Preparation method of shell-core structure composite material of nano carbon material coated metal compound

A technology of nano-carbon materials and metal compounds, applied in the field of material processing, can solve the problems of low performance of hybrid composite materials and achieve the effect of firm combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

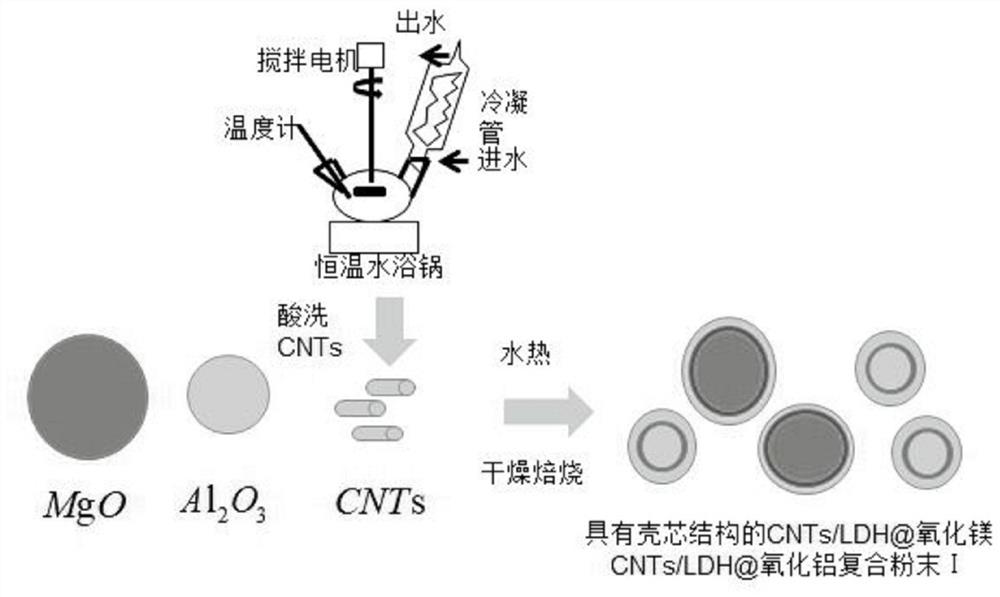

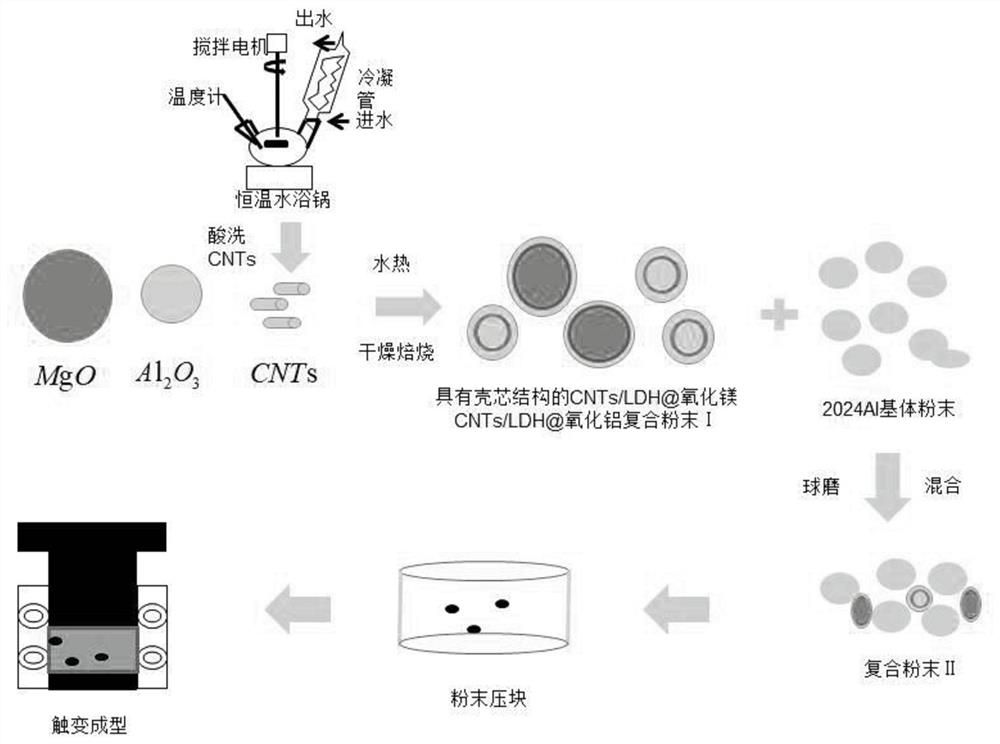

[0033] Such as figure 1 Shown: the preparation has a certain amount of nano-scale MgO, Al2O3, CNTs mixed solution. Weigh 0.162g of MgO, 0.102g of Al2O3, 0.049g of acidified CNTs, and 0.15g of urea. Add deionized water and mix to prepare 50ml of mixed solution, sonicate for 10min, and transfer to a 100ml polytetrafluoroethylene-lined container.

[0034] The mixture was placed in a hydrothermal reaction kettle, heated at 120°C for 12 hours, cooled with the furnace, and then taken out. After centrifugation and washing, 6000r / min, centrifugation for 5min, pour off the supernatant, keep the black solid in the lower layer, wash 3 times, transfer to a petri dish and dry at 60°C for 4h, you can get CNTs / LDH coated MgO, CNTs / LDH Coated Al2O3 composite material.

Embodiment 2

[0036] Prepare a mixed solution with a certain amount of micron MgO, aluminum nitrate and CNTs. Weigh 0.162g of MgO, 0.750g of aluminum nitrate nonahydrate, 0.049g of acidified CNTs, 0.2g of sodium carbonate, and 0.2g of sodium hydroxide. Add deionized water and mix to prepare 50ml of mixed solution, sonicate for 10min, and transfer to a 100ml polytetrafluoroethylene-lined container.

[0037] Place the mixed solution in a hydrothermal reaction kettle, heat it at 140°C for 16 hours, take it out after cooling in the furnace, and wash it by centrifugation at 8000r / min for 5 minutes, pour off the supernatant, keep the black solid in the lower layer, wash 3 times, and transfer to The CNTs / LDH-coated MgO composite was obtained by drying in a petri dish at 80°C for 4 hours.

Embodiment 3

[0039] Prepare a mixed solution of AlN, GO and magnesium nitrate with a certain amount of nanometer. Weigh AlN, 0.592g of magnesium nitrate, 0.05g of GO, 0.25g of ammonia water, and 0.2g of sodium chloride. Add deionized water and mix to prepare 50ml of mixed solution, sonicate for 10min, and transfer to a 100ml polytetrafluoroethylene-lined container.

[0040] The mixed solution was placed in a hydrothermal reaction kettle, heated at 130°C for 16 hours, and then taken out after cooling with the furnace to realize the in-situ growth of CNTs / LDH.

[0041] After centrifugation and washing at 8000r / min, centrifuge for 5min, pour off the supernatant, keep the black solid in the lower layer, wash 3 times, transfer to a petri dish and dry at 60°C for 4h, then the CNTs / LDH coated AlN composite material can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com