Organic-inorganic hybrid anti-fog coating and preparation method thereof

An anti-fog coating, inorganic technology, applied in coatings, anti-fouling/underwater coatings, conductive coatings, etc., can solve the problems of destroying the anti-fog effect of functionalized coatings, reducing surface free energy, etc., to improve self-cleaning ability, lowering resistance value, and the effect of uniform coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

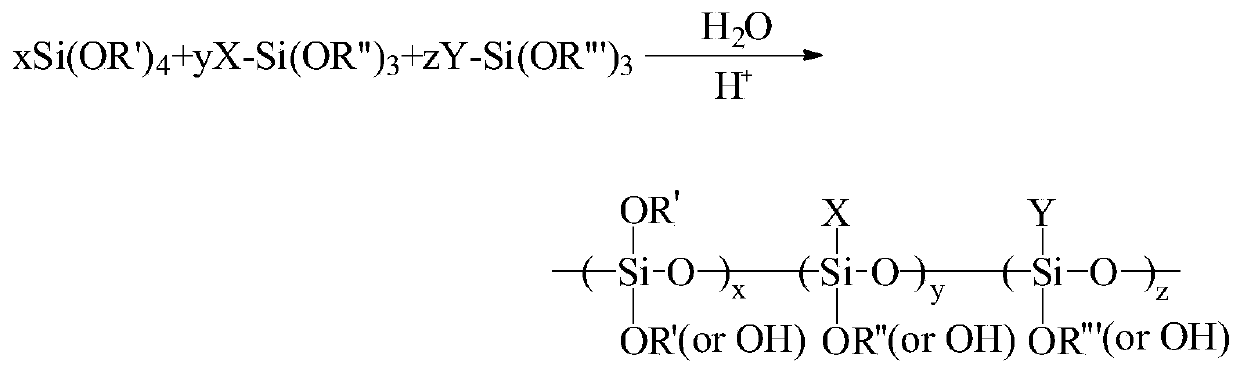

Method used

Image

Examples

Embodiment 1

[0067] Under the protection of nitrogen, respectively add 30g of acrylic acid, 10g of hydroxyethyl acrylate, 100g of acrylamide, and 5g of vinyltriethoxysilane into a reaction kettle of 200g of isopropanol, stir evenly, and then add 1g of photoinitiator 1- Hydroxycyclohexyl phenyl ketone and 10g of chain transfer agent n-dodecyl mercaptan were stirred until dissolved, and then the system was placed under ultraviolet light for 20-30 minutes to react, and then added dropwise to it and dispersed in isopropanol Hydrophobic monomer methyl methacrylate and ethyl acrylate mixed solution, the dropping rate is controlled at 0.5-1 drop / s, after the addition is completed, the constant temperature reaction is continued for 1-2 hours, after the reaction, the hydrophilic acrylate resin.

[0068] Disperse 10g of tetraethyl orthosilicate (TEOS) in 43g of absolute ethanol, add 3g of glacial acetic acid and stir to mix evenly, add 6g of ionized water dropwise while stirring, hydrolyze at 40°C f...

Embodiment 2

[0071] Under nitrogen protection, add 100g of acrylic acid, 10g of methacrylic acid, 15g of N-hydroxyethylacrylamide, and 5g of γ-methacryloxypropyltrimethoxysilane into a reaction kettle of 200g of absolute ethanol, and stir evenly. Then add 1g photoinitiator 2-hydroxyl-2-methyl-phenylacetone and 10g chain transfer agent sodium methacrylate sulfonate and stir until dissolved, then place the system under ultraviolet light to react for 20-30min, Then dropwise add a mixed solution of hydrophobic monomer methyl methacrylate and ethyl acrylate dispersed in absolute ethanol, the dropping rate is controlled at 0.5-1 drop / s, and after the dropping is completed, continue the constant temperature reaction for 1-2 hours. After the reaction, the hydrophilic acrylate resin is obtained.

[0072] Disperse 15g of tetraethyl orthosilicate (TEOS) in 47g of isopropanol, add 1g of hydrochloric acid and stir to make it evenly mixed, add 4g of ionized water dropwise under stirring, hydrolyze at 40...

Embodiment 3

[0075] Under nitrogen protection, add 80g acrylic acid, 10g ethylacrylic acid, 35g N,N dimethylacrylamide, 15g N-hydroxyethylacrylamide, 5gγ-methacryloxypropyltrimethoxysilane to 200g In the reaction kettle of water ethanol, stir evenly, then add 1g photoinitiator diphenyl-(2,4,6-trimethylbenzoyl)phosphine and 10g chain transfer agent α-methylstyrene linear Stir the dimer until it dissolves, and then place the system under ultraviolet light to react for 20-30 minutes, and then dropwise add a mixed solution of hydrophobic monomer methyl methacrylate and ethyl acrylate dispersed in absolute ethanol, The dropping rate is controlled at 0.5-1 drop / s. After the dropping is completed, the constant temperature reaction is continued for 1-2 hours. After the reaction is completed, the hydrophilic acrylate resin is obtained.

[0076] Disperse 15g of tetraethyl orthosilicate (TEOS) in 47g of isopropanol, add 1g of hydrochloric acid and stir to make it evenly mixed, add 4g of ionized water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com