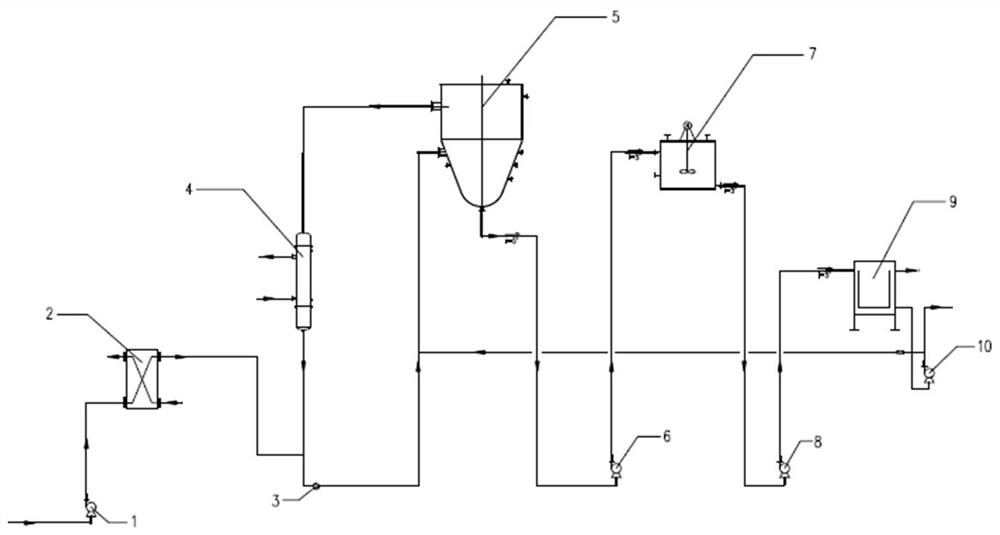

Sodium sulfide continuous cooling crystallization system and process

A technology of cooling crystallization and sodium sulfide, which is applied in the directions of heat exchange cooling crystallization, crystallization separation, sulfur compounds, etc., can solve problems such as being unfavorable to the health of operators, complicated preparation methods of sodium sulfide, and physical injuries of operators, so as to protect personal health. , The effect of reducing manual labor and product quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Concentrate the sodium sulfide solution to 135°C with a concentration of 35%, and then pump it to the plate heat exchanger through the feed pump, and pre-cool the sodium sulfide concentrate through the mother liquor. After pre-cooling, the temperature of the concentrated solution is 105°C. The liquid is sent to the continuous cooling crystallization system for cooling and crystallization, the temperature difference between the sodium sulfide concentrated liquid and the cooling water is kept at 6°C, the circulation rate is 80 times the feed amount, and the temperature of the sodium sulfide feed liquid in the crystallizer is maintained at 65°C, and the solid content After staying in the crystallizer for 4 hours, the material is discharged through the discharge pump. After discharging, the sodium sulfide crystal slurry is sent to the crystal slurry tank for buffering, and the buffered crystal slurry is transported to the centrifuge for solid-liquid separation through the cry...

Embodiment 2

[0055] Concentrate the sodium sulfide solution to 132°C with a concentration of 38%, then pump it to the plate heat exchanger through the feed pump, and pre-cool the sodium sulfide concentrate through the mother liquor. After pre-cooling, the temperature of the concentrate is 103°C, and then the concentrated The liquid is sent to the continuous cooling crystallization system for cooling and crystallization, the temperature difference between the sodium sulfide concentrated liquid and the cooling water is kept at 4°C, the circulation rate is 100 times the feed amount, and the temperature of the sodium sulfide feed liquid in the crystallizer is maintained at 60°C, and the solid content After staying in the crystallizer for 6 hours, the material is discharged through the discharge pump. After discharging, the sodium sulfide crystal slurry is sent to the crystal slurry tank for buffering, and the buffered crystal slurry is transported to the centrifuge for solid-liquid separation th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com