Preparation method for tungsten carbide reinforced nickel-based composite coating

A composite coating and tungsten carbide technology, which is applied in the coating, metal material coating process, etc., can solve the problems of binder pollution on the substrate surface, easy generation of pores in the cladding layer, and increased stress of the cladding layer, etc., to achieve Easy to automate control, avoid pollution and porosity, and reduce the effect of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing a tungsten carbide reinforced nickel-based composite coating, comprising the following steps:

[0031] Mix cobalt-coated tungsten carbide powder with nickel-based self-fluxing alloy powder to obtain composite powder;

[0032] Using a synchronous powder feeding method, the composite powder is sent to the surface of the substrate, and laser cladding is carried out in a protective atmosphere to form a tungsten carbide reinforced nickel-based composite coating on the surface of the substrate;

[0033] The content of cobalt-coated tungsten carbide powder in the composite powder is 10-20wt%;

[0034] During the laser cladding process, the size of the rectangular spot used is (10-15) mm×(1-2) mm, the laser power is 2400-2600 W, and the scanning speed is 5-8 mm / s.

[0035] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in the a...

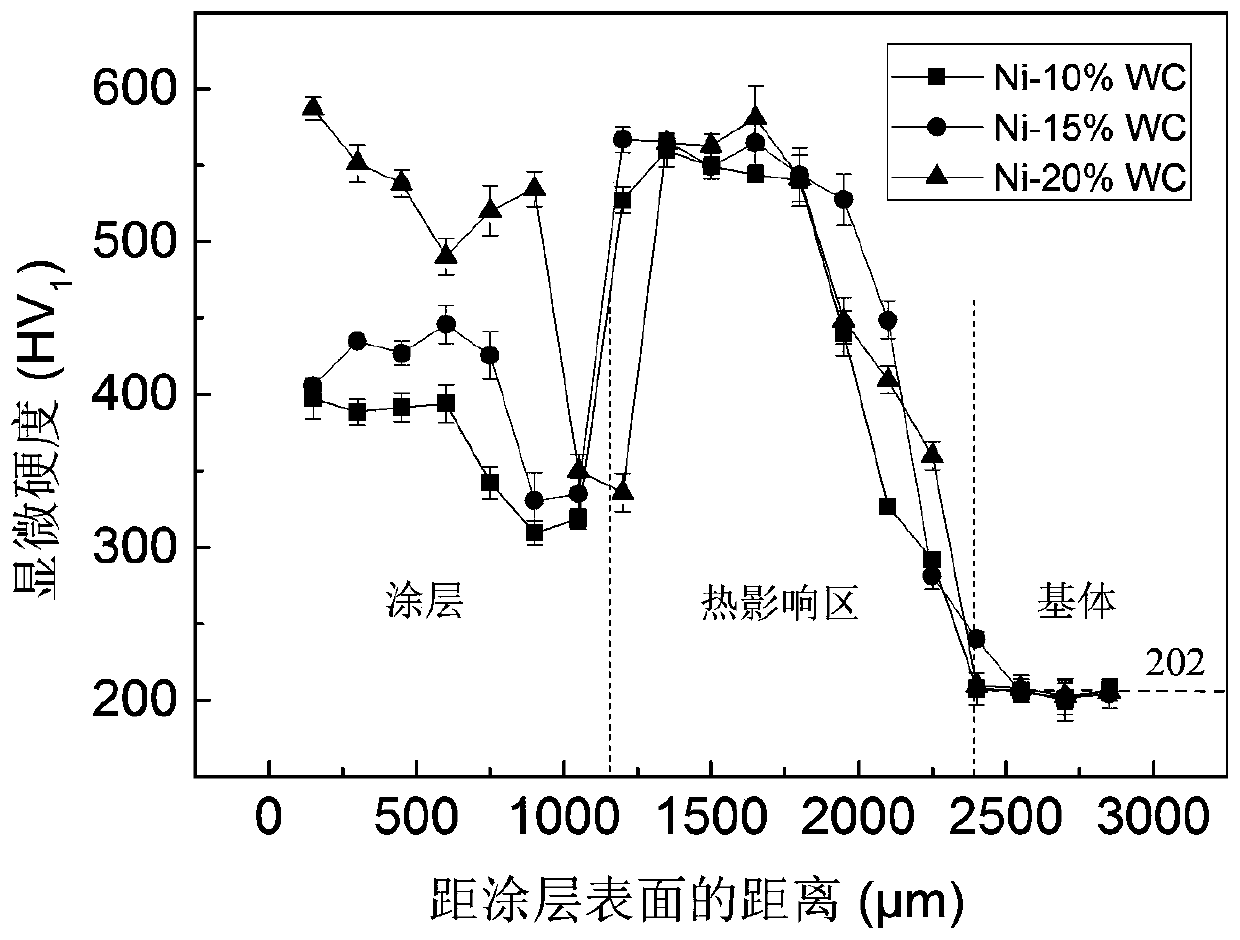

Embodiment 1

[0053] 2Cr13 martensitic stainless steel is ground and degreased as a base material, its size is 10cm×10cm×1cm, and 10% by mass of cobalt-coated tungsten carbide powder is mixed with the remainder of Inconel625 nickel-based self-fluxing alloy powder Evenly, the composite powder is obtained, and the composite powder is dried in a constant temperature drying oven at 200°C for 2 hours;

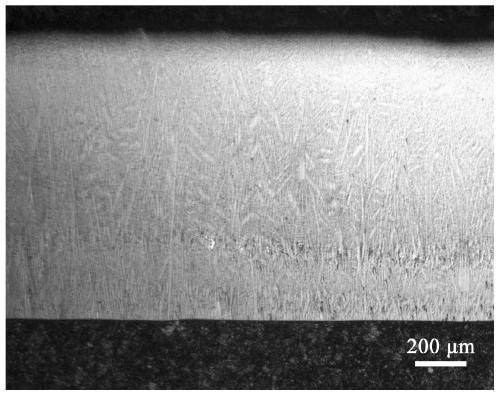

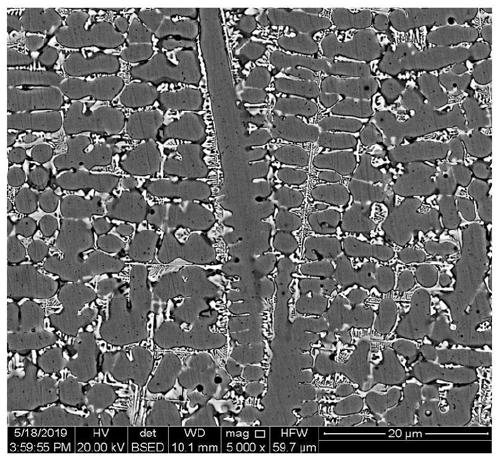

[0054] The laser head of the third-generation fiber laser is perpendicular to the surface of the substrate to be clad, and the coaxial powder feeding device is used to feed the composite powder into the surface of the substrate, and the single-channel-multilayer stacking method is used in an argon protective atmosphere. Laser cladding, 4 layers of cladding for each layer. After each layer of cladding is completed, use a wire brush to clean off the oxides on the surface, and continue cladding the lower layer until a laser cladding layer with a thickness of 1.1-1.2mm is obtained, that is, tungsten c...

Embodiment 2

[0056] 2Cr13 martensitic stainless steel is ground and degreased as the base material, its size is 10cn×10cm×1cm, the mass percentage is 15% of cobalt-coated tungsten carbide powder and the balance of Inconel625 nickel-based self-fluxing alloy powder is mixed Evenly, the composite powder is obtained, and the composite powder is dried in a constant temperature drying oven at 200°C for 2 hours;

[0057] The laser head of the third-generation fiber laser is perpendicular to the surface of the substrate to be clad, and the coaxial powder feeding device is used to feed the composite powder into the surface of the substrate, and the single-channel-multilayer stacking method is used in an argon protective atmosphere. Laser cladding, 4 layers of cladding for each layer. After each layer of cladding is completed, use a wire brush to clean off the oxides on the surface, and continue cladding the lower layer until a laser cladding layer with a thickness of 1.1-1.2mm is obtained, that is, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com