Insulating ring for microwave magnetron and preparation method of the insulating ring

An insulating ring and magnetron technology, applied in the field of metallized ceramic processing, can solve the problem of easy oxidation of aluminum nitride ceramics, and achieve the effects of improving tensile strength, surface quality and overall performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The insulating ring for the microwave magnetron of the present embodiment comprises a ring-shaped ceramic substrate and a metallized layer, and the preparation method of the metallized layer comprises the following steps:

[0048] A1: Prepare mixed metal powder; put 8 parts by weight of titanium powder, 3 parts of aluminum powder, 60 parts of copper powder and 10 parts of clay particles into a drying furnace for drying, and then perform ball milling. The frequency of the ball mill is 20 Hz, and the ball milling time is 15h; after ball milling, separate with filter screen to obtain mixed metal powder;

[0049] A2: Prepare metallization paste; add 1 part of binder to the metal mixed powder obtained in step A1, and the binder is mixed according to the weight ratio of terpineol: polyvinyl alcohol = 2:1; mix evenly to obtain metal ointment;

[0050] A3: Configuration of fluxing agent: 0.5 part of fluxing agent NaF, K 2 ZrF 6 70 parts, 0.01 part of cerium chloride, 0.01 p...

Embodiment 2

[0067] The insulating ring for the microwave magnetron of the present embodiment comprises a ring-shaped ceramic substrate and a metallized layer, and the preparation method of the metallized layer comprises the following steps:

[0068] A1: Preparation of mixed metal powder; 20 parts by weight of titanium powder, 5 parts of aluminum powder, 70 parts of copper powder and 20 parts of clay particles were placed in a drying furnace for drying, and then ball milled. The frequency of the ball mill was 30 Hz, and the ball milling time was 25h; after ball milling, separate with filter screen to obtain mixed metal powder;

[0069] A2: Prepare metallization paste; add 3 parts of binder to the metal mixed powder obtained in step A1, and the binder is mixed with polyvinyl alcohol = 2:3 by weight; then mix evenly to obtain metallization paste;

[0070]A3: Configuration of plating flux: 1.5 parts of NaF, K 2 ZrF 6 120 parts, 0.1 part of cerium chloride, 0.1 part of lanthanum chloride an...

Embodiment 3

[0087] The insulating ring for the microwave magnetron of the present embodiment comprises a ring-shaped ceramic substrate and a metallized layer, and the preparation method of the metallized layer comprises the following steps:

[0088] A1: Preparation of mixed metal powder; 14 parts by weight of titanium powder, 4 parts of aluminum powder, 65 parts of copper powder and 15 parts of clay particles were placed in a drying furnace for drying, and then ball milled. The frequency of the ball mill was 25 Hz, and the ball milling time was 20h; after ball milling, separate with filter screen to obtain mixed metal powder;

[0089] A2: Prepare metallization paste; add 2 parts of binder to the metal mixed powder obtained in step A1, and the binder is mixed according to the weight ratio of terpineol: polyvinyl alcohol = 2:2.5; mix evenly to obtain metallization paste;

[0090] A3: The configuration of the plating flux: the flux consists of 1 part of NaF, K 2 ZrF 6 90 parts, 0.05 part...

PUM

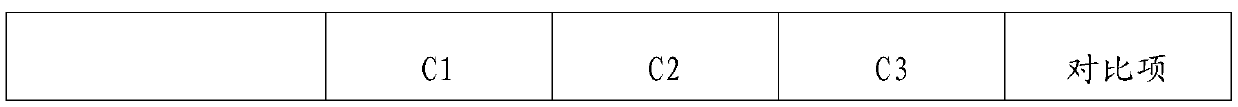

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com