Method for efficient catalytic synthesis of epoxy bisphenol fluorene

A technology for epoxy bisphenol fluorene and bisphenol fluorene, which is applied in the field of efficient catalytic synthesis of epoxy bisphenol fluorene, can solve the problems of epoxy bisphenol fluorene resin yield report, increase in organic waste liquid, increase in production cost, etc. The effect of shortening reaction time, good chromaticity and improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

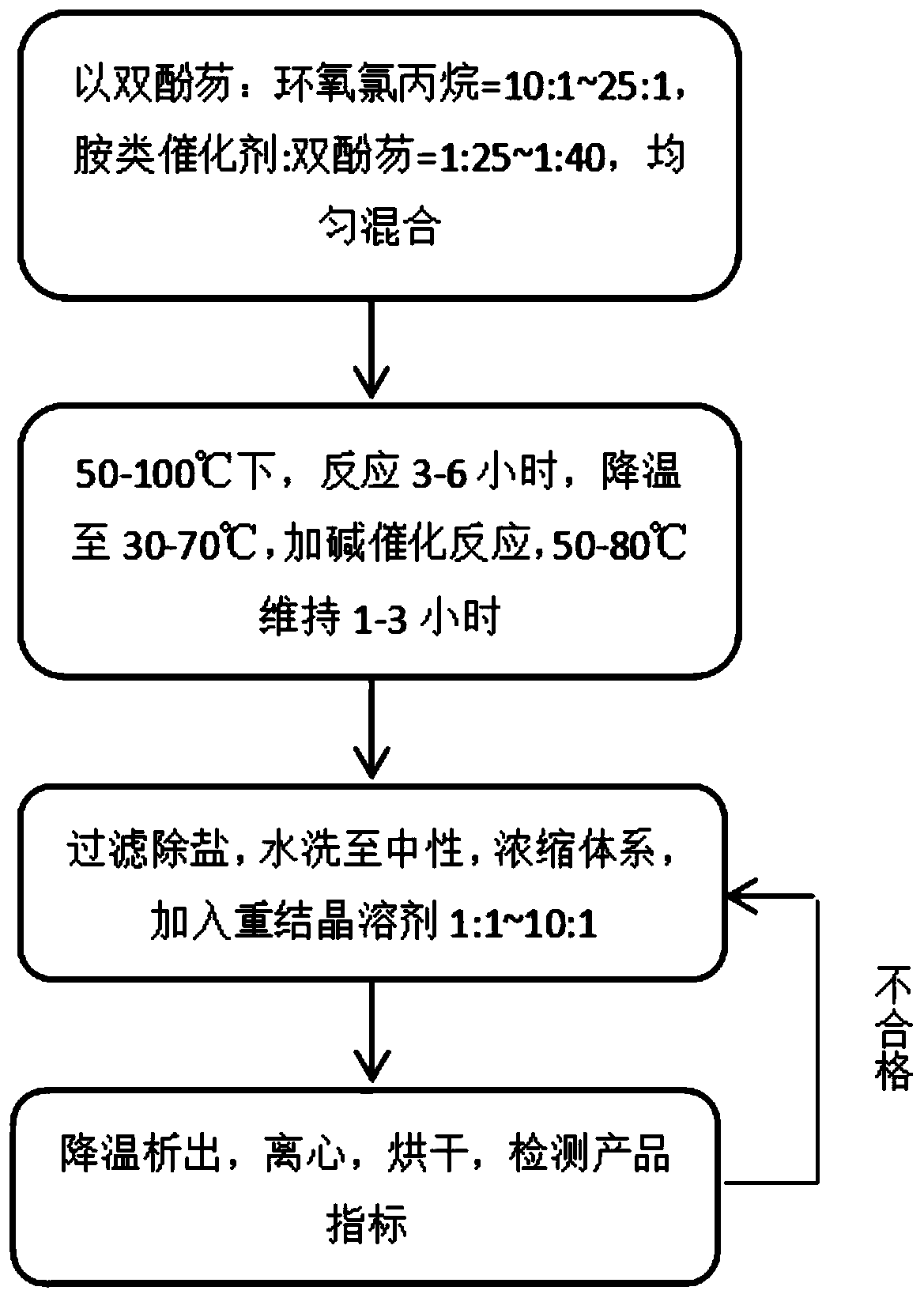

Method used

Image

Examples

specific Embodiment approach

[0024] Below in conjunction with the examples, the specific implementation of the present invention will be further described in detail. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0025] The reactants used in the following comparative examples and examples and the reaction products obtained were analyzed and detected by high performance liquid chromatography analyzer.

Embodiment 1

[0030] Adopt the method of the present invention, prepare according to the following steps:

[0031] Add 180g of bisphenol fluorene, 6g of tetrabutylammonium bromide and 620.3g of epichlorohydrin into a 1000ml three-necked flask equipped with mechanical stirring, a thermometer and a reflux condenser, and add the three-necked flask to a water bath at 55°C. The system is completely dissolved and clarified. Control the temperature in the kettle to 60-90°C, gradually increase the temperature, react for 4 hours, lower the temperature to control the temperature of the kettle to 65-70°C, add 45g of sodium hydroxide, and maintain the temperature of the kettle at 65-70°C after adding alkali. React for 1 hour, after cooling down, wash with water, desolventize the reaction solution after washing with water, beat with 195g acetonitrile, cool down, filter with suction to obtain a wet product, dry to obtain a white solid, the actual yield is 90.15% , the purity of the product characterized ...

Embodiment 2

[0033] Adopt the method of the present invention, prepare according to the following steps:

[0034] Add 180g of bisphenol fluorene, 6g of tetrabutylammonium bromide and 620.3g of epichlorohydrin into a 1000ml three-necked flask equipped with mechanical stirring, a thermometer and a reflux condenser, and add the three-necked flask to a water bath at 55°C. The system is completely dissolved and clarified. Control the temperature in the kettle to 60-90°C, gradually increase the temperature, react for 4 hours, lower the temperature to control the temperature of the kettle to 65-70°C, add 50g of sodium hydroxide, and after the addition of alkali, maintain the temperature of the kettle at 65-70°C. React for 1 hour, after cooling down, wash with water, desolventize the reaction solution after washing, beat with 195g acetonitrile, cool down, filter with suction to obtain a wet product, dry to obtain a white solid, the actual yield is 91.03% , the purity of the product characterized b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com