Reinforced magnesium-based composite material and preparation method thereof

A composite material and magnesium alloy technology, applied in the field of reinforced magnesium-based composite materials and their preparation, can solve the problems of low content of nano-silicon carbide particles, low infiltration rate, affecting the infiltration of molten metal liquid, etc., and achieve enhanced tensile strength. , the effect of increasing the infiltration rate and increasing the porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

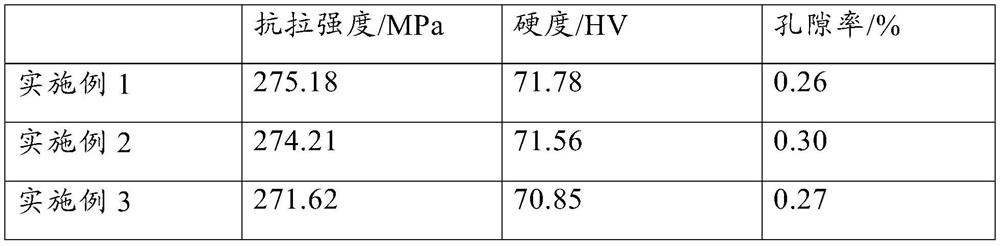

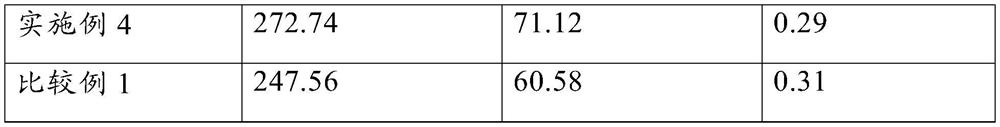

Examples

Embodiment 1

[0032] A method for preparing a reinforced magnesium-based composite material, comprising the following steps:

[0033] S1. Preparation of modified silicon carbide powder

[0034] Add silicon carbide to hydrofluoric acid and soak for 24 hours, then take out silicon carbide, wash with water until the pH value is 6.5-7.0, that is, neutral, dry, vacuum ball mill, and sieve through a 625-mesh sieve to obtain modified silicon carbide Powder: Porous silicon carbide powder is obtained by hydrofluoric acid modification, and the particle size of the powder is less than 20 μm.

[0035] S2, prepare the AIP isopropanol solution of 60wt%

[0036] Add aluminum isopropoxide (AIP) into the isopropanol solution, and mix evenly with ultrasonic vibration to obtain the product;

[0037] S3. Under the condition of ultrasonic stirring, add modified silicon carbide powder to 60wt% AIP isopropanol solution, wherein the mass ratio of AIP to modified silicon carbide powder is 1:0.6; react at 85°C for...

Embodiment 2

[0046] A method for preparing a reinforced magnesium-based composite material, comprising the following steps:

[0047]S1. Preparation of modified silicon carbide powder

[0048] Add silicon carbide to hydrofluoric acid and soak for 36 hours, then take out silicon carbide, wash with water until the pH value is 6.5-7.0, dry, vacuum ball mill, and sieve through a 625-mesh sieve to obtain modified silicon carbide powder; Hydrofluoric acid modification obtains porous silicon carbide powder, and the particle size of the powder is less than 20 μm.

[0049] S2, prepare the AIP isopropanol solution of 70wt%

[0050] Add aluminum isopropoxide (AIP) into the isopropanol solution, and mix evenly with ultrasonic vibration to obtain the product;

[0051] S3. Under the condition of ultrasonic stirring, add modified silicon carbide powder to 70wt% AIP isopropanol solution, wherein the mass ratio of AIP to modified silicon carbide powder is 1:0.5; react at 100°C for 3.5 h;

[0052] After ...

Embodiment 3

[0061] A method for preparing a reinforced magnesium-based composite material, comprising the following steps:

[0062] S1. Preparation of modified silicon carbide powder

[0063] Add silicon carbide to hydrofluoric acid and soak for 12 hours, then take out silicon carbide, wash with water until the pH value is 6.5-7.0, dry, vacuum ball mill, and sieve through a 625-mesh sieve to obtain modified silicon carbide powder; Hydrofluoric acid modification obtains porous silicon carbide powder, and the particle size of the powder is less than 20 μm.

[0064] S2, prepare the AIP isopropanol solution of 50wt%

[0065] Add aluminum isopropoxide (AIP) into the isopropanol solution, and mix evenly with ultrasonic vibration to obtain the product;

[0066] S3. Under the condition of ultrasonic stirring, add modified silicon carbide powder to 50wt% AIP isopropanol solution, wherein the mass ratio of AIP to modified silicon carbide powder is 1:0.8; react at 70°C for 8h ;

[0067] After th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com