Preparation method of LED radiating fin with large radiating area

A technology of heat dissipation fins and heat dissipation area, applied in lighting and heating equipment, semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, etc., can solve the problems of low corrosion resistance, increased volume and weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

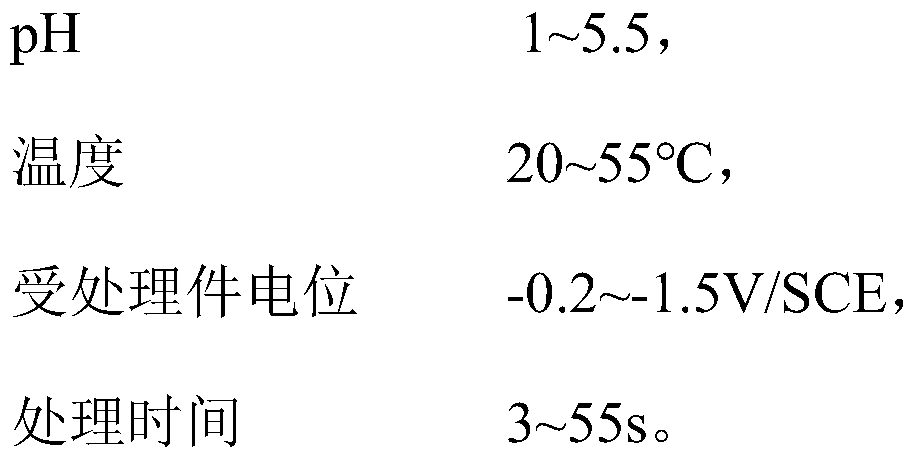

Method used

Image

Examples

preparation example 1

[0072] Preparation Example 1 Preparation of titanium nano polymer colloid:

[0073] 100g of pure titanium powder with metal content greater than 99.5%, pulverizer (low molecular weight epoxy resin E51) with 5% wt of titanium powder, pulverizer (oleic acid) with 5% wt of titanium powder, and 0.5% dispersant (byk170) was added to 100g colloidal carrier (xylene) together, stirred at 300rpm and mixed uniformly, took the mixture and added it to the pulverizer's tank for 3h grinding, after grinding, it was naturally cooled to room temperature, and then filtered to obtain the fineness Titanium nano-preliminary polymer below 50-75nm; then, 0.1%wt of anti-flocculant (naphthalene sulfonate formaldehyde condensate) and 0.2% wt of anti-flocculant of titanium powder mass are added to the titanium nano-prepolymer. Precipitating agent (stearic acid) and anti-precipitation agent (BYK410) with 2.5% titanium powder mass were colloidized by a horizontal ball mill for 2 hours, and finally a titanium...

preparation example 2

[0084] Preparation Example 2 Preparation of graphene colloid:

[0085] The composition of graphene colloid (in parts by mass) is: 5 parts of graphene, 0.1 part of wetting and dispersing agent, 10 parts of crosslinking agent, 0.3 part of anti-flocculant, 0.5 part of anti-settling agent, and 100 parts of colloidal carrier; Graphene 5 parts, wetting and dispersing agent (wetting and dispersing agent S596) 0.1 parts, crosslinking agent (2,5-dimethyl-2,5 di-tert-butylperoxyhexane) 10 parts, colloidal carrier (ring 100 parts of oxygen resin F51), stirred and mixed at 300 rpm, put into the tank of special equipment for graphene polymer preparation (disclosed in patent CN201821944605.6), grind for 2 hours to obtain the graphene colloid primary polymer; 0.3 part of anti-flocculant (Efka LP-9009) and 0.5 part of anti-settling agent (Deqian 202P) were added to the polymer, and the graphene colloid was obtained by grinding with a high-energy grinder for 1 hour.

preparation example 3

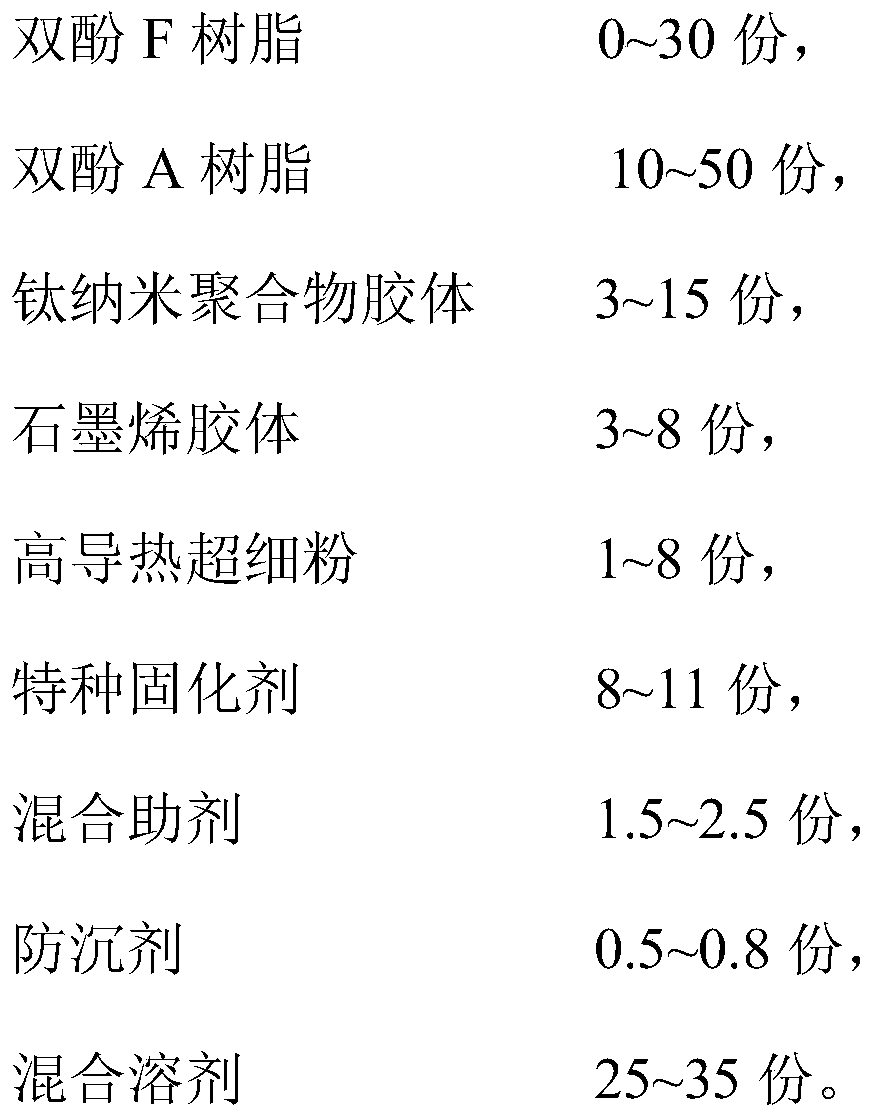

[0086] Preparation Example 3 Preparation of a rare metal heat-dissipating anti-corrosion coating for LED radiating fins: According to the following formula (in parts by mass):

[0087]

[0088] (1) Component A: add 33 parts of the above two resins, titanium nano polymer colloid, graphene colloid, silicon carbide, BYK301, BYK410 and mixed solvent into the paint tank, start stirring, mix evenly; sand to fine Degree 30μm, packed in bucket;

[0089] (2) Part B: Take T31 and add 12 parts of mixed solvent, and stir evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com