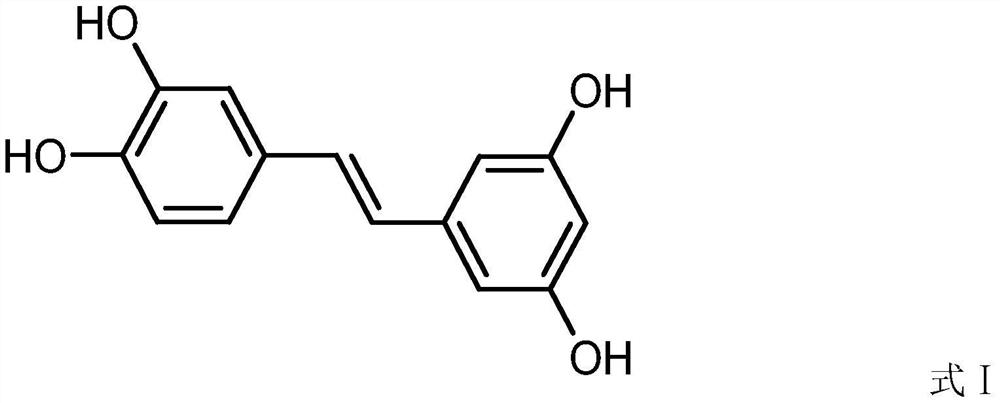

Extraction method of piceatannol in rhubarb medicinal materials, microcapsule molecular embedding method and application of piceatannol in cosmetics

A technology of piceatanol and its extraction method, which is applied in the direction of cosmetics, microcapsule preparations, cosmetic preparations, etc., can solve the problems of easy oxidative discoloration, affecting the absorption effect of the human body, and poor water solubility of molecules, so as to achieve protection and oxidative discoloration, and improve Effect of embedding rate, water solubility, and low skin sensitization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 extracts picetanol crystals from rhubarb in Lhasa

[0046] First, crush 1000 carats rhubarb dried rhizomes into 20-mesh granules, weigh 15 grams of cellulase, 10 grams of amylase, 5 grams of pectinase and 100 grams of warm water at 42°C, mix the above three enzymes with water, and stir Spray it evenly on the plant material, and keep it in a 42°C incubator for 36 hours to carry out enzymatic treatment.

[0047] The aforementioned enzymolysis-treated plant material was taken out, sprayed with 10% sodium carbonate solution to adjust the pH of the material to 10, added 12 kg of 73% (v / v) alcohol, and used a microwave extraction process (microwave power 650W, extraction time 180s,) to The material is extracted at room temperature (25-30°C).

[0048] After filtering the extract, add an appropriate amount of 5% lactic acid aqueous solution to adjust the pH=7, concentrate under reduced pressure to form an extract, add 10 times of pure water to dissolve back to obt...

Embodiment 2

[0049] Example 2 Preparation of Microcapsule Molecular Embedding Body by Picetanol Crystals

[0050] 1. Preparation of glucosyl-β-cyclodextrin (Glu-β-CD):

[0051] Step 1. Mix 20% maltose syrup and β-cyclodextrin powder according to 4:1 to form a homogeneous slurry, add 1-3% (w / w) pullulanase by total weight, and 38°C, 60% relative humidity in a constant temperature and humidity box for 72 hours, then put the prepared sample in a 50°C constant temperature box for 2 hours to stop the enzyme conversion, and obtain an intermediate product: glucosyl-β-cyclodextrin slurry .

[0052] Step 2. Add 1-3% (w / w) glucoamylase to the glucosyl-β-cyclodextrin slurry material, stir and mix evenly, keep stirring in a constant temperature and humidity box at 40°C and a relative humidity of 60% for 48 hours , Glucosyl-β-cyclodextrin is hydrolyzed under the action of glucoamylase to generate glucose and glucosyl-β-cyclodextrin.

[0053] Step 3: UF4050 ultrafiltration membrane is used to purify ...

Embodiment 3

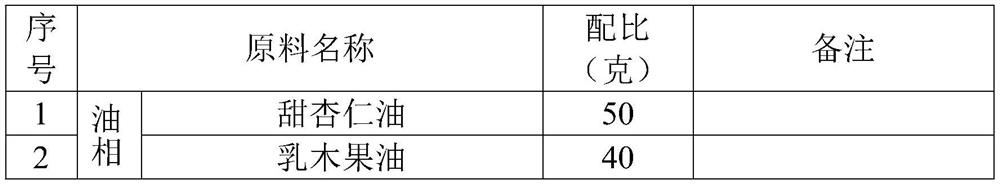

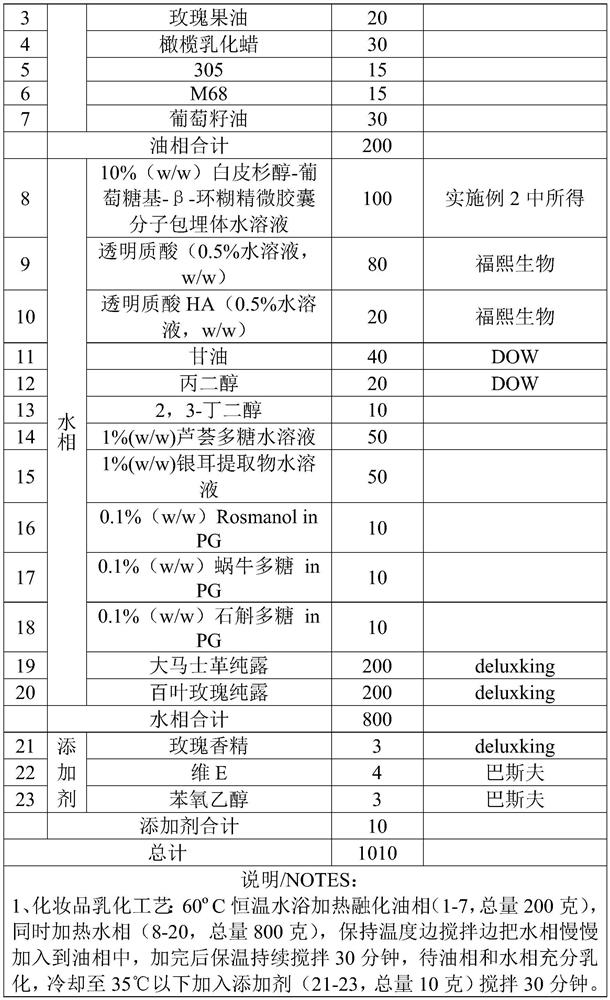

[0059] Example 3 Picetanol Microcapsule Molecular Embedding Body Made Face Cream

[0060] Face cream product containing natural picatanol microcapsule molecular embedding body microcapsule molecular embedding body and preparation method

[0061]

[0062]

[0063]

[0064] Evaluation of application effect: In view of the poor solubility of picetanol in water (0.3 g / liter of picetanol), in embodiment 1, picetanol is no longer added in the traditional way, but adopts modified ring The dextrin is firstly prepared and embedded into molecular microcapsule molecular embedding body microcapsule molecular embedding body, and the microcapsule molecular embedding body is diluted with water first, and picetanol microcapsule molecular embedding body microencapsulation is added from the water phase. Capsule molecular embedding body, in the emulsification process of cosmetics, the oil phase is further encapsulated relative to the water phase, forming a binary embedding structure of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com