Genetically engineered bacterium for co-production of 1, 3-propylene glycol and polyhydroxybutyrate as well as construction method and application thereof

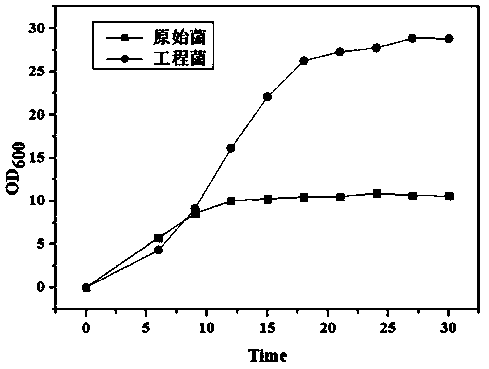

A technology of polyhydroxybutyrate and genetically engineered bacteria, which is applied in the field of genetic engineering, can solve the problems of reducing, inhibiting the growth of bacteria, increasing the cost of raw materials, and separating the cost of downstream products, so as to achieve relatively comprehensive economic benefits, increase biomass, and alleviate Effects of overflooding of acetic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: construct the recombinant Klebsiella pneumoniae that aldehyde / alcohol dehydrogenase gene (adhE), lactate dehydrogenase gene (ldhA) and fumarate reductase gene (frdA) delete

[0034] (1) Cloning of the upstream and downstream partial homologous sequences of the aldehyde / alcohol dehydrogenase gene (adhE)

[0035] Klebsiella pneumoniae ATCC 25955 genome was used as a template, primers were designed respectively, and the upstream homology arm and downstream homology arm of adhE gene were amplified by high-fidelity enzyme PCR.

[0036] Primers for PCR amplification of the upstream homology arm include adhE-F and adhE-F1:

[0037] adhE-F: ctatgacatgattacgaattcATGGCTGTTACTAATATCGCTGAACT;

[0038] adhE-F1: cattcgcgttatagcAGAGAAAATGATGGCGTTACGC.

[0039] The primers for PCR amplification of the homologous sequence of the downstream homology arm include adhE-R and adhE-R1:

[0040] adhE-R: tctctGCTATAACGCGAATGACAACCC;

[0041] adhE-R1: gccaagcttgcatgcctgcagTTTTT...

Embodiment 2

[0085] Example 2: Construction of recombinant plasmid pDK7-phbCBA

[0086] (1) Using the pBHR68 plasmid as a template to amplify the phbCBA gene (SEQ ID NO.4) derived from Cupriavidus necato, and design primers PHB-F and PHB-R required for PCR.

[0087] PHB-F: ggtacccggggatcctctagaGGGCAAGTACCTTGCCGAC,

[0088] PHB-R: tccgccaaaacagccaagcttCTTCTGAATCCATGACCAGCTGC.

[0089] The PCR system and amplification conditions are the same as step (1).

[0090] (2) Construction of expression plasmid pDK7-phbCBA

[0091] The pDK7 plasmid was digested with restriction endonucleases HindIII and XbaI, and the linearized pDK7 plasmid vector was recovered and purified by 1.0% agarose gel electrophoresis. The phbCBA gene fragment and the linearized pDK7 plasmid were ligated together using the ClonExpress MultiS OneStep Cloning Kit of Nanjing Nuoweizan Biotechnology Co., Ltd., and the ligated product was transformed into Escherichia coli DH5α (E.coli DH5α). 25 μg / mL) LB plates to screen positi...

Embodiment 3

[0092] Example 3: The recombinant plasmid pDK7-phbCBA was electrotransformed into recombinant Klebsiella pneumoniae Klebsiella pneumoniaeΔadhEΔldhAΔfrdA to construct Klebsiella pneumoniaeQ3-PHB

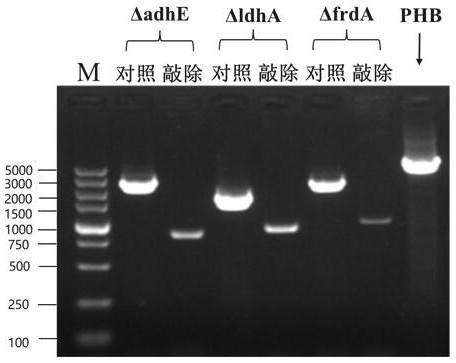

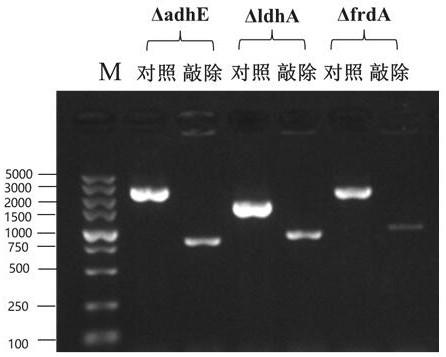

[0093] The recombinant plasmid pDK7-phbCBA was transformed into Klebsiella pneumoniaeΔadhEΔldhAΔfrdA using an electroporator, and the parameters of electroporation conditions were: voltage 2.5kv, resistance value 200Ω, pulse time 6.0msec. After electroporation, the electroporated Klebsiella pneumoniaeΔadhEΔldhAΔfrdA was washed out with pre-cooled liquid LB medium, cultured on a shaker at 37°C at 200rpm for 1-2 hours, and then spread on a medium containing 25μg / mL chloramphenicol. On the LB plate, colony PCR verification was performed with primers PHB-F and PHB-R, and the positive clone obtained was Klebsiella pneumoniaeQ3-PHB. The PCR verification of adhE gene, ldhA gene, frdA gene and phbCBA gene on Klebsiella pneumoniae Q3-PHB are all correct, the results are shown in figure 1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com