Polymer solid electrolyte and preparation method thereof

A solid electrolyte and polymer technology, used in composite electrolytes, electrolyte battery manufacturing, non-aqueous electrolyte batteries, etc., can solve the problems of inability to rapidly transmit lithium ions, defective performance, and poor ion conductivity, and improve thermal stability. and electrochemical stability, good electrochemical stability and thermal stability, the effect of reducing energy efficiency and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0061] According to some embodiments provided by the present invention, the preparation method of the polymer solid electrolyte includes:

[0062] Stirring and mixing the polymer matrix, lithium salt and inorganic filler in an organic solvent to obtain a slurry;

[0063] The above slurry was cast into a mold and dried in vacuum to obtain a polymer solid electrolyte.

[0064] According to some embodiments provided by the present invention, the polymer matrix is PVDF or a mixture of PVDF and PEO.

[0065] According to some embodiments provided by the present invention, when the polymer matrix is a mixture of PVDF and PEO, the mass ratio of PEO to PVDF is 1:3-25, for example: 1:5, 1:6, 1:7 , 1:8, 1:9, 1:10, 1:11, 1:12, 1:13, 1:14, 1:15, 1:16, 1:17, 1:18, 1:19, 1 :20, 1:21, 1:22, 1:23, 1:24, 1:25, etc.

[0066] In some embodiments, when the polymer matrix is a mixture of PVDF and PEO, the mass ratio of PEO to PVDF is 1:3-15.

[0067] According to some embodiments provide...

Embodiment 1

[0098] Preparation of 3(5PVDF-PEO)-(LTTBA-3LiTFSI)-0.1ZnO polymer solid electrolyte, in which the ratio of matrix (PVDF-PEO) to lithium salt (LTTBA-3LiTFSI) is 3:1, ZnO and polymer solid electrolyte The ratio of the total mass (matrix + lithium salt + ZnO) is 0.1:1, the mass ratio of PVDF to PEO is 5:1, and the mass ratio of LTTBA to LiTFSI is 1:3.

[0099] Weigh 1g LTTBA, 3g LiTFSI, 10g PVDF, 2g PEO and 1.78g ZnO in 150mL DMAC solvent, stir at 30°C for 6h to obtain a polymeric solid electrolyte slurry, and then cast the slurry in a polytetrafluoroethylene mold for self-leveling , transferred to a vacuum drying oven, and dried in vacuum at 30° C. for 24 hours to obtain a polymer solid electrolyte of 3(5PVDF-PEO)-(LTTBA-3LiTFSI)-0.1ZnO.

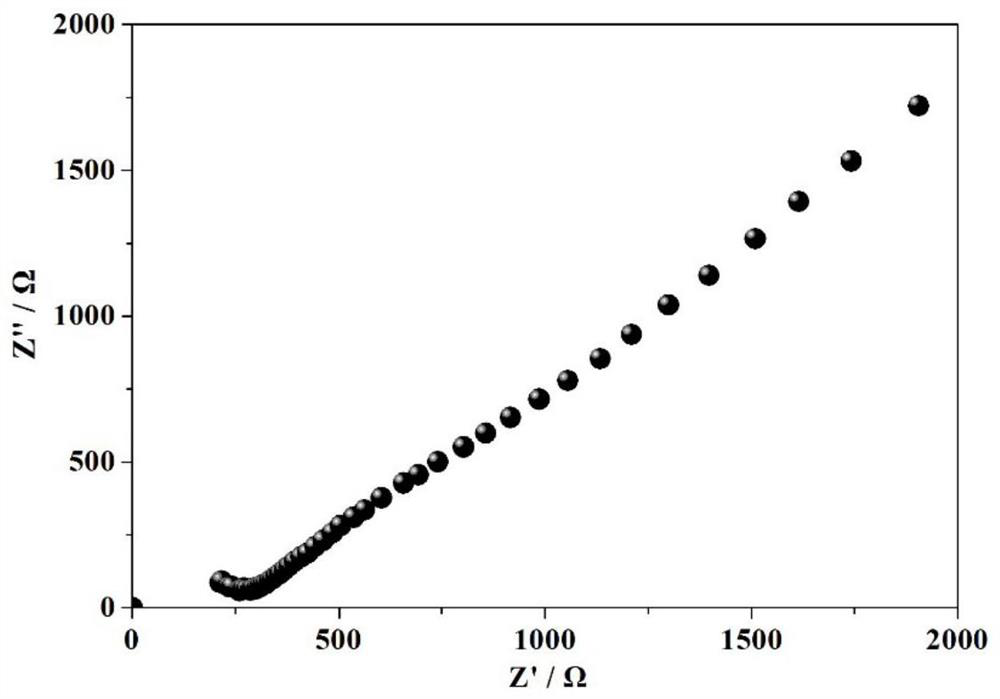

[0100] Cut the obtained polymer solid electrolyte into discs with a diameter of 15 mm and a thickness of about 170 μm, and conduct an AC impedance test on it, and the results are as follows figure 1 As shown, its impedance value is about 260Ω...

Embodiment 2

[0102] 5(9PVDF-PEO)-(LTTBA-LiClO 4 )-0.15LAGP polymer solid electrolyte, in which the matrix (PVDF-PEO) and lithium salt (LTTBA-LiClO 4 ) ratio is 5:1, the ratio of LAGP to the total mass of polymer solid electrolyte (matrix + lithium salt + ZnO) is 0.1:1, the mass ratio of PVDF to PEO is 9:1, LTTBA to LiClO 4 The mass ratio is 1:1.

[0103] Weigh 1g LTTBA, 1gLiClO 4 , 9g PVDF, 1gPEO and 2.12gLAGP in 170mL acetonitrile solvent, stirred at 30°C for 12h to obtain a polymerized solid electrolyte slurry, then cast the slurry in a polytetrafluoroethylene mold for self-leveling, transfer it to a drying oven, and Purged and dried with nitrogen at 30°C for 18 h to obtain 5(9PVDF-PEO)-(LTTBA-LiClO 4 )-0.15LAGP polymer solid electrolyte.

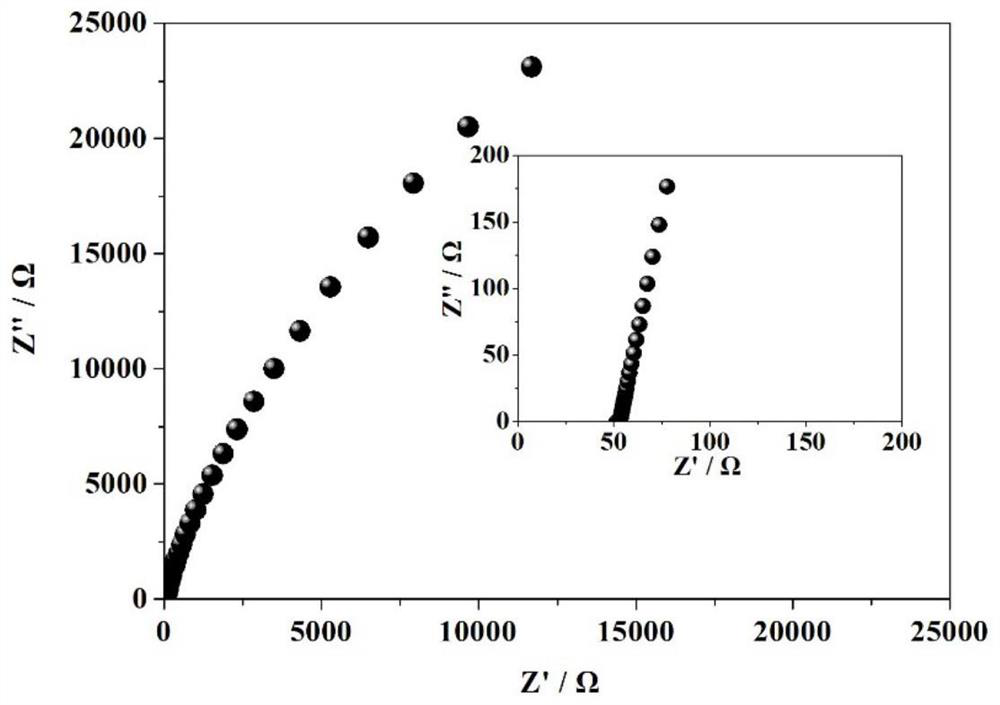

[0104] Cut the obtained polymer solid electrolyte into discs with a diameter of 15 mm and a thickness of about 136 μm, and conduct an AC impedance test on it, and the results are as follows figure 2 As shown, it can be seen from the calculation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impedance value | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Impedance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com