A kind of three-dimensional cross-linked network gel polymer electrolyte membrane and its preparation method and application

A gel polymer, three-dimensional cross-linking technology, used in non-aqueous electrolytes, solid electrolytes, electrolyte immobilization/gelation, etc., can solve the problem of increasing the interface impedance between the polymer electrolyte and the electrode, reducing the specific energy density of the battery, reducing the ionic conductivity and other issues, to achieve the effect of promoting fast transport, improving mechanical properties, and increasing ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A method for preparing a three-dimensional crosslinked network gel polymer electrolyte membrane, comprising the following steps:

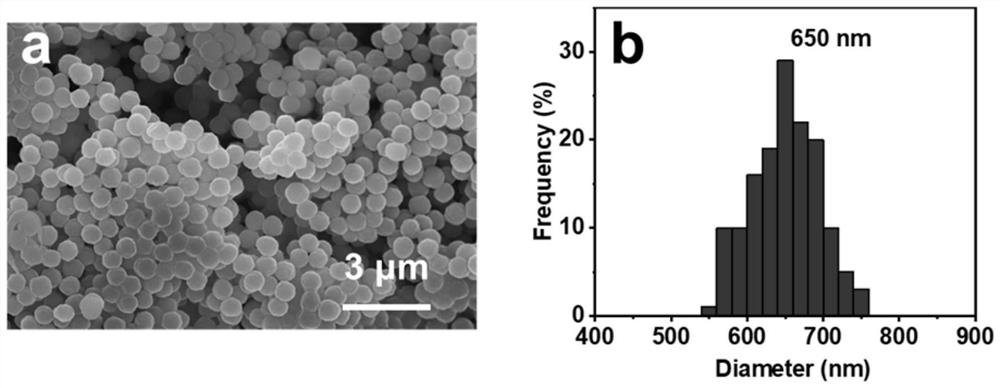

[0060] Step (1): Mix 12.25mL of 4-chloromethylstyrene and 0.25mL of divinylbenzene and inject it slowly into 248mL of deionized water with a micro-injection pump, heat up to 75°C after mixing, and weigh 0.21g Azobisisobutylamidine hydrochloride (V50 initiator) was dissolved in 2 mL of deionized water, injected into the reaction system with a needle, refluxed at 75°C for 4 hours under an inert atmosphere, washed with ethanol and water after centrifugation, and dried in vacuum at 40°C , to obtain an intermediate product one;

[0061] Step (2): Add 3.5 g of the intermediate product prepared in step (1) into 112 mL of 1,2-dichloroethane, stir slowly overnight to allow it to fully swell, raise the temperature to 80 ° C, and add 3.7 g of anhydrous trichloro Iron chloride was refluxed for 24 hours, then acetone / hydrochloric acid / water mixed solven...

Embodiment 2

[0079] A method for preparing a three-dimensional crosslinked network gel polymer electrolyte membrane, comprising the following steps:

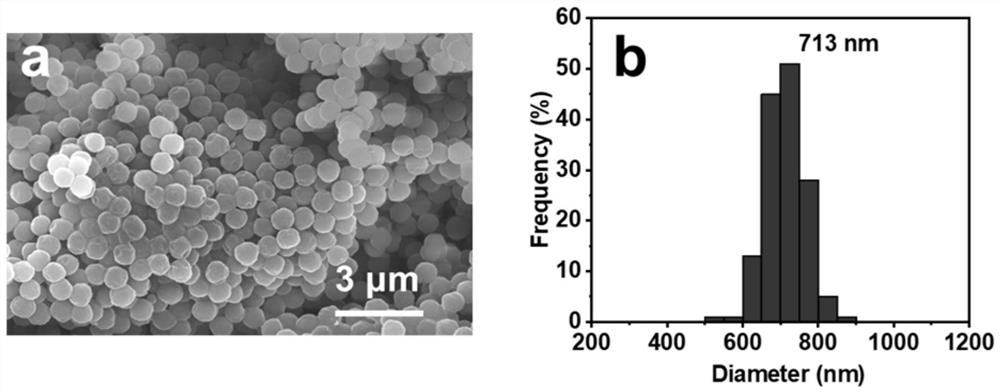

[0080] Step (1): Mix 12.25mL of 4-chloromethylstyrene and 0.25mL of divinylbenzene and inject it slowly into 248mL of deionized water with a micro-injection pump, heat up to 75°C after mixing, and weigh 0.21g Azobisisobutylamidine hydrochloride (V50 initiator) was dissolved in 2 mL of deionized water, injected into the reaction system with a needle, refluxed at 75°C for 4 hours under an inert atmosphere, washed with ethanol and water after centrifugation, and dried in vacuum at 40°C , to obtain an intermediate product one;

[0081] Step (2): Add 3.5 g of the intermediate product prepared in step (1) into 112 mL of 1,2-dichloroethane, stir slowly overnight to allow it to fully swell, raise the temperature to 80 ° C, and add 3.7 g of anhydrous trichloro Iron chloride was refluxed for 24 hours, then acetone / hydrochloric acid / water mixed solven...

Embodiment 3

[0086] A method for preparing a three-dimensional crosslinked network gel polymer electrolyte membrane, comprising the following steps:

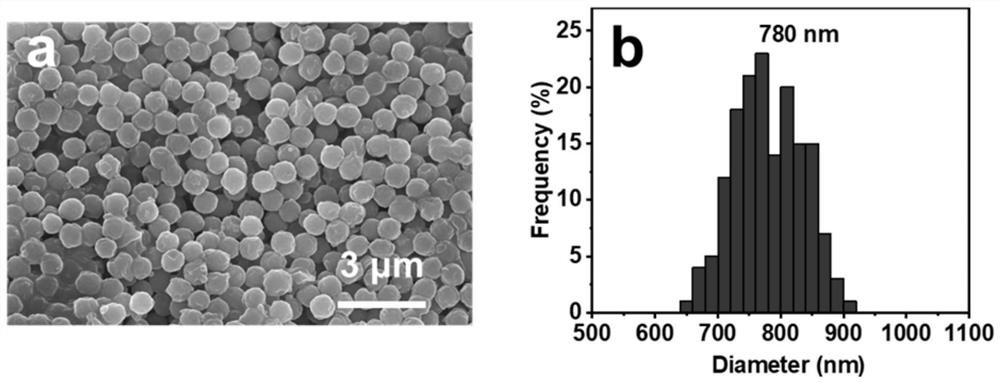

[0087] Step (1): Mix 12.25mL of 4-chloromethylstyrene and 0.25mL of divinylbenzene and inject it slowly into 248mL of deionized water with a micro-injection pump, heat up to 75°C after mixing, and weigh 0.21g Azobisisobutylamidine hydrochloride (V50 initiator) was dissolved in 2 mL of deionized water, injected into the reaction system with a needle, refluxed at 75°C for 4 hours under an inert atmosphere, washed with ethanol and water after centrifugation, and dried in vacuum at 40°C , to obtain an intermediate product one;

[0088] Step (2): Add 3.5 g of the intermediate product prepared in step (1) into 112 mL of 1,2-dichloroethane, stir slowly overnight to allow it to fully swell, raise the temperature to 80 ° C, and add 3.7 g of anhydrous trichloro Iron chloride was refluxed for 24 hours, then acetone / hydrochloric acid / water mixed solven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com