Platinum-loaded nano cage-shaped zirconium oxide-cobaltosic oxide solid solution as well as preparation and application thereof in toluene thermocatalytic treatment

A technology of tricobalt tetroxide and zirconia, applied in metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, gas treatment, etc., can solve problems such as differential thermal stability, and achieve uniform pore size and controllable structure , Increase the effect of reactive active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 The preparation of nano-cage zirconia-cobalt tetroxide solid solution, the specific steps are as follows:

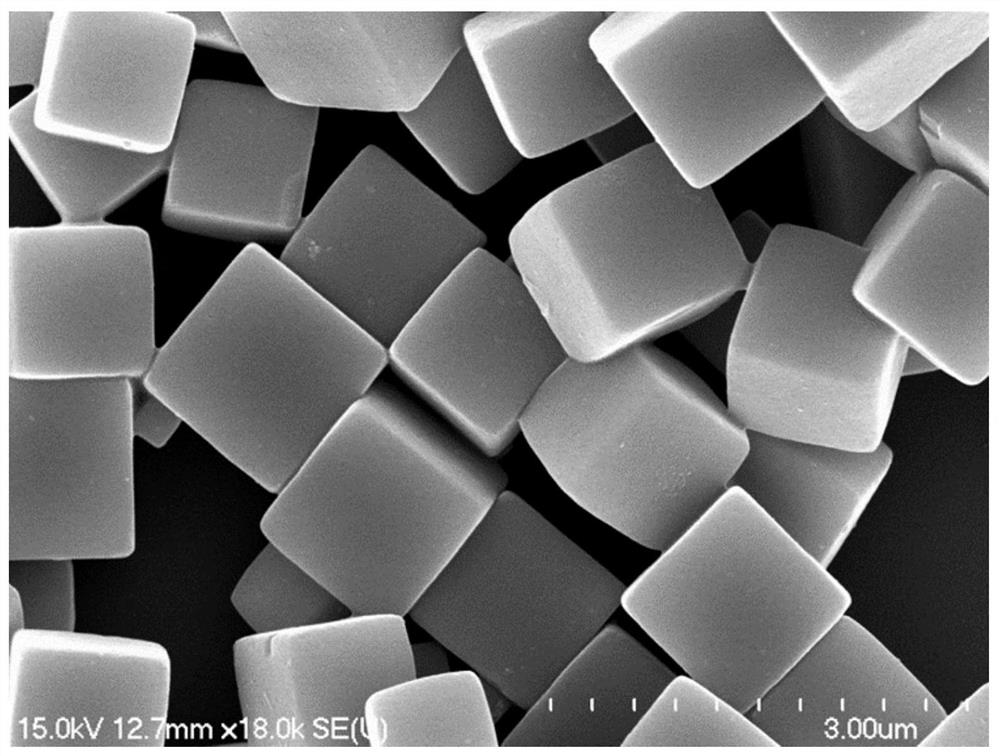

[0037] CuSO 4 ∙5H 2 O (1.5 mmol) was dissolved in 80 ml of ultrapure water, then sodium citrate (0.5 mmol) was added to the above solution with stirring; then, another 20 ml of NaOH (1.25M) was added with stirring and stirred for 15 min , and 50 ml of ascorbic acid (0.03M) was put into the suspension under stirring for 15 min; finally, the obtained mixed solution was aged at 50°C for 1 h; the precipitate was collected by centrifugation and washed three times with ultrapure water and ethanol , dried to obtain Cu 2 O Nanocube.

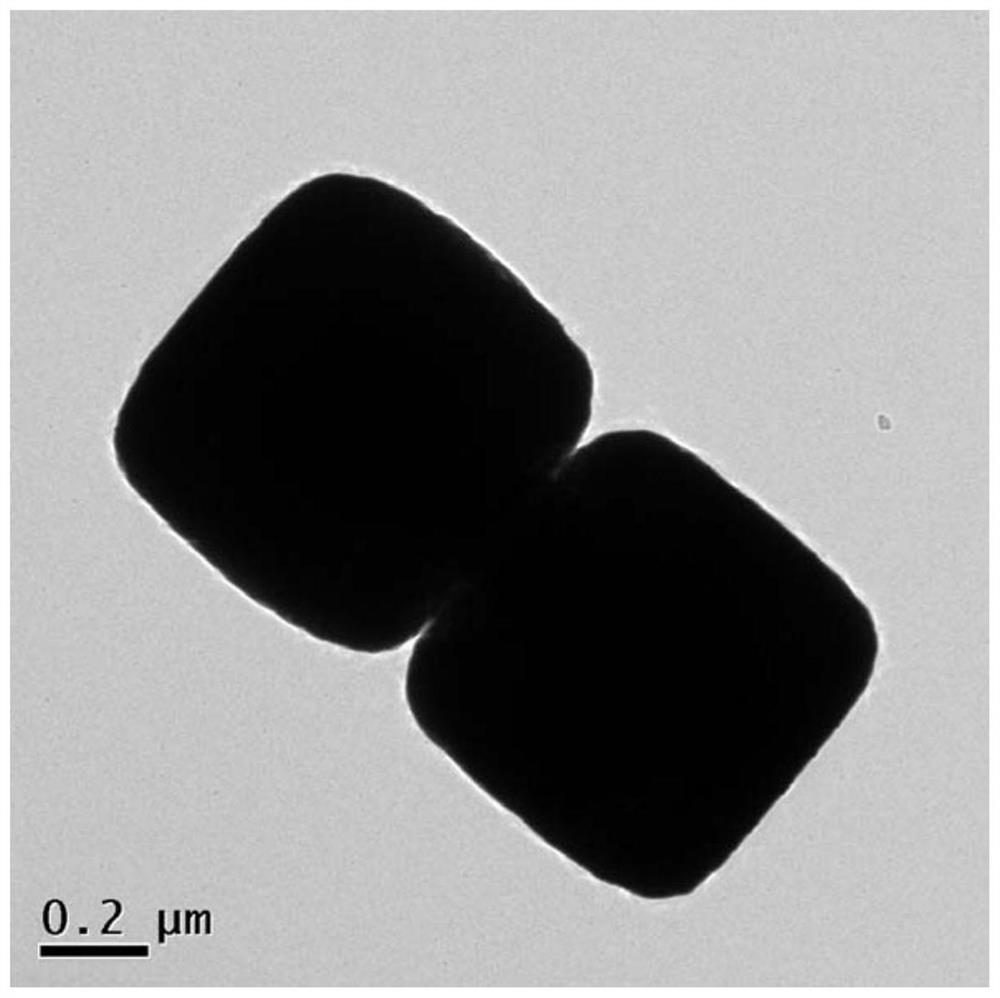

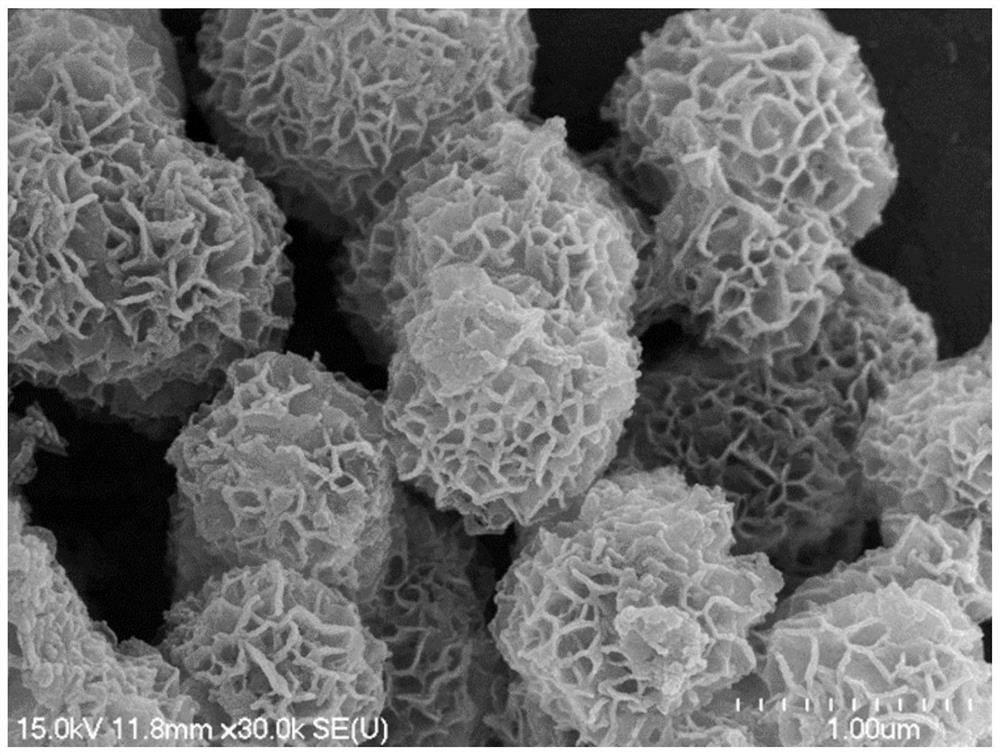

[0038] At room temperature, 25 mg of Cu prepared above 2 O nanocubes, 1 mg ZrOCl 2 ·8H 2 O and 15 mg CoCl 2 ∙6H 2 O was dispersed in 40 mL of ethanol / HO solvent (volume ratio = 1:1), and 1.33 g of PVP (M w = 40000) sonicated for 20 min. Then, with stirring, 25 mL of 1M Na 2 S 2 o 3 The solution was slowly added dropwi...

Embodiment 2

[0040] Example 2 The preparation of platinum-loaded nano-cage zirconia-cobalt tetroxide solid solution, the specific steps are as follows:

[0041] Pt nanoparticles were successfully prepared onto the support by the ethylene glycol reduction method. 8.06 mg of Pt(acac) 2 and 200mg Zr 0.1 The Co solid solution was added to a mixed solvent containing 30 ml DMF and 20 ml EG, then dispersed by sonication for 20 min and magnetically stirred for 4 h. The obtained suspension was then transferred to a reactor and heated to 160 °C for 12 h. The powder was collected by centrifugation, washed 3 times with ethanol, and then dried in vacuo at 60 °C overnight to obtain 2.0 wt% Pt / Zr 0.1 Co, that is, nano-cage zirconia-cobalt tetroxide solid solution loaded with platinum. replace Pt(acac) 2 The amount of yPt / Zr with theoretical Pt content of y = 0.5, 1.0, 2.0 wt% was prepared 0.1 Co catalyst.

[0042] attached Figure 5 2.0 wt% Pt / Zr 0.1 SEM images of Co composites, attached Figur...

Embodiment 3

[0046] The thermal catalytic conditions of the zirconia-cobalt tetroxide solid solution nanocage composite material loaded with platinum metal nanoparticles to toluene gas are: the concentration of toluene is 50 ppm (air is used as filling gas, purchased from Messer Air Liquide Co., Ltd.), and the amount of catalyst is 50 mg, the catalyst was fixed on a fixed-bed reactor through a U-shaped tube, and the catalytic effect of the composite material on toluene gas under heating conditions was analyzed by gas chromatography, and the test condition was 36000 ml / (h∙g).

[0047] Figure 7 It is the thermocatalytic effect curve figure of zirconia-cobalt tetroxide solid solution to toluene gas; Figure 8 It is a graph showing the thermocatalytic effect of zirconia-cobalt tetroxide solid solution nanocage composites loaded with platinum metal nanoparticles on toluene gas. attached by Figure 8 It can be seen that the present invention can be applied to the conversion of toluene at low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com