Helical carbon nanocoil/core-shell magnetic nanoparticle composite material, preparation method and application in the field of electromagnetic waves

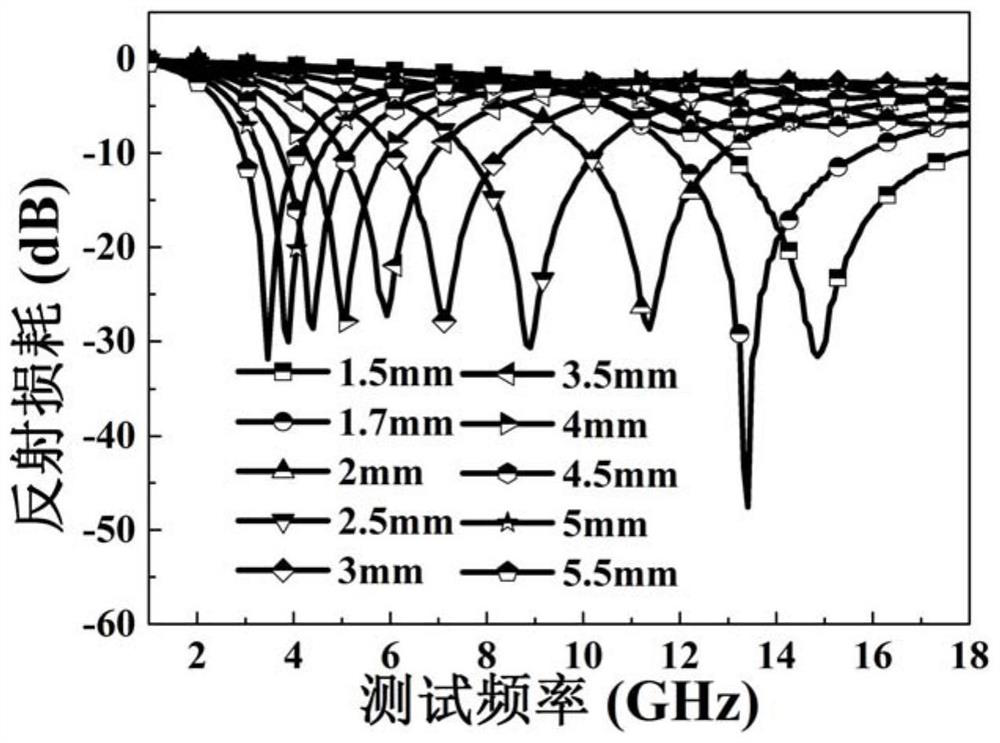

A technology of magnetic nanoparticles and carbon nanocoils, applied in nanomagnetism, nanotechnology, nanotechnology, etc., can solve the problems of restricting large-scale preparation economy, low maximum loss, large coating thickness, etc., and achieve suitable mass preparation , increase the magnetic loss, the effect of high absorption strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

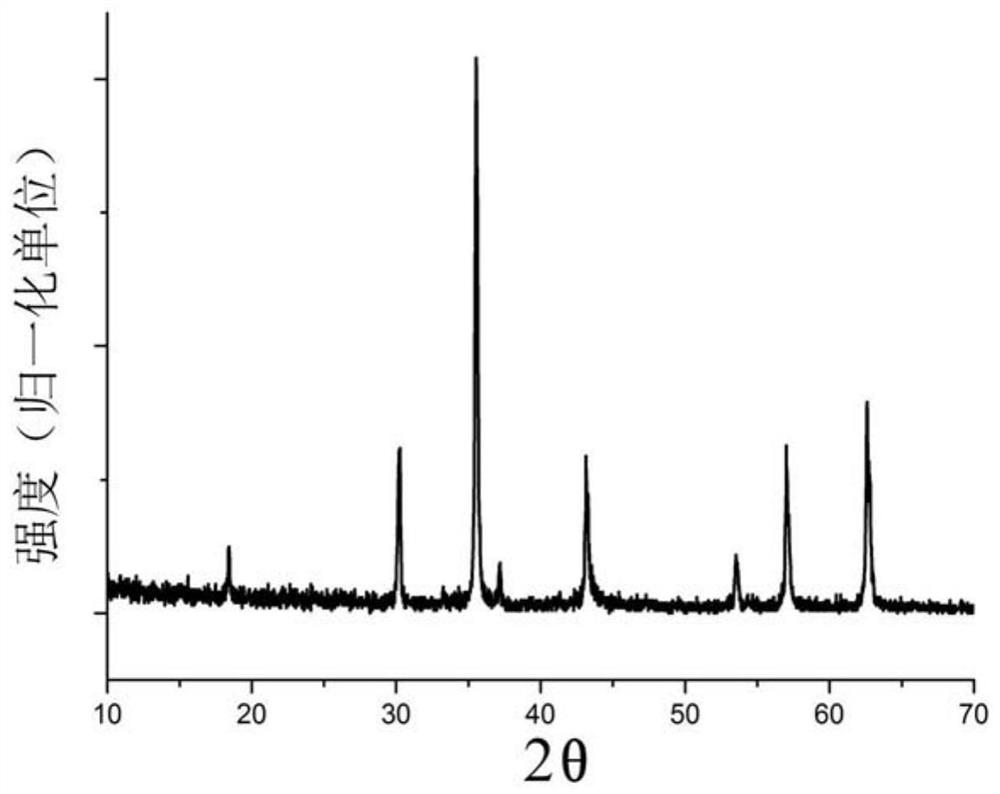

[0034] (1) CNC is prepared by CVD method (Reference: Patent Publication No. 109201068A, named as a preparation method and application of a catalyst for carbon nanocoil synthesis with reduced by-product carbon layer).

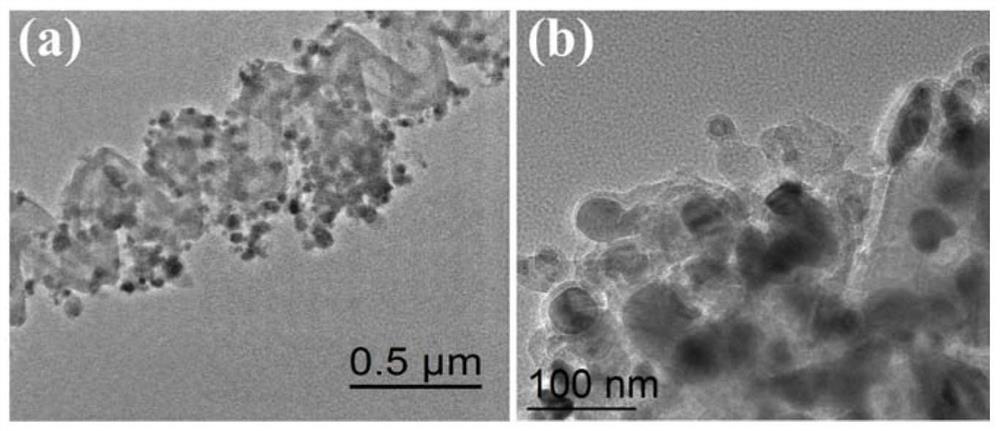

[0035] (2) Disperse 100mg of CNC powder in 25ml of absolute ethanol, and ultrasonically disperse it evenly for 1h, press CNC:Fe 2+ Add soluble Fe at a mass ratio of 1:2 2+ (FeCl 2 ·5H 2 0), dropwise add the polyethylene glycol solution (PEG) of 10ml dilute ammonia water (mass fraction 2.5wt%), 0.2ml hydrogen peroxide (mass fraction 28wt%) 10ml (50g / L), then mixed solution ultrasonic 10min, then The resulting mixed solution was poured into the lining of a polytetrafluoroethylene reactor, and the reactor was placed at 160°C for 8 hours, and then the product was rinsed three times with deionized water and alcohol suction filtration, and dried to obtain CNC / Fe 3 o 4 Complex.

[0036] (3) get the CNC / Fe prepared by process (2) 3 o 4 The composite is placed in ...

Embodiment 2

[0041] (1) The CNC preparation method is the same as that of the implementation example (1).

[0042] (2) Disperse 100mg of CNC powder in 25ml of ethylene glycol, and ultrasonically disperse it for 1h, press CNC:Fe 3+ Add soluble Fe at a mass ratio of 1:1 3+ (Fe(NO 3 ) 3 ·5H 2 O), then add 0.5g polyethylene glycol, 1.5g sodium acetate, ultrasonic the mixed solution for 10min, then pour the gained mixed solution into the lining of polytetrafluoroethylene reactor, and place the reactor at 140°C for reaction After 30h, the resulting product was rinsed 3 times with deionized water and alcohol suction filtration, and after drying, the CNC / Fe 3 o 4 Complex.

[0043] (3) get the CNC / Fe prepared by process (2) 3 o 4 The composite is placed in a quartz tube, and the Fe 3 o 4 Surface covered with carbon. The reaction temperature was 400° C., and the reaction gases were argon with a flow rate of 100 sccm and acetylene with a flow rate of 10 sccm (the flow rate ratio of inert g...

Embodiment 3

[0048] (1) The CNC preparation method is the same as that of the implementation example (1).

[0049] (2) Disperse 100mg of CNC powder in 25ml of absolute ethanol, and ultrasonically disperse it evenly for 1h, press CNC:Fe 2+ Add soluble Fe at a mass ratio of 1:4 2+ (FeCl 2 ·5H 2 0), dropwise add the polyethylene glycol solution (PEG) of 10ml dilute ammonia water (mass fraction 2.5wt%), 0.2ml hydrogen peroxide (mass fraction 28wt%) 10ml (50g / L), then mixed solution ultrasonic 10min, then The resulting mixed solution was poured into the lining of a polytetrafluoroethylene reactor, and the reactor was placed at 220°C for 4 hours to react, and then the product was rinsed three times with deionized water and alcohol suction filtration, and dried to obtain CNC / Fe 3 o 4 Complex. (3) get the CNC / Fe prepared by process (2) 3 o 4 The composite is placed in a quartz tube, and the Fe 3 o 4 Surface covered with carbon. The reaction temperature was 600° C., and the reaction gases...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| absorption bandwidth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com