Preparation method of building template material

A technology of building formwork and glass fiber, which is applied in the field of preparation of building formwork materials, can solve the problems of little dependence on equipment, inconvenient construction and transportation, easy mildew and decay, etc., and achieves a simple and easy preparation method and anti-ultraviolet aging performance. and excellent flame retardancy, easy to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

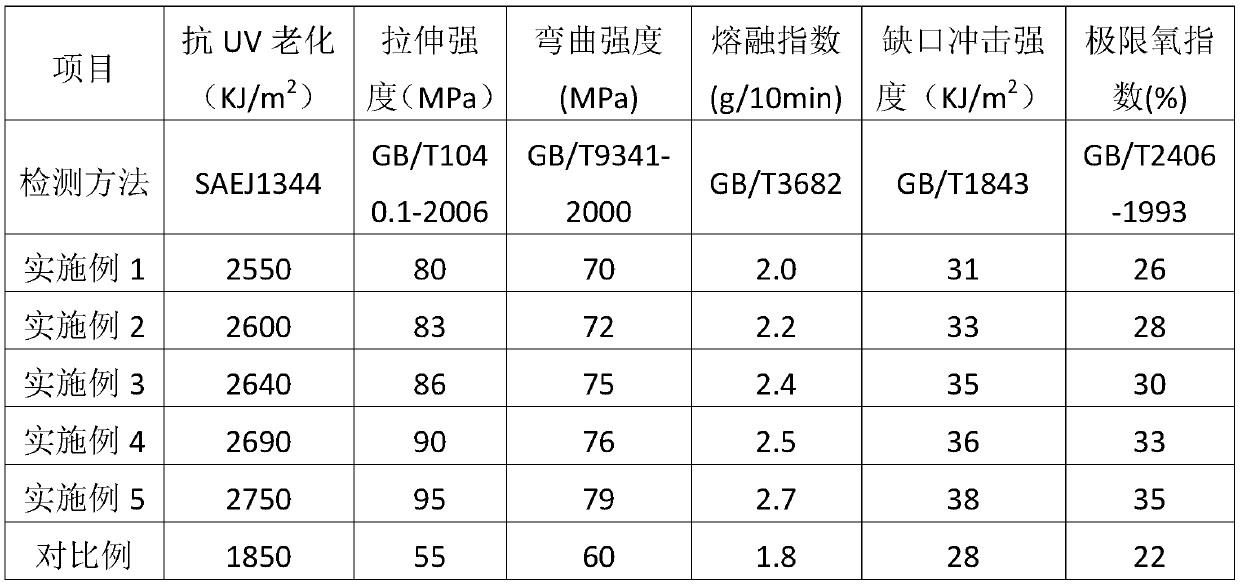

Examples

Embodiment 1

[0034] A building formwork material, made of the following components by weight: 10 parts of glass fibers coated with graphene oxide on the surface, 60 parts of fluorine-containing polysulfone condensation polymers, 30 parts of adamantyl sulfone-based addition polymers, three 1 part of phenylphosphine, 1 part of phenyl o-hydroxybenzoate, 1 part of calcium stearate.

[0035] The preparation method of the glass fiber whose surface is coated with graphene oxide comprises the steps of: dispersing 40 g of glass fiber in 100 g of ethanol, then adding 2 g of silane coupling agent KH550 therein, stirring at room temperature for 3 hours, and then adding graphene oxide 30g, continue to stir and react at 70°C for 5 hours, then filter, and then bake in a vacuum oven at 80°C for 10 hours.

[0036] The preparation method of the fluorine-containing polysulfone polycondensate comprises the following steps: 13.8 g of bis[4-(4-aminophenoxy)phenyl]sulfone, 1,4-bis(2',3'-ring Oxypropyl) perfluor...

Embodiment 2

[0042] A building formwork material, made of the following components by weight: 12 parts of glass fibers coated with graphene oxide on the surface, 63 parts of fluorine-containing polysulfone condensation polymers, 33 parts of adamantyl sulfone-based addition polymers, three 2 parts of ethylamine, 2 parts of 2-hydroxy-4-n-octyloxybenzophenone, 2 parts of N,N'-ethylene bisstearamide.

[0043] The preparation method of the glass fiber whose surface is coated with graphene oxide comprises the steps of: dispersing 45 g of glass fiber in 115 g of isopropanol, then adding 2.5 g of silane coupling agent KH550 thereto, stirring at room temperature for 3.5 hours, and then adding 35g of graphene oxide was stirred and reacted at 73°C for 6 hours, then filtered, and then baked in a vacuum oven at 83°C for 12 hours.

[0044] The preparation method of the fluorine-containing polysulfone polycondensate comprises the following steps: 13.8 g of bis[4-(4-aminophenoxy)phenyl]sulfone, 1,4-bis(2'...

Embodiment 3

[0050] A building template material, made of the following components by weight: 13 parts of glass fibers coated with graphene oxide on the surface, 65 parts of fluorine-containing polysulfone condensation polymers, 35 parts of adamantyl sulfone-based addition polymers, four 2 parts of butyl ammonium bromide, 2 parts of light stabilizer UV944, 1-3 parts of calcium stearate.

[0051] The preparation method of the glass fiber whose surface is coated with graphene oxide comprises the steps of: dispersing 50 g of glass fiber in 130 g of acetone, then adding 3.2 g of silane coupling agent KH550 thereto, stirring at room temperature for 4.2 hours, and then adding graphite oxide 42g of alkene was stirred and reacted at 77°C for 6.5 hours, then filtered, and then baked in a vacuum oven at 87°C for 13.5 hours.

[0052] The preparation method of the fluorine-containing polysulfone polycondensate comprises the following steps: 13.8 g of bis[4-(4-aminophenoxy)phenyl]sulfone, 1,4-bis(2',3'...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com