Process for separating and removing citrinin in nuclease liquid by utilizing chromatographic technology

A technology of nuclease liquid and chromatographic technology, which is applied in the field of separation and removal of citrinin in nuclease liquid by chromatographic technology to achieve the effects of reducing energy consumption, ensuring purity and quality, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: Obtaining of nuclease P1 solution.

[0047] Inoculate Penicillium citrinum into 100mL seed culture medium and incubate at 30°C for 24h; then inoculate the seed culture liquid into the fermentation medium according to the inoculation amount of 10vt%, the initial pH is 6.50, the fermentation temperature is 30°C, and the culture time is 50h. The obtained fermented liquid is firstly centrifuged to remove impurities such as proteins and polysaccharides, and the supernatant is used for later use. Wherein, the mass percent of each component in the described seed culture medium is as follows: glucose 5%, peptone 0.5%, KH 2 PO 4 0.05%, K 2 HPO 2 ·3H 2 O 0.05%, MgSO 4 0.04%, CaCl 2 0.04%, pH 6.50; the mass percentage of each component in the fermentation medium is seed medium+ZnSO 4 ·7H 2 O 0.04%.

[0048] Repeat the experiment four times according to the above method, and obtain four batches of clear liquid respectively; In the first batch of clear liquid,...

Embodiment 2

[0049] Example 2: Citrinin removal rate measured by static shake flask.

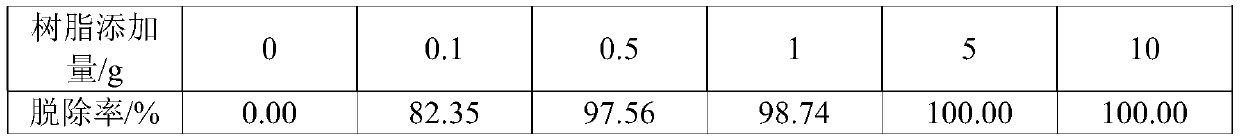

[0050] In six 250mL conical flasks, add 0,0.1,0.5,1,5,10g chlorine type 717 strong anion exchange resin resins successively, pour into the higher nuclease P1 liquid of 100mL citrinin content in order (to the embodiment Add the citrinin standard to the uncentrifuged fermented liquid prepared in 1, so that the final content of citrinin is 3.752ppm), seal it, and place it in a shaker at 150r / min and a temperature of 25°C for 8 hours. The supernatant was taken, and the concentration of citrinin was detected by HPLC. The color of the nuclease P1 solution with different resin additions changes differently, such as figure 2 (from left to right are 0, 0.1, 0.5, 1, 5, 10g of resin added), the greater the amount of resin added, the lighter the color of the nuclease P1 solution, indicating that the nuclease was treated with Cl type 717 resin P1 solution has a certain decolorization effect. Table 1 shows the rem...

Embodiment 3

[0056] Example 3: Chromatographic separation of nuclease P1 solution.

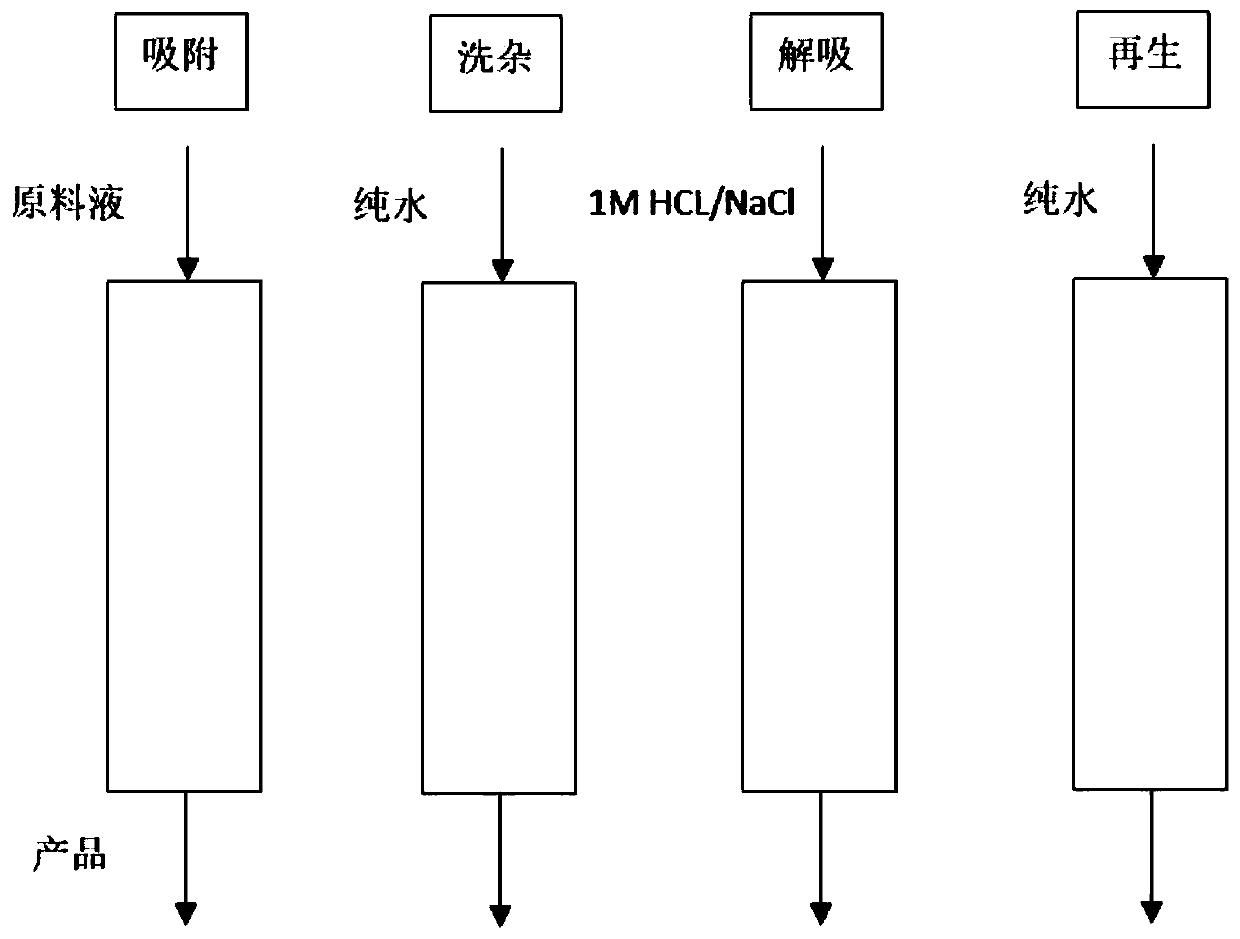

[0057] A separation system consisting of a resin column packed with adsorbent, a peristaltic pump and an automatic fraction collector is used. The resin column is filled with 0.6L resin (Cl type 717), the diameter of the resin column is 5cm, and the height is 70cm. Put the first batch of nuclease solution P1 pretreated in Example 1 on the column, the concentration of the column: nuclease P1 enzyme activity 2000U / mL, citrinin 0.034ppm, use 1M HCl / NaCl as desorbent, saturated adsorption capacity is 7.504*10 -2 g / g wet resin; by switching the mobile phase, the whole system is divided into four steps of adsorption, impurity washing, desorption and regeneration, switching in sequence, and the advanced nuclease P1 solution is switched to pure water for washing after the resin column is saturated with citrinin. Miscellaneous, collect the product liquid at the outlet of the adsorption section, then switch to 1M ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com