Carborane-containing adhesive resin with resistance to high and low temperature and preparation method thereof

A technology of high and low temperature resistance, adhesives, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of harsh conditions, high synthesis difficulty, limited funds and experimental conditions, etc. performance, achieve controllability, achieve the effect of bond strength and high and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Add 1 mol of trimethylolpropane to 20 ml of ethyl acetate and stir to dissolve, remove water under reduced pressure at 20°C for 10 min, and then store under argon atmosphere;

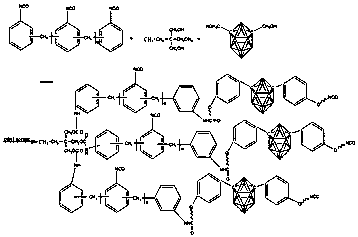

[0024] 2) Preparation of isocyanate-terminated carborane prepolymer (component A): under argon atmosphere, stir 0.32 mol of PAPI and 5 ml of ethyl acetate at 10°C, heat up to 60°C, add in batches after dehydration The trimethylolpropane-butyl acetate and 1,7-dimethylolcarborane-ethyl acetate took 20 minutes; then the temperature was raised to 70°C for 0.5 hours, and the isocyanate content was measured. After completion, it was cooled to room temperature and released material;

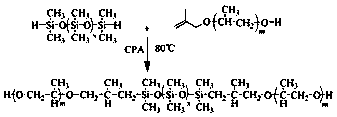

[0025] 3) Preparation of hydroxyl-terminated ABA-type silicone-containing polyether polyol (component B): polydimethylsiloxane and methallyl polyether are added to the tetrahydrochloride with N2 at a molar ratio of 1:0.5 In a flask, heat to 10°C. Add 0.5 ppm of chloroplatinic acid with a syringe, observe the temperatu...

Embodiment 2

[0028] 1) Trimethylolpropane dehydration: first add 1 mol trimethylolpropane into 110 ml ethyl acetate and stir to dissolve, remove water under reduced pressure at 50°C for 35 minutes, and then store under argon atmosphere;

[0029] 2) Preparation of isocyanate-terminated carborane prepolymer (component A): under argon atmosphere, stir 0.32mol PAPI and 30ml ethyl acetate at 35°C, heat up to 65°C, add dehydrated Trimethylolpropane-butyl acetate, 1,7-dimethylolcarborane-ethyl acetate, take 70min; then heat up to 85°C for 3 hours, measure isocyanate content, cool to room temperature after completion, and discharge ;

[0030] 3) Preparation of hydroxyl-terminated ABA-type silicone-containing polyether polyol (component B): polydimethylsiloxane and methallyl polyether are added to a tetrahydrochloride with N2 in a molar ratio of 1:1.5 In a flask, heat to 45°C. Add 8 ppm of chloroplatinic acid with a syringe, observe the temperature change, control the temperature not to exceed 10...

Embodiment 3

[0033] 1) Trimethylolpropane dehydration: first add 1 mol trimethylolpropane into 200 ml ethyl acetate and stir to dissolve, remove water under reduced pressure at 80°C for 60 minutes, and then store under argon atmosphere;

[0034]2) Preparation of isocyanate-terminated carborane prepolymer (component A): under argon atmosphere, stir 0.32mol PAPI and 50ml ethyl acetate at 60°C, heat up to 70°C, add dehydrated Trimethylolpropane-butyl acetate and 1,7-dimethylolcarborane-ethyl acetate took 120 minutes; then heated up to 100°C for 4 hours to measure the isocyanate content, cooled to room temperature after completion, and discharged;

[0035] 3) Preparation of hydroxyl-terminated ABA-type silicone-containing polyether polyol (component B): polydimethylsiloxane and methallyl polyether are added to the tetrahydrochloride with N2 at a molar ratio of 1:2.5 In a flask, heat to 80°C. Add 15 ppm of chloroplatinic acid with a syringe, observe the temperature change, control the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com