Josephson traveling wave amplifier and preparation method thereof

An amplifier and microwave technology, applied in the field of Josephson traveling wave amplifier and its preparation, can solve the problems of complex structure and difficult processing in the laboratory, and achieve the effects of simplifying the preparation steps, avoiding excessive device size and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 of the present application provides a Josephson traveling wave amplifier, which can meet the needs of measuring weak signals close to the quantum limit, can be applied in the measurement of qubits, simplifies the preparation process, greatly reduces the difficulty of device preparation, and can ensure The performance of the device meets the requirements.

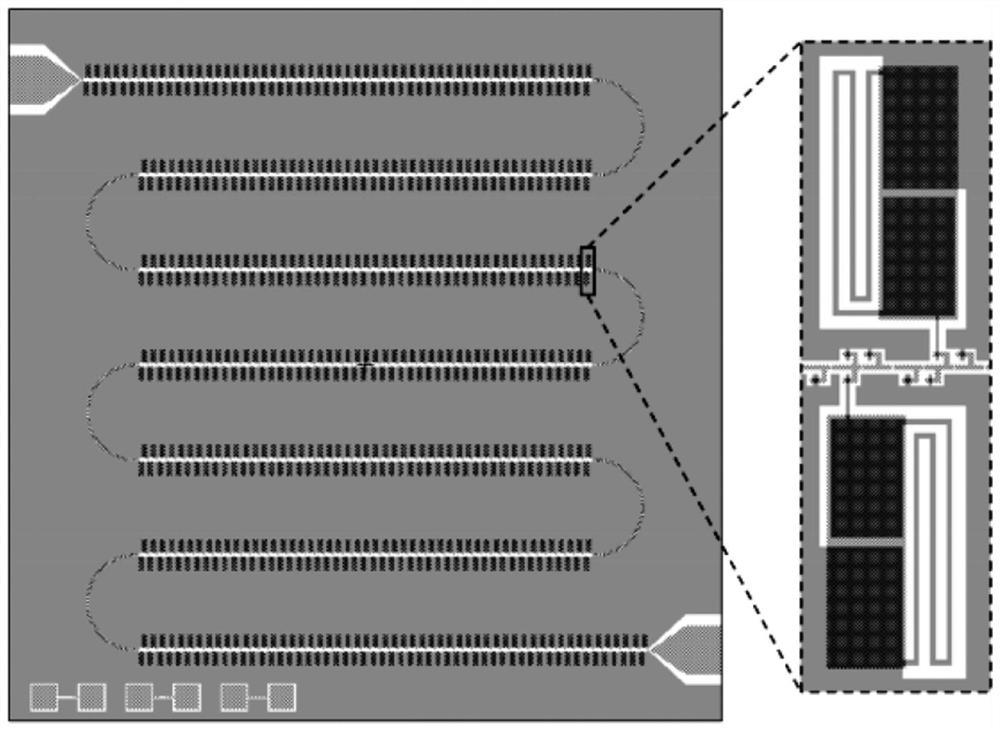

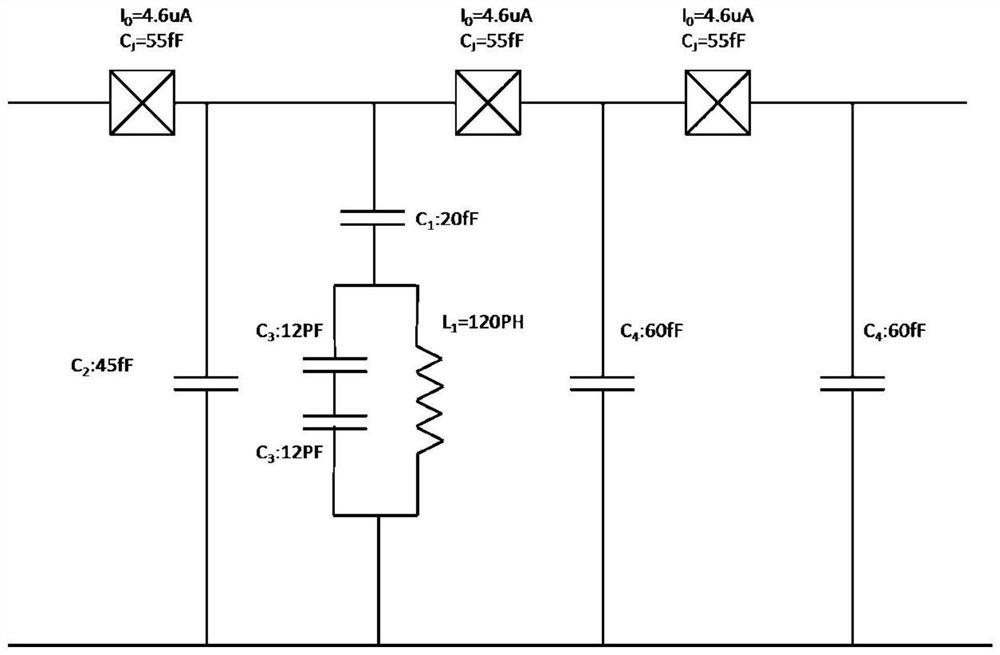

[0036] figure 1 Schematic diagram of the structure of a Josephson traveling wave amplifier. The Josephson traveling wave amplifier is a three-layer film structure, including two layers of metal layers and an intermediate dielectric layer (the dark part in the figure shows the first metal layer, the grid structure in the figure is the second metal layer, and the intermediate dielectric layer Not shown); wherein the first metal layer is made of aluminum thin film material, and the lower panel, inductor and ground plane of the capacitor are prepared by ultraviolet lithography; the second metal layer is prep...

Embodiment 2

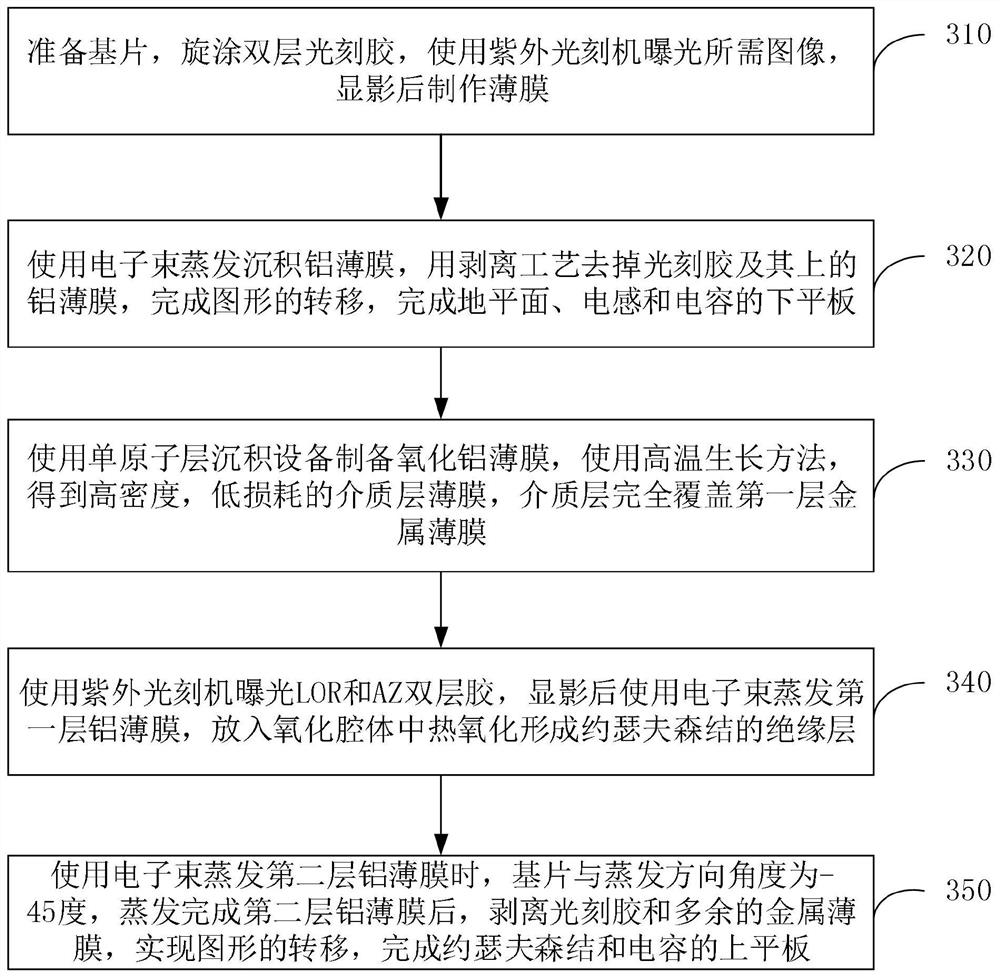

[0043] Embodiment 2 of the present application provides a method for preparing a Josephson traveling wave amplifier, such as image 3 shown, including:

[0044] Step 310, preparing the substrate, spin-coating a double-layer photoresist, exposing the required image with an ultraviolet lithography machine, and making a thin film after developing;

[0045] The devices to be used in this application include monoatomic layer deposition equipment, ultraviolet lithography machine and electron beam evaporation equipment. The devices of this application are all prepared on an undoped intrinsic silicon substrate, the substrate size is 6mm×6mm, and the substrate thickness is 0.5mm. Since this silicon substrate is not doped, the loss is very low, and the entire device The length of the transmission line is about 30mm, and the attenuation of the microwave on the transmission line can be controlled below 1dB; after preparing the substrate, spin-coat the double-layer photoresist, generally ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com