Pre-treatment liquid and ink set

A technology of pretreatment liquid and water-based inkjet ink, applied in the direction of ink, duplication/marking method, application, etc., can solve the problems of unsuitable for actual use, long-term printing, poor operability, etc., and achieve excellent storage stability, durability Excellent blocking and drying properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~67

[0326] [Examples 1-67, Comparative Examples 1-14]

[0327] 1. Manufacture of pretreatment solution

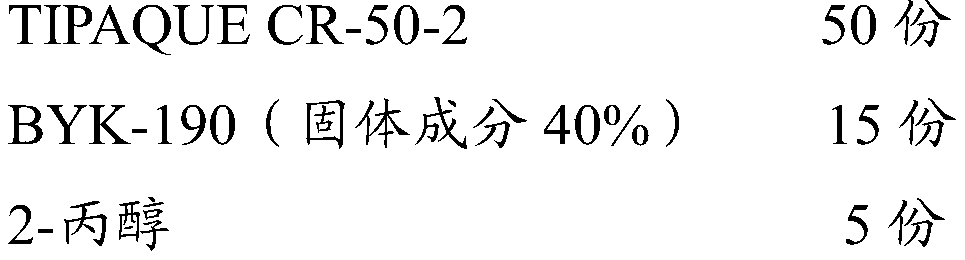

[0328]

[0329] The following materials were put into a mixing container equipped with a mixer, and mixed and stirred (premixed) for 1 hour. Thereafter, main dispersion was performed using a 0.6-L Dyno Mill filled with 1,800 g of zirconia beads with a diameter of 1 mm to obtain a titanium oxide dispersion (50% pigment concentration).

[0330]

[0331]

[0332] In the above production examples, TIPAQUE CR-50-2 is titanium oxide manufactured by Ishihara Sangyo Co., Ltd., and BYK-190 is an aqueous solution of styrene-maleic acid resin manufactured by BYK Chemical Corporation.

manufacture example

[0334] After putting the following materials into the mixing container equipped with the stirrer, mixing and stirring for 1 hour, it heated to 90 degreeC, and mixed for 1 hour further. Thereafter, it was left to cool to room temperature, and adjusted with ion-exchanged water so that the solid content became 25%, thereby obtaining a PVA103 varnish.

[0335] Kuraray Poval PVA103 25 parts

[0336] 75 parts of ion-exchanged water

[0337] In the above production example, Kuraray Poval PVA103 is a polyvinyl alcohol resin (water-soluble resin, melting point: 200° C.) manufactured by Kuraray Corporation.

[0338]

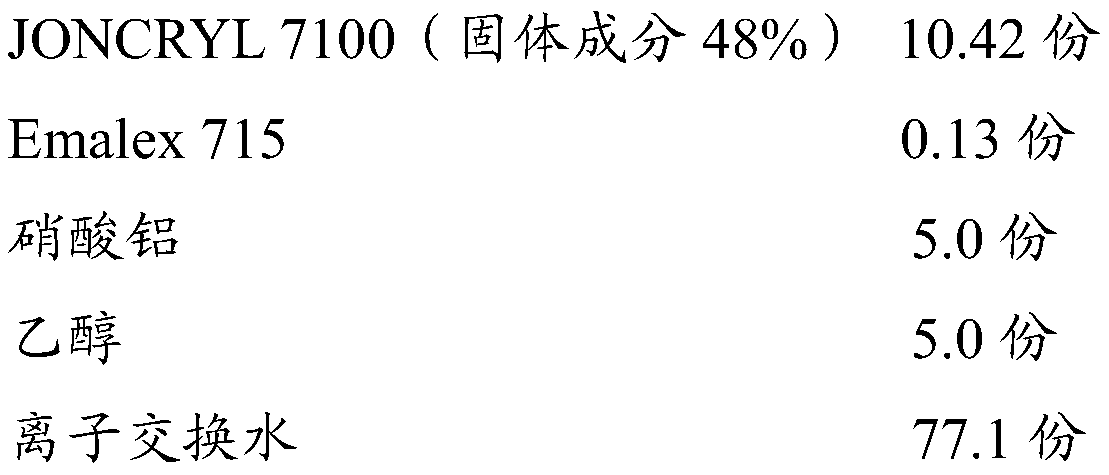

[0339] The following materials were put into the mixing container equipped with the stirrer, and after mixing at room temperature (25 degreeC) for 1 hour, it heated to 50 degreeC, and further mixed for 1 hour. Next, the mixture was cooled to room temperature, and then filtered through a membrane filter with a pore size of 1 μm to obtain a pretreatment liquid 1 .

[03...

Embodiment 68~160、 comparative example 15~28

[0415] 3. Production example of membrane base material with pretreatment solution

[0416] After coating the pretreatment solution prepared above with a wet film thickness of 4.0 ± 0.2 μm on the following film substrates using the K control coater K202 manufactured by Matsuo Sangyo Co., Ltd., wire bar No. 0, the pretreatment solution coated with the above The film base material was put into an air oven at 70° C. and dried for 3 minutes to prepare a film base material to which the pretreatment liquid was applied.

[0417]

[0418] OPP: Biaxially oriented polypropylene film "OPU-1" (thickness 20 μm) manufactured by Mitsui Chemicals East Cello Co., Ltd.

[0419] PET: Polyethylene terephthalate film "LUMIRROR T60" (thickness: 25 μm) manufactured by Toray Corporation

[0420]

[0421] Install an inkjet head KJ4B-QA (manufactured by Kyocera Corporation, design resolution 600dpi) on the upper part of the conveyor belt capable of conveying the substrate, and place the water-based...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com