provides a method for preparing an integrated microfluidic electrochemical sensor chip described in the above scheme, comprising the following steps:

[0073] (1) Insulate both sides of the single crystal silicon substrate, apply a positive photoresist on the surface of the insulated single crystal silicon substrate, and construct a three-electrode gold interdigitated ultramicroelectrode array on the surface of the insulated single crystal silicon substrate;

[0074] Form the bottom surface of the single-crystal silicon substrate of the three-electrode gold interdigitated ultramicroelectrode array with a positive photoresist, and then build a platinum thin-film temperature sensor on the bottom surface of the insulated single-crystal silicon. Surface-attached miniature heating copper electrodes;

[0075] (2) Throw a negative photoresist on the surface of the quartz glass sheet, and use photolithography to engrave the microfluidic channel system patt...

Embodiment 1

[0115] Preparation of integrated microfluidic electrochemical sensor chip:

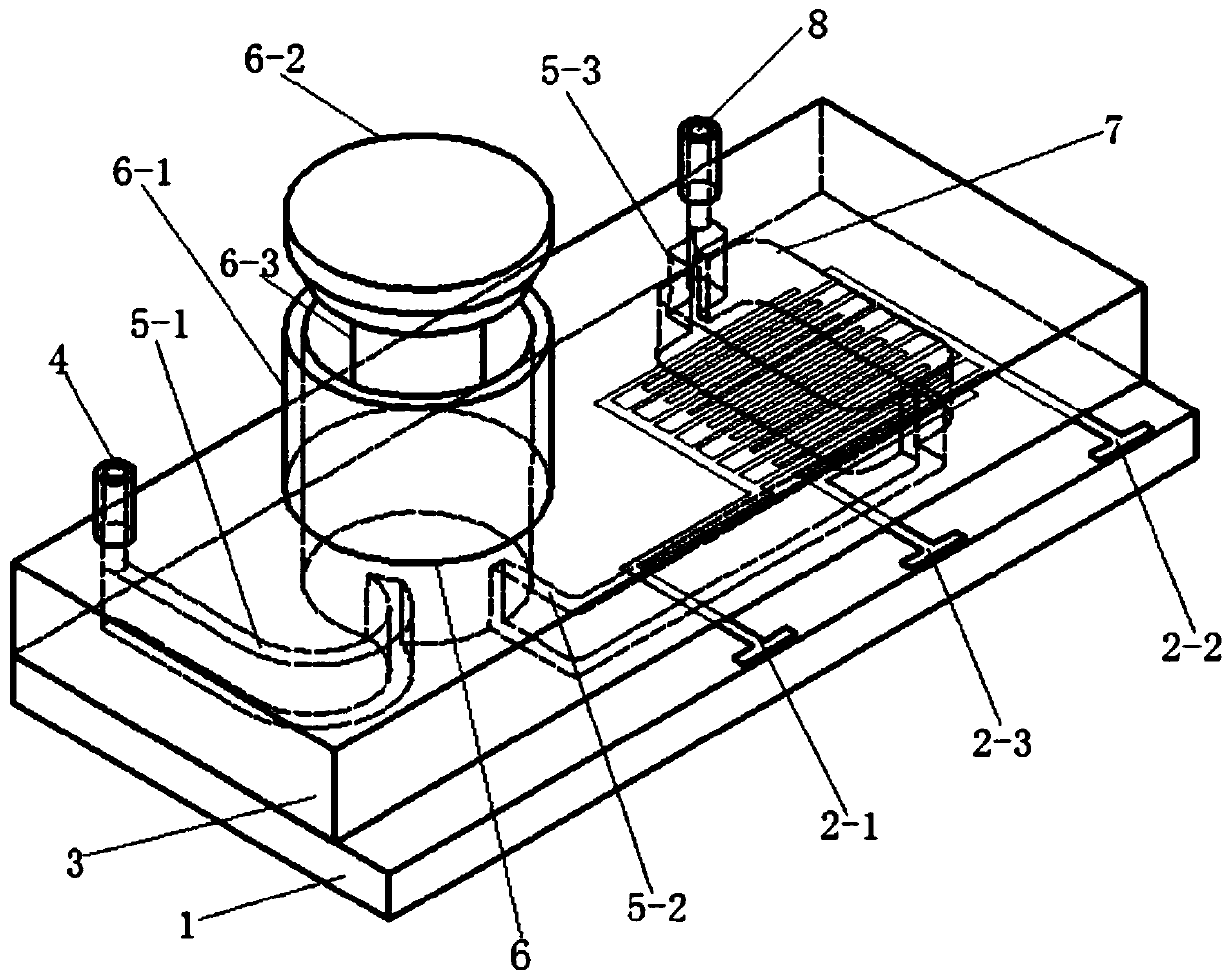

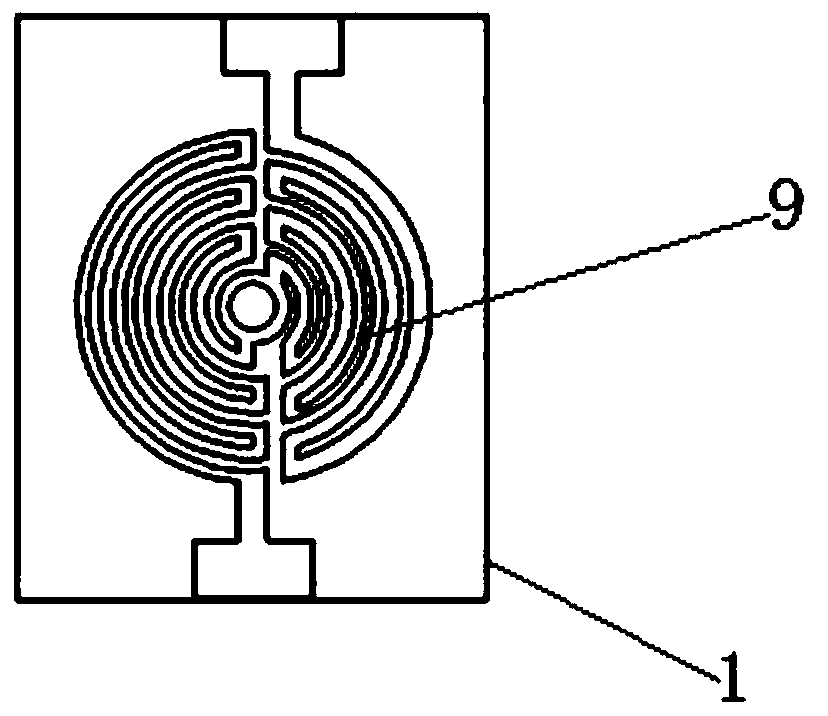

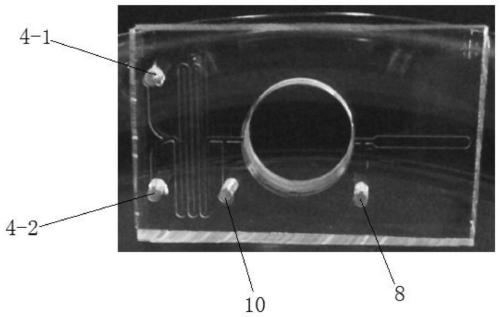

[0116] The schematic diagram of the integrated microfluidic electrochemical sensor chip is shown in figure 1 with figure 2 As shown, the actual picture is as Figure 7 As shown, including a single crystal silicon substrate 1;

[0117]The PDMS layer 3 superimposed on the surface of the monocrystalline silicon substrate 1 (thickness is 270 μm); the inside of the PDMS layer 3 is provided with a microfluidic channel system, and the microfluidic channel system includes the inlet 4 of the liquid to be tested (divided into the liquid inlet 4-1 and the test liquid inlet 4-2), the biofilm reactor 6 (in the to-be An air injection port 10) is arranged between the inlet of the measuring liquid and the biofilm reactor, the electrochemical detection cell 7 communicating with the outlet of the inlet and the biofilm reactor through the second microflow channel 5-2, and the electrochemical detection cell 7 communi...

Embodiment 2

[0135] The integrated microfluidic electrochemical sensor chip packaged in Example 1 is used to measure the biochemical oxygen demand (BOD) of the water sample:

[0136] (1) Preparation of solution: Dilute 100mg / L BOD standard solution with 5mM PBS (pH 7.0) to prepare BOD standard solutions of different concentrations (4mg / L, 20mg / L, 40mg / L, 60mg / L and 80mg / L) , and then mixed 40mM potassium ferricyanide (formed in 5mM PBS (pH 7.0)) solution respectively, and finally prepared into BOD sample solutions of different concentrations containing 20mM potassium ferricyanide (2mg / L, 10mg / L, 20mg / L, 30mg / L and 40mg / L);

[0137] (2) Inject solution: open the liquid to be tested inlet 4-1, the liquid to be tested inlet 4-2 and the air injection port 10, close the waste liquid outlet 8, and the standard solution is simultaneously injected by the liquid to be tested inlet 4-1, the liquid to be tested Inject into the inlet 4-2 until the biofilm reactor is full of solution, close the inlet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com