Biodegradable light-weight base soil and preparation method thereof

A biodegradable and light-weight technology, applied in fertilizer mixtures, organic fertilizers, fertilization devices, etc., can solve problems such as easy pollution, poor water retention effect, and inconformity with the concept of green environmental protection, and achieve easy control of the production process and excellent toughness and compatibility, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Porous composite material among the present invention is made up of biodegradable polymer, polycaprolactone, starch and cellulose, and its preparation method comprises the following steps:

[0044] 1) The plant straw is dried in the sun, crushed, hydrolyzed in 50% sulfuric acid solution for 30 minutes, then neutralized with NaOH solution, washed with distilled water until neutral, and dried to obtain plant cellulose.

[0045] 2) Surface-modified plant cellulose: soak the above-mentioned plant cellulose in 2mol / L NaOH solution and silane impregnating agent, soak for 2-3 hours at 50-70°C, filter and dry to obtain surface-modified fibers element; Wherein, the mass ratio of NaOH solution and silane impregnating agent is 1:(2-3).

[0046] 3) Cellulose / polycaprolactone mixing: Mix the above-mentioned surface-modified cellulose and polycaprolactone evenly, and react at a pressure of 5-8MPa and a temperature of 80-100°C for 1-2h to obtain crosslinking A mixture of cellulose / po...

Embodiment 1

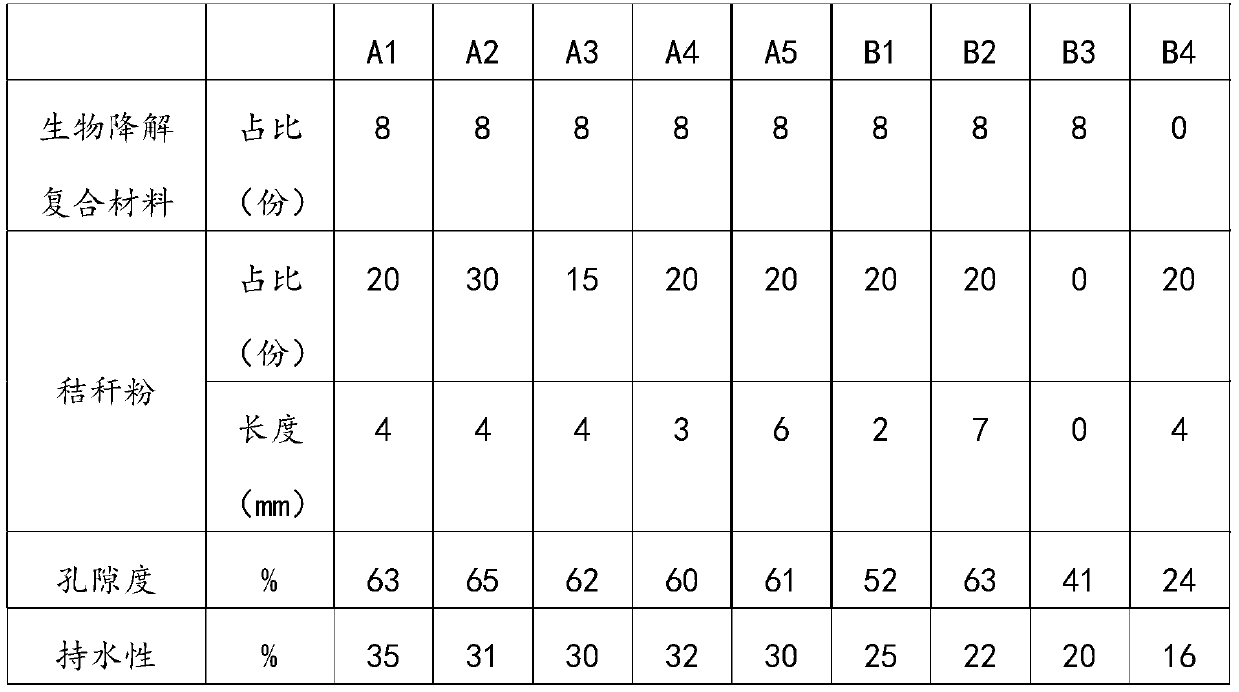

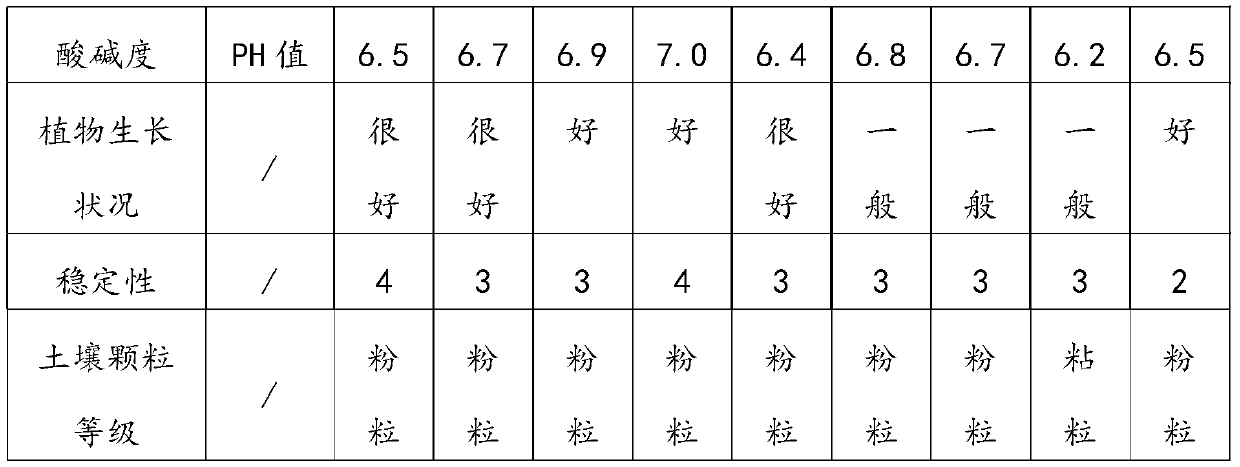

[0050] Embodiment 1: Preparation of biodegradable light base soil A1

[0051] (1) Dry and pulverize the straw to obtain a plant fiber powder with a length of 4 mm, then 30 parts of the plant fiber powder, 20 parts of loess, 15 parts of diatomite, 5 parts of zeolite, 15 parts of attapulgite, and vermiculite 8 parts and 7 parts of the base soil base material of the above-mentioned porous composite material were mixed and stirred evenly.

[0052] (2) Sterilize the soil base material mixed and configured in step (1), heat it at 160-170°C for 5 minutes, and use a molding device to mold the plastic soil into a film to obtain a plastic soil block A1. Then the porosity, water holding capacity, plant growth status, stability of the base soil, pH value and soil particle composition of the plastic base soil block were tested according to the above test method, and the measured test results are shown in Table 2.

Embodiment 2

[0053] Embodiment 2: the preparation of biodegradable light base soil A2

[0054] The preparation method of A2 is the same as that of A1 in Example 1, and the specific steps are with reference to Example 1. It is worth noting that the base soil base material ratio in A2 is 40 parts of plant fiber powder, 15 parts of loess, 10 parts of diatomaceous earth, 5 parts of zeolite, 15 parts of attapulgite, 8 parts of vermiculite, and 7 parts of porous composite material. The test results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com